What is integrated production?

Integrated production signifies a system in which all manufacturing processes, such as machining, inspection, and assembly, are handled in an integrated manner within the company.

Developed from our forging technology, FINECS is able to handle press working, plating and surface treatment, molding, integrated molding, and automated assembly through our integrated in-house manufacturing system.

FINECS' unique integrated production system leads to optimal QCD proposals.

With our in-house designed and manufactured automatic assembly machines, dies, and image inspection equipment, we are able to make proposals with the “FINE DIFFERENCE” by utilizing our know-how and technology, quality capabilities, and speedy response.

Advantages of Integrated Production

- Quality improvement

Each manufacturing process is close to each other, so feedback is quick and high quality can be maintained - Shortening delivery time

Reduction of lead time by collaboration within the same company - Cost reduction

Cost savings achieved by reducing costs and time for side-to-side movement, intermediate inventory, and improving qualit - Dies and equipment manufactured in-house

In-house production of automatic processing machines, dies, image inspection equipment, and other equipment for speedy response

Integrated Production Process

The manufacturing of electronic components can be divided into multiple manufacturing processes, such as “die design” “Pressing” “plating” “insert molding” and “Packaing”. Although it is possible to outsource each of the above manufacturing processes to a different manufacturer, we handle all of them in-house. This contributes to the reduction of various costs incurred by separating the manufacturing processes.

① Die Design

We also design and manufacture precision forging dies pressing dies and molds in-house.

As a result, we can provide a rapid response whenever the reqirements arise for

maintenance, repair or technical prototyping.

② Pressing

Dies designed and manufactured in-house use die components that employ high-precision component processing technology to accommodate a wide variety of connector terminals.

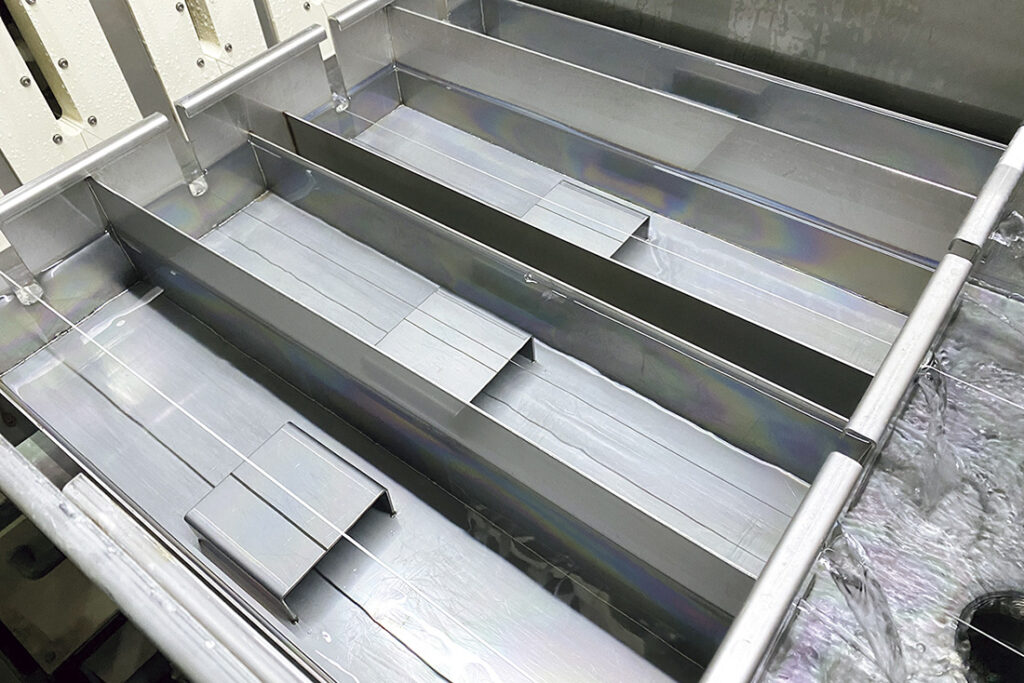

③ Plating process

We have gold, silver, tin, and other plating lines in-house to deliver high-value-added products

with press processing and plating processing.

④ Insert Molding

Our concept is to design a process that requires as little repair work as possible, aiming for “zero” burrs and short shot defects.

⑤ Packaging

We perform the entire process from assembly, inspection, and packaging of insert molding.

Examples of Integrated Production Products

In our integrated production of electronic components, we have established a production system that minimizes variation by shortening the distance between each process and quickly providing feedback between processes, thereby achieving manufacturing with high process capability that does not require full inspection. We also offer competitive proposals based on a total balance including delivery time and cost, as well as synergy effects with forged parts.

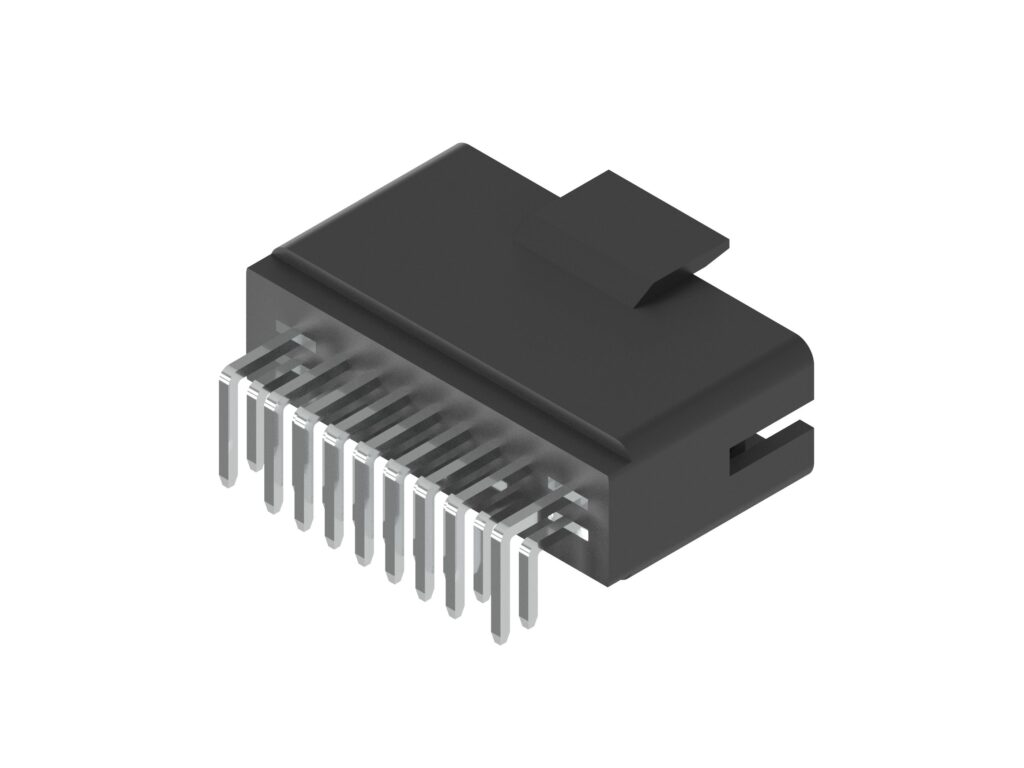

Connector assembly using wire terminals

We are an OEM of connectors that use wire terminals, taking advantage of the know-how we have accumulated over many years of forging operations.

We can provide integrated production from terminal processing to insert molding into connector housings, enabling cost-effective connector OEM production.

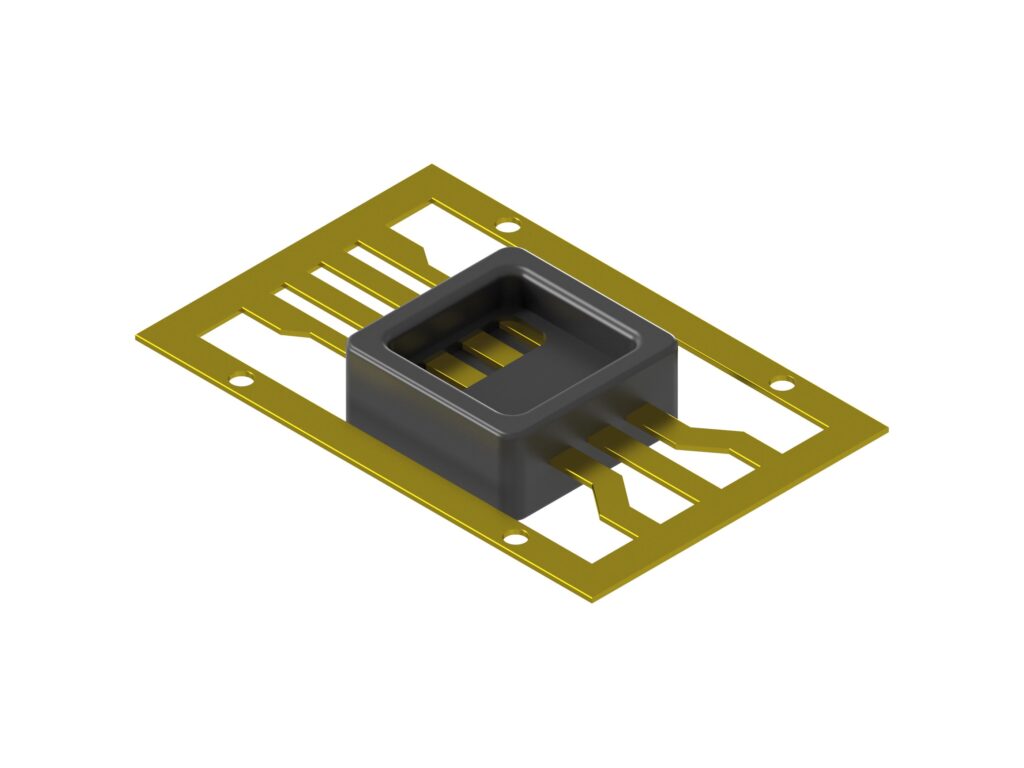

Sensor assemblies using pressed terminals

We can manufacture sensor housings and lead frames used for sensors as sensor OEM.

We can handle the entire process from punching hoop materials by pressing, plating treatment by continuous plating equipment, to hoop insert molding.