Mastering cold forging, composite processing, and automation

Mastering cold forging

Using the deformation processing technology for metal wire rods we have refined over many years, we have developed a mass production system for headed parts, spanning applications from micro pins to thick headed parts for automobiles. We provide a stable supply of products by applying our skills in wire drawing, plating, and barrel finishing. And by utilizing the technology and expertise we have accumulated over the years, we meet industry needs for consumer devices, in-vehicle parts, industrial equipment, and medical and healthcare products.

Production technology for headed parts

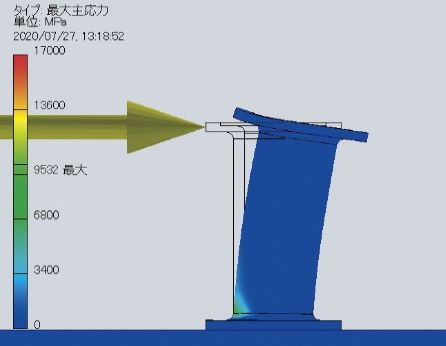

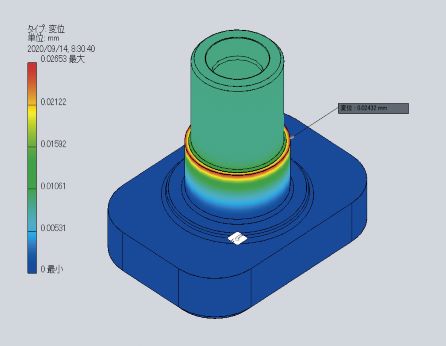

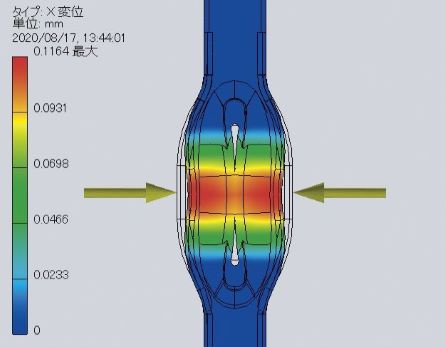

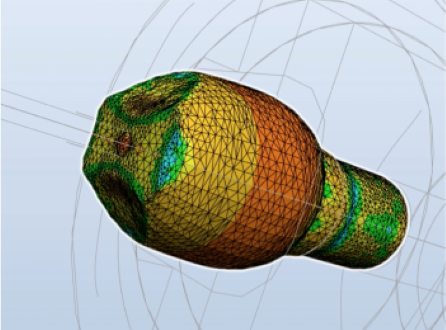

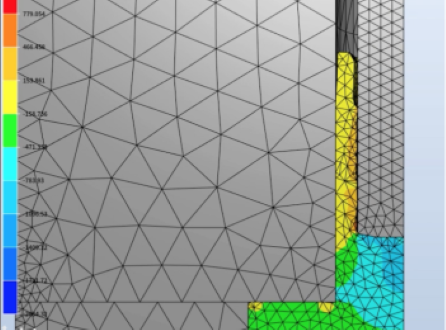

We calculate the optimum processing conditions as we undertake process design and mold design. We perform stress analyses, evaluation tests, process capability measurements and other tasks as we complete the shape of a headed product. The completed piece is then approved to become a mass-produced product.

Stress analysis of headed product

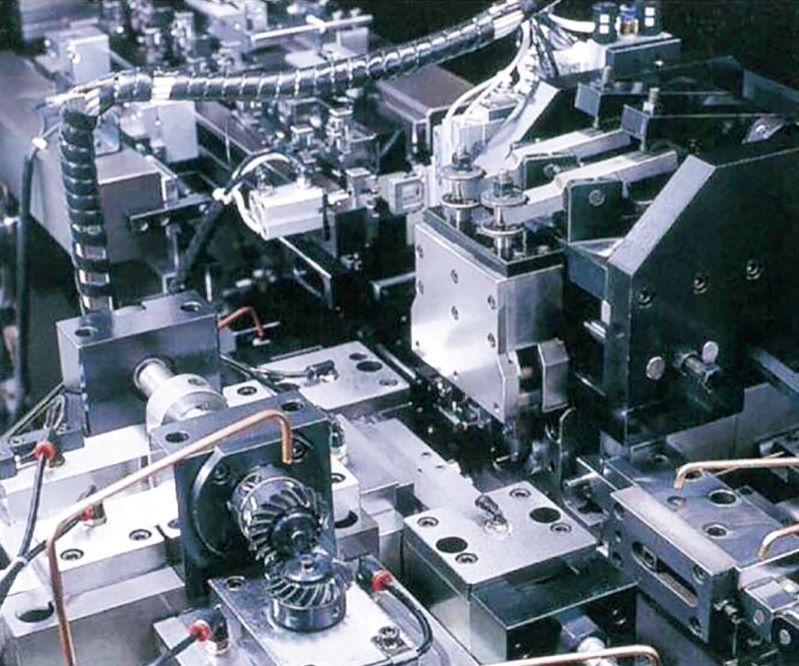

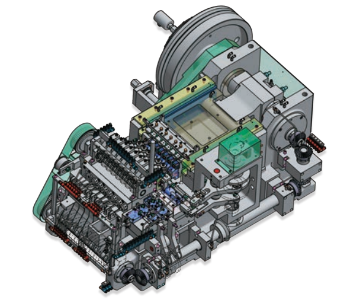

Molds and automated machinery produced in-house

Committed to exceptional quality and micron-level accuracy on a daily basis, we accommodate rapid prototype development, repair, and improvement.

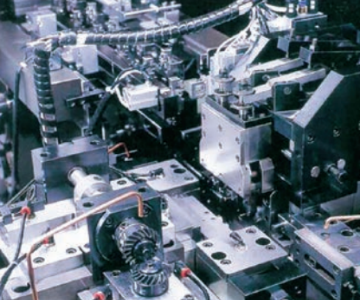

Mastering composite processing

We have established a consistent production line for pressing, plating, molding, insert-molding, and parts assembly of metal strips. We have established a manufacturing system that makes it easier for customers to request specific electronic components. With an integrated production system that maintains high quality, we manufacture high value-added products, OEM supply of electromechanical components, and custom products.

Composite Processing

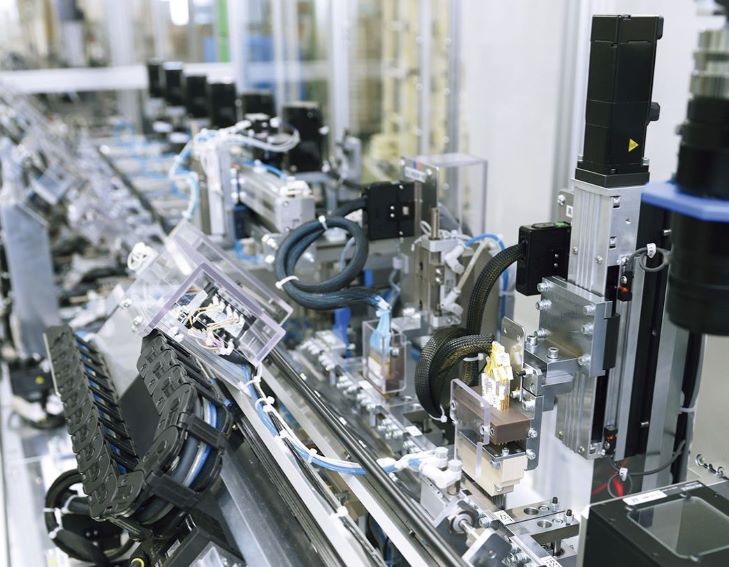

We focus on the automated production of electromechanical components.

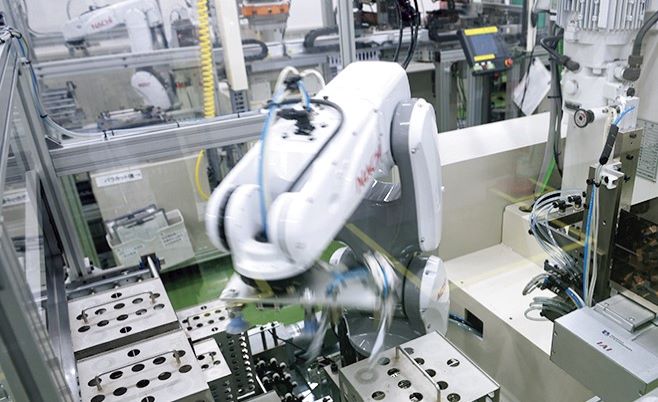

Mastering automation

Producing high-quality components requires high-quality machinery.

In the electronic-component industry, where new products are constantly in demand, the machinery producing them must always be upgraded for higher precision.

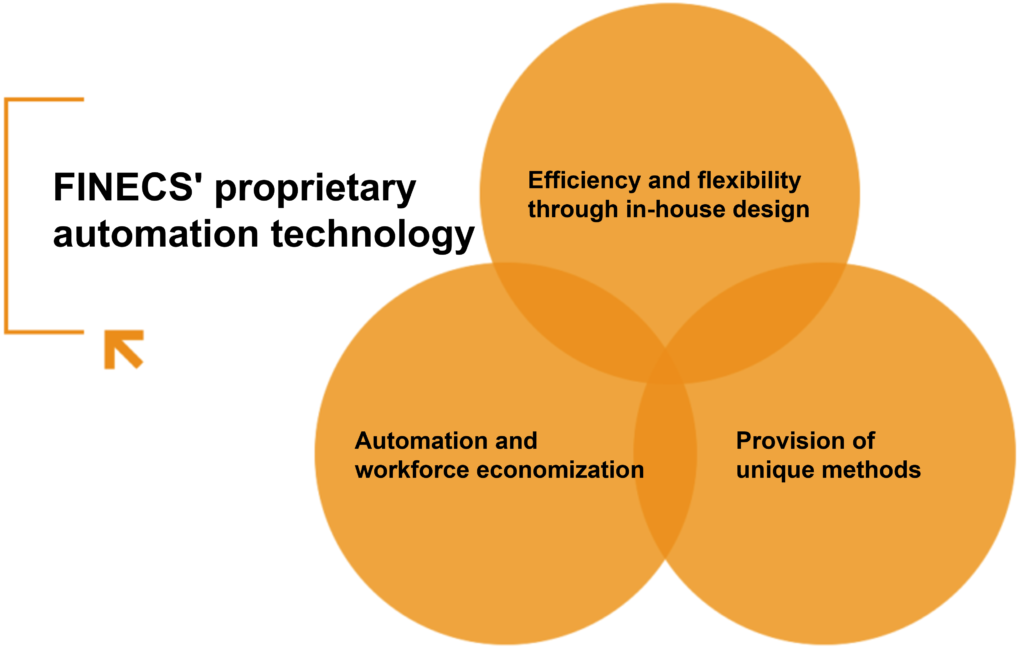

Through the in-house manufacturing of automated production machinery, FINECS responds to customer requests in a quicker and more detailed manner, as well as attaining lower costs through our proprietary automation technology which minimizes manpower, so that we can meet customer expectations.

Furthermore, a wide variety of technologies accumulated over the years allows us to provide solutions unique to FINECS.

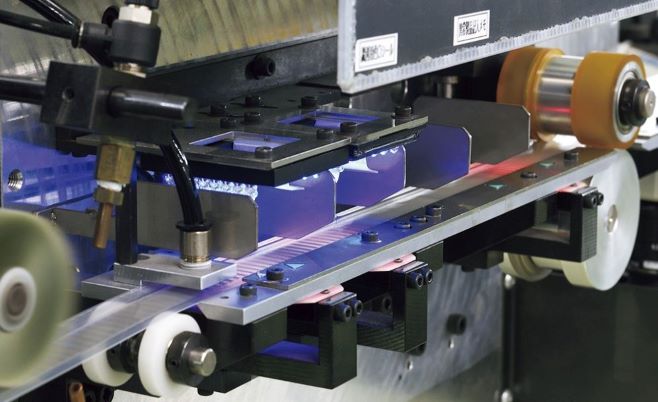

Control Technology & Image Inspection Technology

In order to reduce the workload and implement automation and unmanned operation, we make full use of control and image-inspection technologies as part of our future-oriented approach to manufacturing.

Automated Machinery Production

With our technology and years of experience in automated machinery manufacturing, we ensure low-cost manufacturing of electronic components with consistent quality

Quality Control System

FINECS has introduced various analyzers to maintain stable quality at all times. Our analytical capabilities and high quality are highly evaluated by our customers. Using basic quality control methods, we are constantly improving our analytical and analytical capabilities to make optimal proposals based on data.