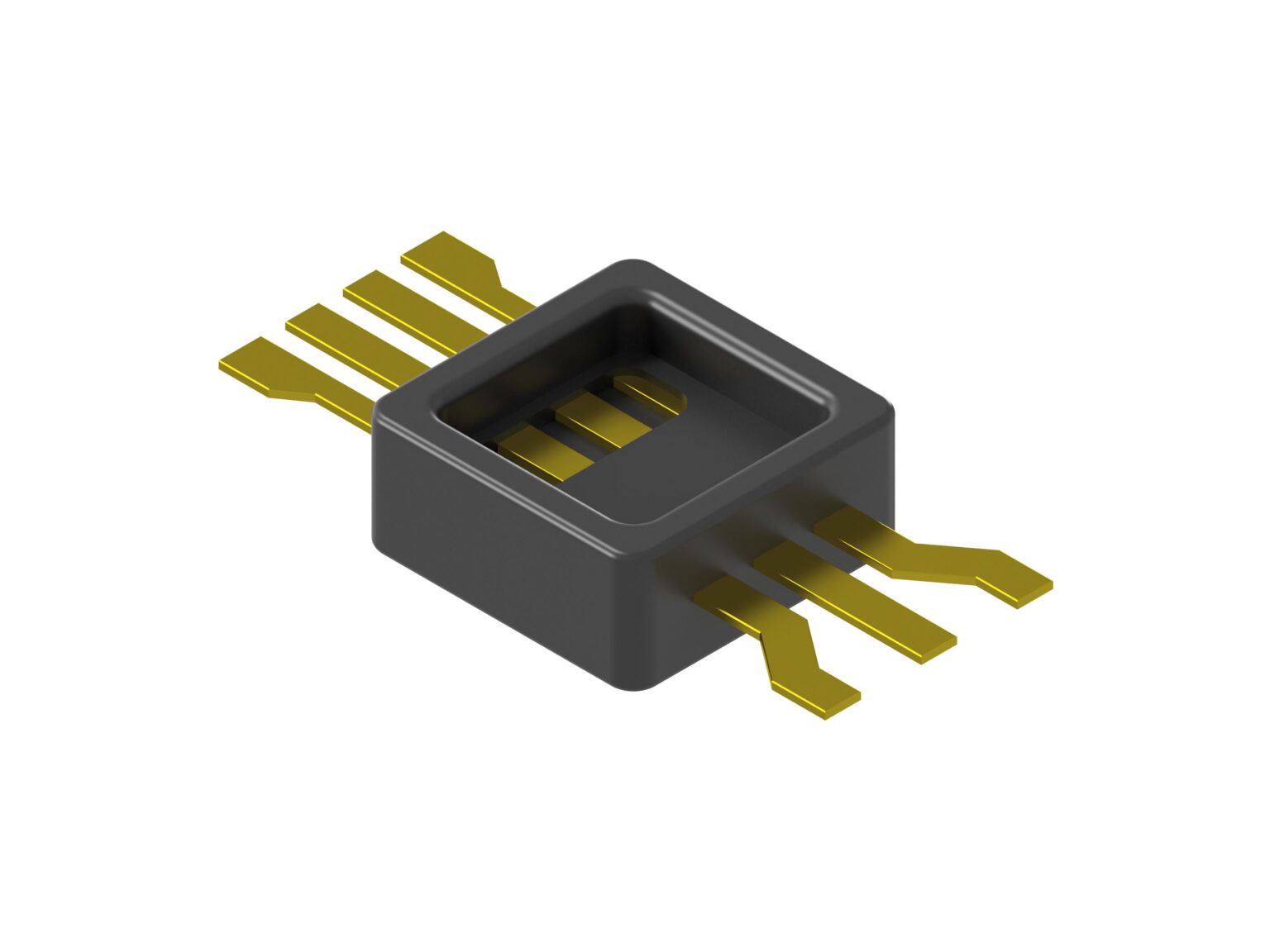

Sensor Assemblies with Pressed Terminals

Product Features

We manufacture electronic mechanical parts such as connectors and sensors by applying high-precision forging technology cultivated over many years, pressing of metal strips, plating surface treatment, integrated forming of these parts, and automated assembly.Our integrated production system with in-house automated machines ensures a stable supply of high quality parts and has earned us the satisfaction and trust of our customers. Our in-house equipment and dies consistently produce a series of processes required for the necessary for manufacturing connectors, sensors, etc, such as press cutting, soft gold plating for wire bonding, insert molding, heat treatment, cutting processes, and image inspection. Robots and other equipment are actively used in the production process to increase the automation ratio.

Reference Specifications

Material

Pressed terminals

Material for lead frames: phosphor bronze, pure copper, brass, etc.

Molded parts

PPS (thermoplastic resin), heat resistance 9T nylon (heat resistance), LCP, etc.

Plating

Ni, Cu (both base)

Soft Au, Ag, Sn (finish)

(Ag plating, Sn plating, etc. are also available)

Shape

Regarding any kind of signal terminal for sensors, we can manufacture lead frames using our pressing technology. We can also add surface treatment ( plating: full, partial, hoop) or insert molding to create sensor cases inside our integrated production line.

We can also supply hoop leadframes by pressing and plating.

Target Markets

Automotive sensors

(air) pressure sensors, tactile sensors, temperature sensors, oxygen sensors, speed sensors, LiDAR sensors, seating sensors, and more

Consumer sensors

image sensors, CCD sensors, magnetic sensors, and more

Plating

To make wire bonding possible, the most common type of plating for lead frames is Ni (base) + soft Au (finish). With a view on the financial side, we offer partial plating for soft gold.

Introduction of FINECS' plating technolog >

Integrated Production

FINECS has earned the satisfaction and trust of its customers by providing a stable supply of high-quality parts through integrated production using in-house automated machines. We have developed from our forging technology, and are able to provide integrated in-house manufacturing that includes stamping, plating, surface treatment, molding, integrated molding, and automated assembly.