- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

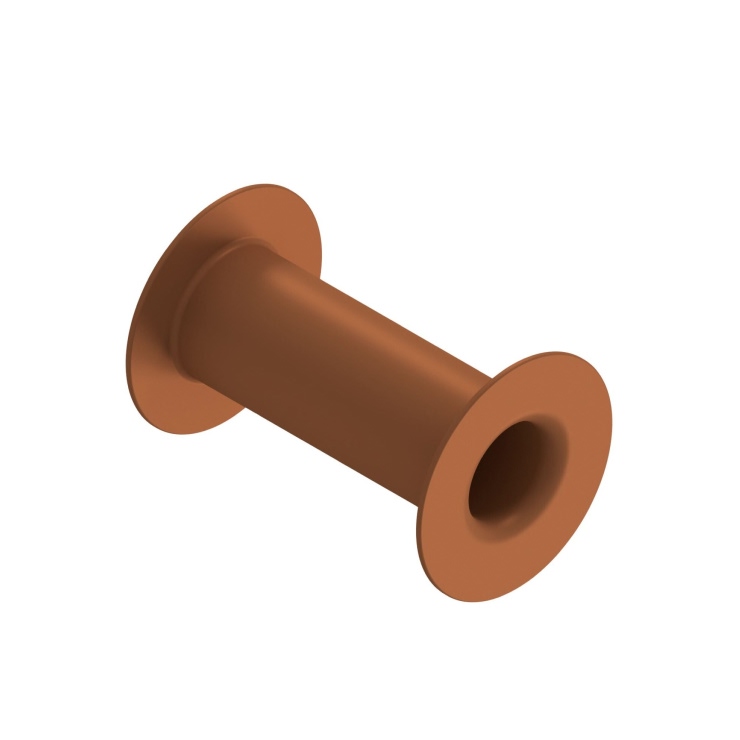

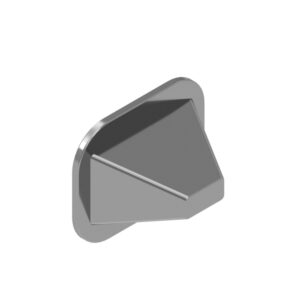

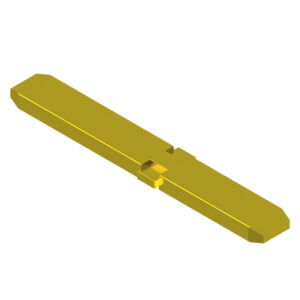

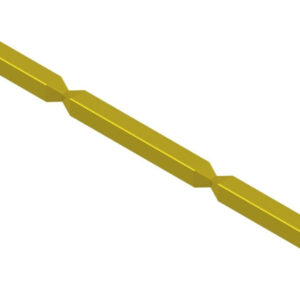

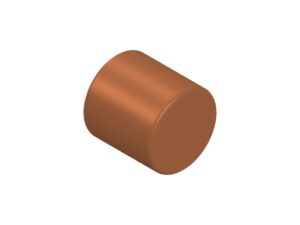

Rivet (Pin holder, Terminal holder)

FINECS Rivet Terminals are formed into a pipe shape using our proprietary heading technology developed over years of expertise. Our in-house designed and manufactured machines ensure highly accurate production. Unlike conventional drilling methods that require time and effort, our heading technology significantly increases processing speed per product, enabling cost reduction.

Request a quote or prototype| Material | Phosphorus-deoxidized copper |

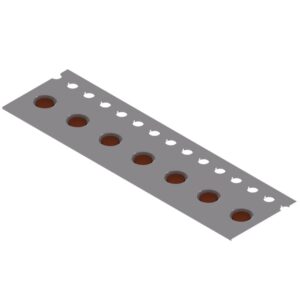

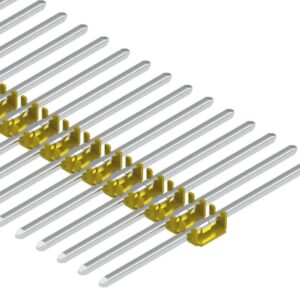

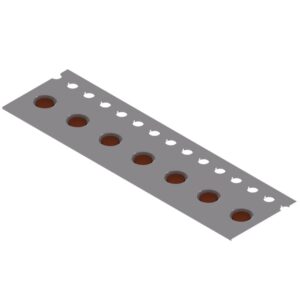

Examples of Rivet Terminal (Pin Holder) usage

The Rivet Terminal is used to connect Press-fit Pins and terminal pins to boards that cannot be drilled. (The rivet stands on the board and functions like an “alternative” hole.)

Rivet Terminals are used for IGBT modules and substrates for power semiconductors such as SiC modules.

Examples of adoption of power semiconductors such as IGBT / SiC modules

Power semiconductors such as IGBT / SiC modules are used in various fields such as inverters for HEVs / EVs and trains, UPS (uninterruptible power supply), and home appliances (air conditioners, etc.).

What is a Rivet terminal (pin holder)?

The Rivet terminal (pin holder) is a tubular terminal to support the pin that’s inserted into it. Rivet terminals (pin holders) are made by crimping wire rods into a tubular shape.

* Depending on the terminal’s shape, there may be patents existing. Therefore, a patent check is necessary.

* Plating options: Nickel plating, gold plating, no plating.

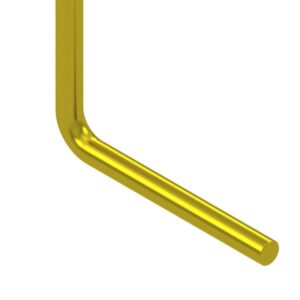

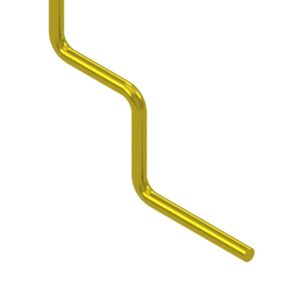

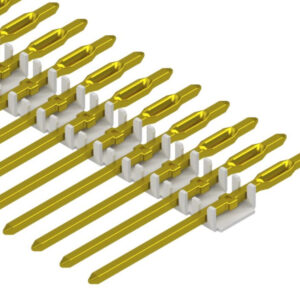

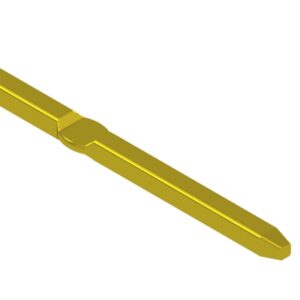

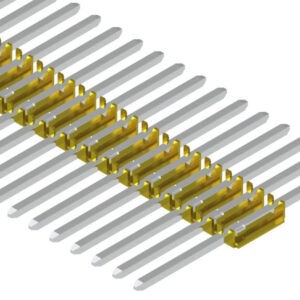

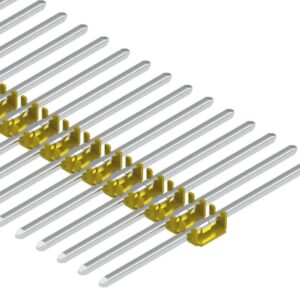

Rivet terminal (pin holder) and press-fit terminal

・When using our press-fit terminals, soldering with the mating board is not required.

・Our press-fit terminals can be processed from wire rods.The production of press-fit terminals made from wires reduces stamping die costs,material loss, and plating costs compared to the processing from a strip.

・The press-fit section becomes needle-eye type.

Rivet terminal (pin holder) and automatic insertion machine

We also sell an automatic insertion machine (FINESERT) that automatically inserts a pin into a Rivet Terminal that stands on a power semiconductor substrate such as an IGBT module.

When using the automatic insertion machine, the press-fit pins will be delivered as end-to-end pins.

Related Links

Products with the Same Shape

-

Embossed Taping (terminal pins & tiny components) -

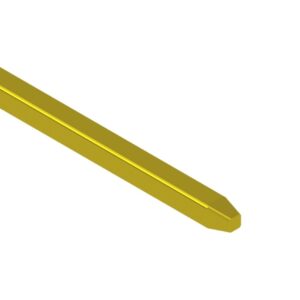

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

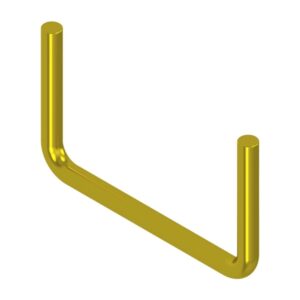

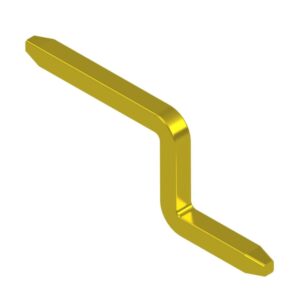

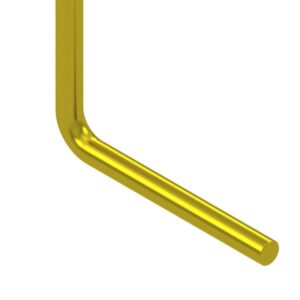

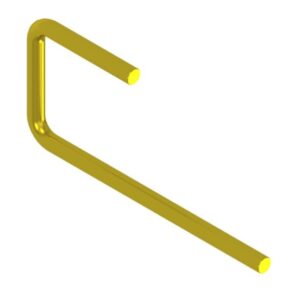

L-shaped pins (right angle) -

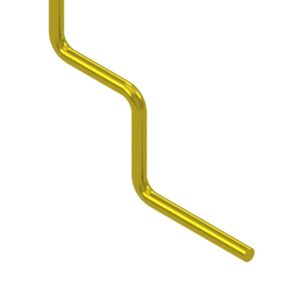

Double-step L-shaped pins -

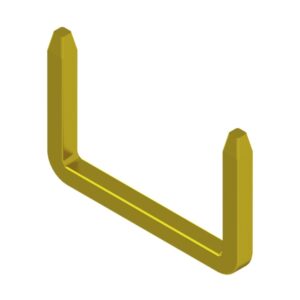

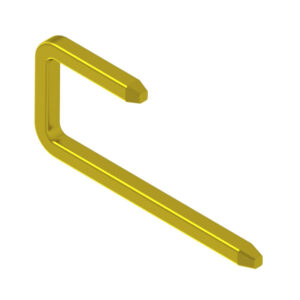

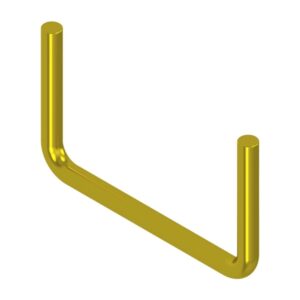

U-shaped pins -

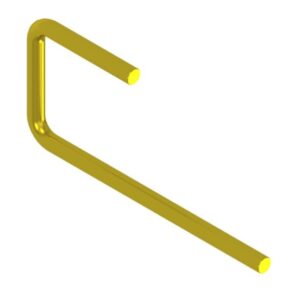

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

Mid-flanged straight pins with round chamfers -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (round type) -

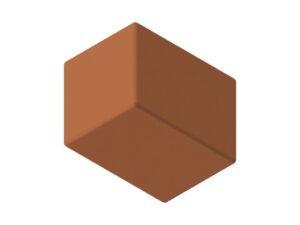

Block terminals (heat dissipation terminals and block pins) -

Connector Assembly with Wire Terminals -

Surface Treatment (Plating) -

Terminals with solder -

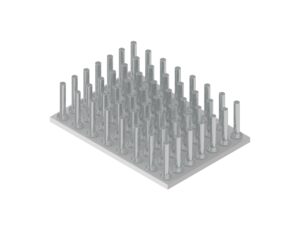

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

PGA Pins (Terminals for CPUs) -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay

Products with the Same Processing Method

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

Deep drawn pins / cups -

Pyramidal pins -

U-shaped pins Pyramidal pins -

Crank-shaped pins Pyramidal pins -

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

L-shaped pins (right angle) -

Double-step L-shaped pins -

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

Hollow Rivet -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay -

Electrode Terminals of Rechargeable Battery