Hollow rivets

At FINECS, we manufacture and sell the following products.

We handle mass production quantities from 10K to several 100M / month.

Reference standards

φ2.0~φ8.0mm

※ Please let us know your preferences.

Material

Aluminum, Copper & copper-related

※ Please let us know your preferences.

Product characteristics

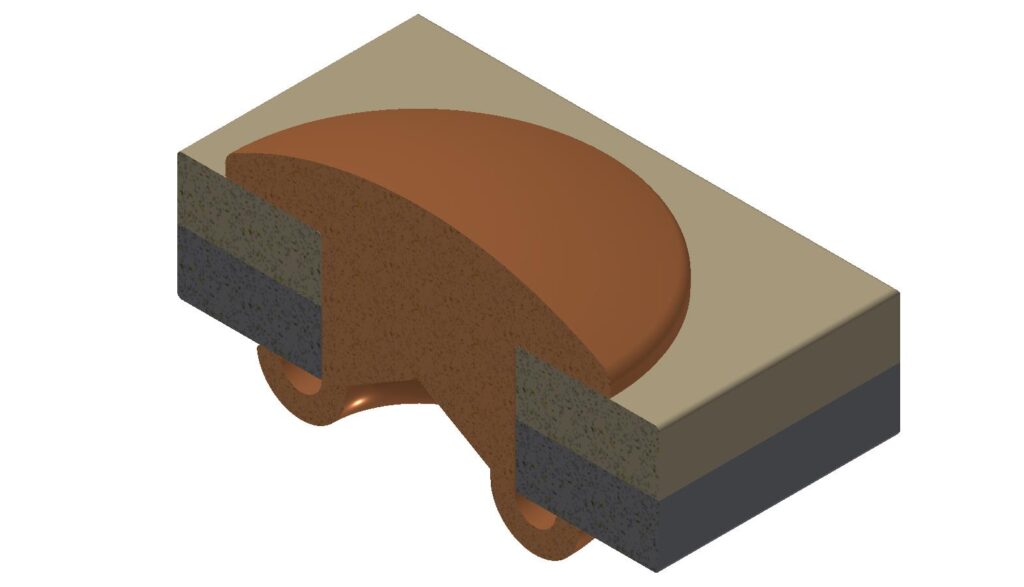

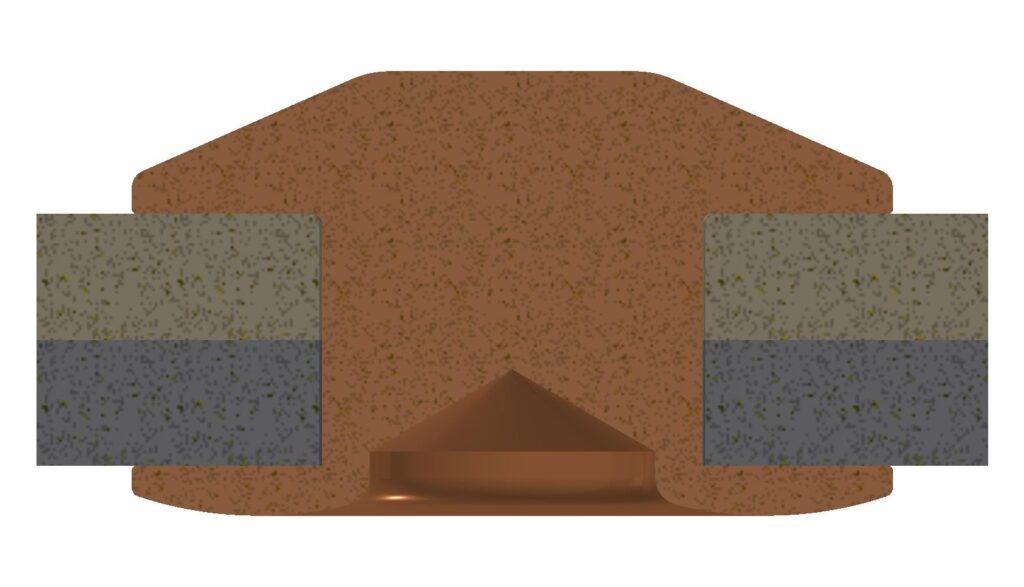

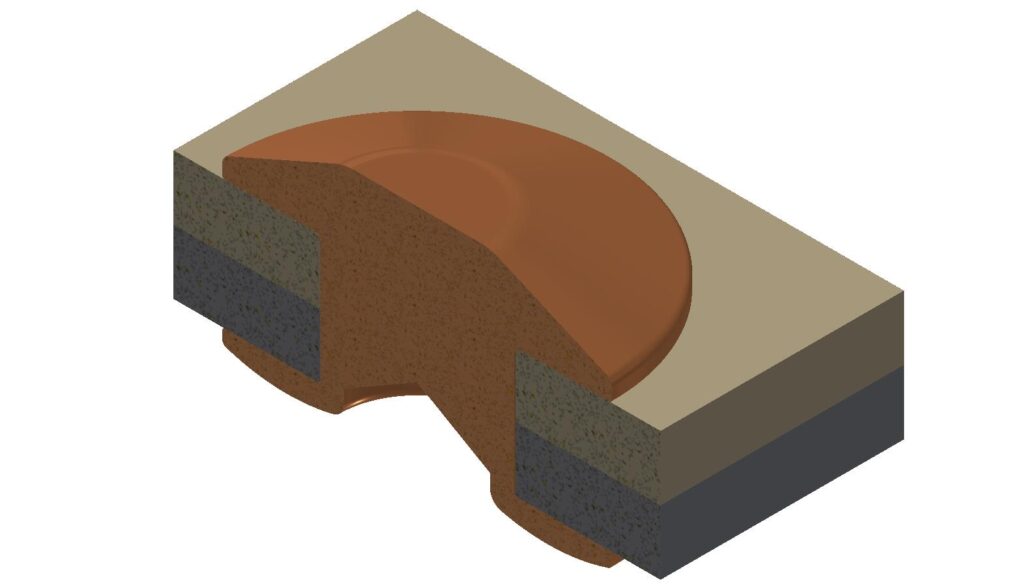

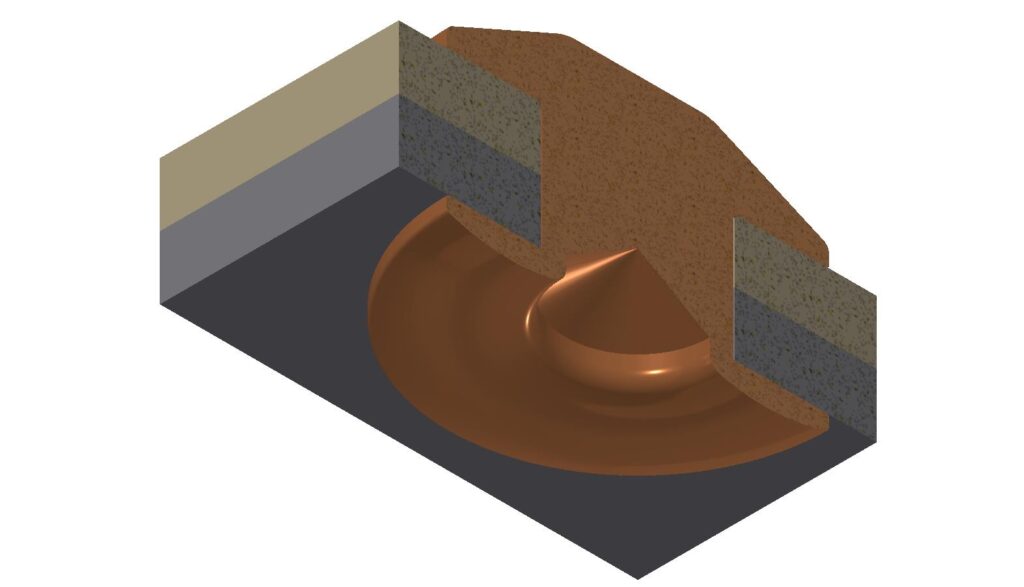

Hollow rivets are used for fastening (caulking) metal plates or molds. They are shaped like a single-header, consisting of a shaft (body part) and a head. To create a Hollow rivet, first a hole is made into the overlapped material. Then it gets inserted until finally the end of the protruding shaft gets punched to build the head. The form of the head can be made round or flat (other types possible). To achieve these forms, we do not use cutting processes on the wire material, but FINECS’ Cold Heading Technology, thus offering best quality and economic solutions.

Our hollow rivets are also used for positive and negative terminals of in-vehicle secondary battery terminals and more.

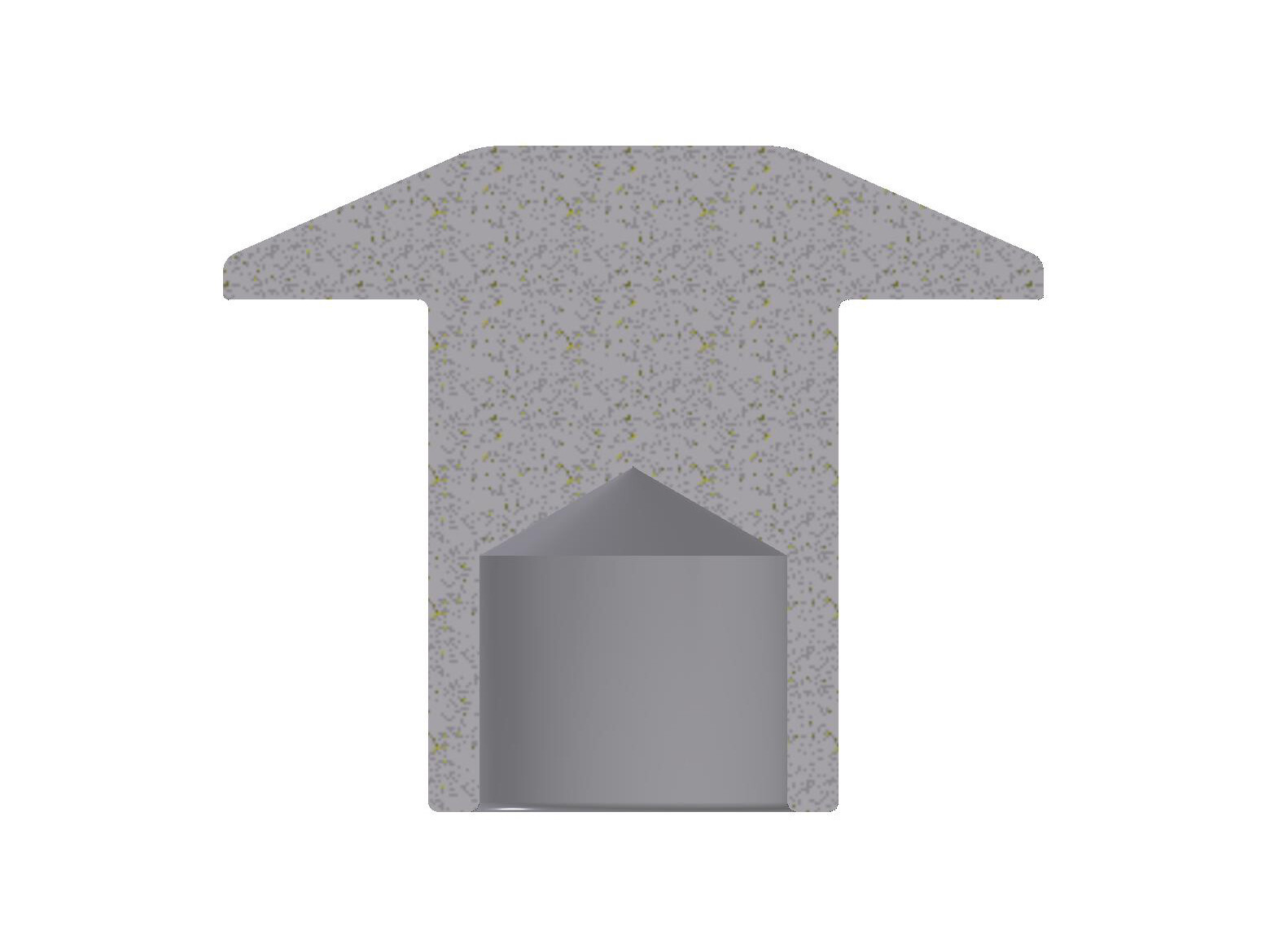

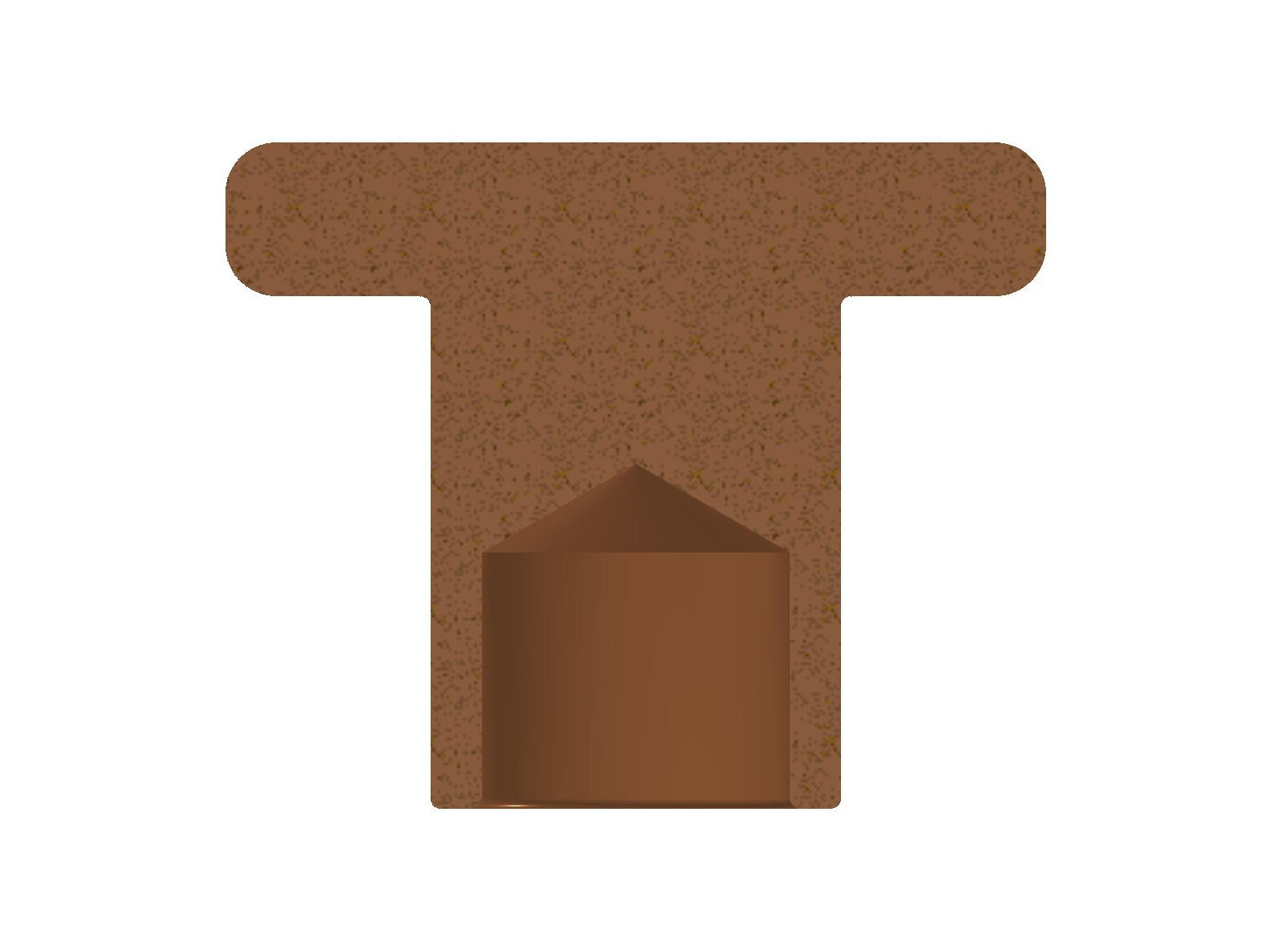

Hollow rivet dimensions

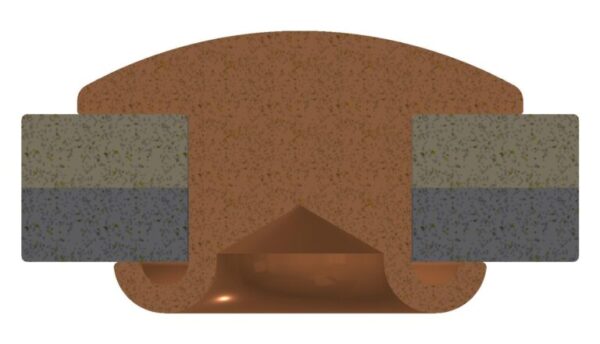

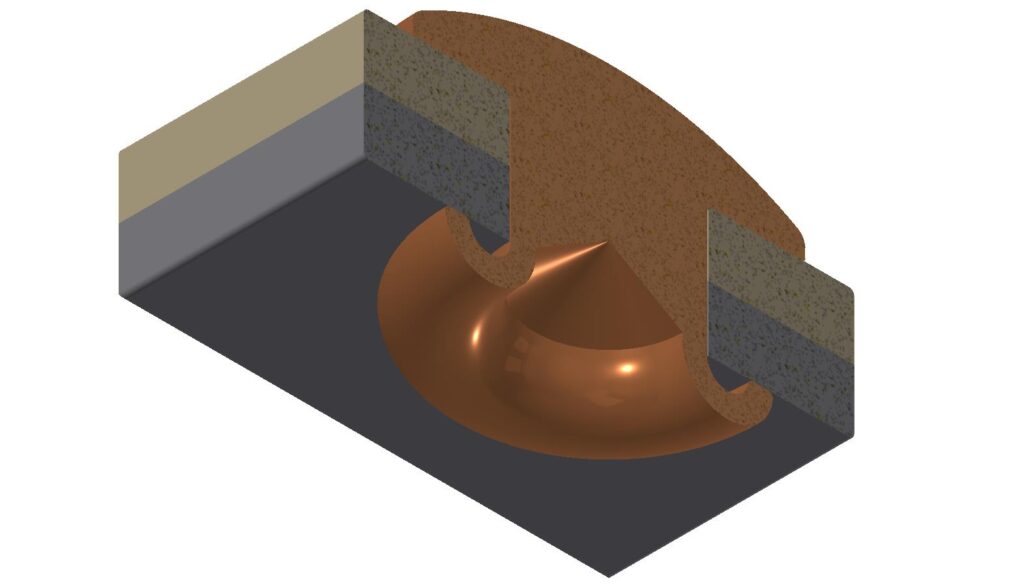

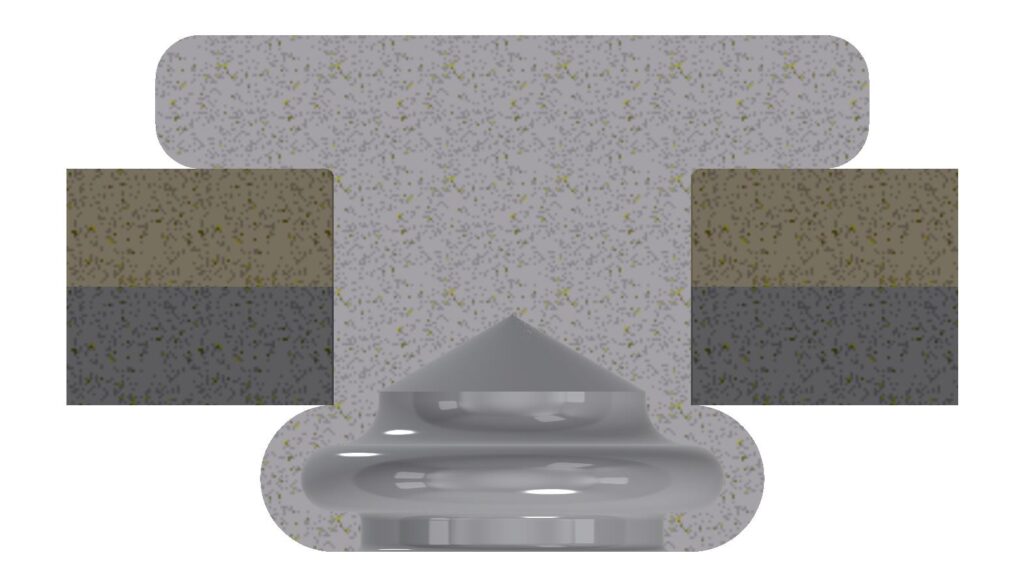

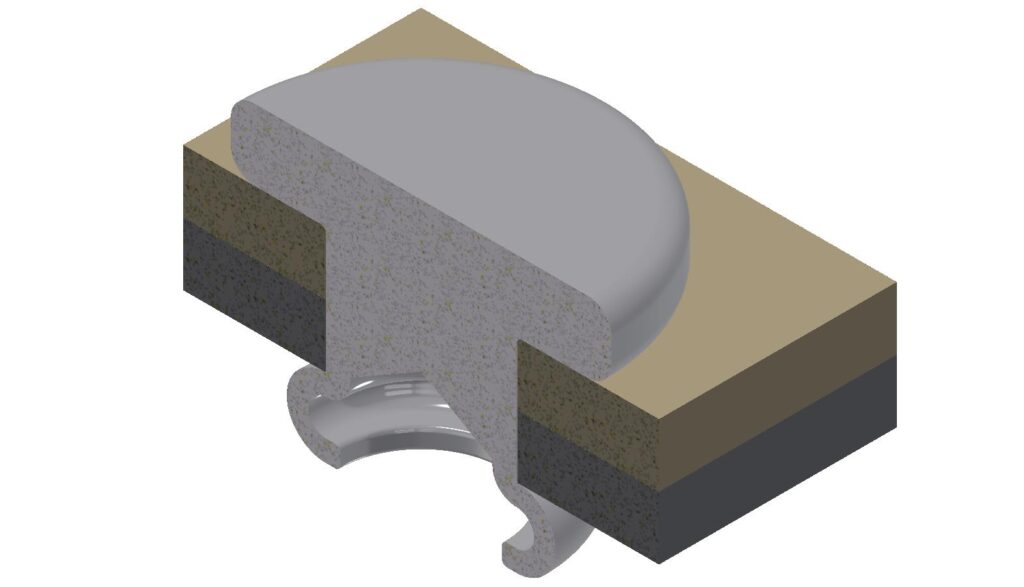

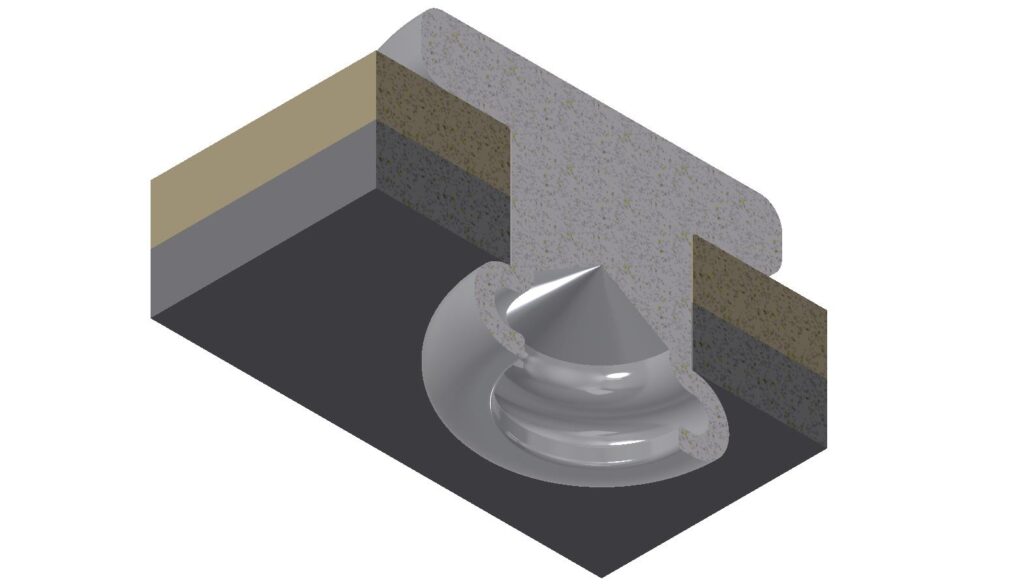

Example of hollow riveting

| example① |  |  |  |

| example② |  |  |  |

| example③ |  |  |  |

Q&A

Q:What kind of Hollow rivets do you offer?

A:We produce hollow rivets or micro rivets (header pins).

Q:About forms and crimping methods.

A:We offer the adequate solution according to your needs.

Q:What about occurrence of burrs?

A:Our special Cold Heading Technology makes it possible to produce with minimum burr occurrence.

Q:What is the MOQ for Hollow rivets?

A:We offer samples for prototyping from 10K up to mass production quantities of several 100M per month.

- * Specifications, materials, and other details are available upon request.