Metal Parts Processing Business - From Vietnam with Japanese Manufacturing Technologies and Quality -

FINECS VIETNAM offers the metal working components used in automated machines, various facilities and dies, as well as metal pressing products used in automotive sensors and various electronic components.

If you wish to buy in Vietnam localized or have a intention to import the metallic machinery parts, precision parts, die and mold parts and cemented carbide, stamping parts etc. from Vietnam, Please feel free to contact us anytime.

Introduction

FINECS VIETNAM is a manufacturer of metal electro-discharge machining, metal-electrode machining, metal cutting and metal grinding machining at Vietnam-Singapore Industrial Park 1 in Binh Duong Province located 20 kilometers from Ho Chi Minh City.

Particularly we specialize in grinding, wire EDM and die sinking EDM and get high reputation from many customers.

A Japanese technician (a professional in machining practice-Class 1 of plane grinding technician) stays there to provide technical guidance and management.

In terms of quality, we are introducing three-dimensional measuring instruments and other measuring instruments to ensure stable quality.

Recently, as a manufacturer of electronic components, we have also started the press working for sensor parts used in automobile.

We believe it is our value and mission to maintain the same quality and sense of security as in Japan and to provide various parts for our customer with lower and affordable prices,

Regarding to the materials for our processing, we mainly use steel, also cemented carbide, aluminum and stainless steel.

For heat treatment, we have introduced a heat treatment furnande in house to shorten the lead time to our coustomer.

Customer can contact and purchase our commodities from Japan or Vietnam and if occuring claim about quality we will reply from Japan or Vietnam as a after-sales service to the customer.

FINECS Head Office in Toyama Japan promotes employment of Vietnamese technicians and trainees for many years in the field not only for metal parts processing but also for press working, forming and assembling electronic parts.

Through those practical training and experiences in manufacturing electronic components in Japan, we are focusing on developing human resources and enhancing manufacturing capabilities.

There are many Vietnamese staff in FINECS VIETNAM who learned Japanese language and culture through actual life and work in Japan. They are all key persons of engineer and manager who learned technologies and knowledges of manufacturing in Japanese way.

Strengths of FINECS VIETNAM

We always contribute to our customers through our three strengths and features.

- Quality and technology of the Japanese level

- We encourage our attitude to high-precision, high-quality engineering that is inherited from our FINECS Head Office Factory.

The Metallic Part Processing Service at FINECS Head Office Plant has approximately 50 years history, where we FINECS VIETNAM are inheriting DNA.

- We encourage our attitude to high-precision, high-quality engineering that is inherited from our FINECS Head Office Factory.

- We specialize in grinding and wire and electrode engraving electrical discharge machining for precision metal parts.

- We upgrade our facilities and pursue the skills of craftsmenship everyday.

- We will manufacture a whole set of die and mold. We also engage in the stamping press processing business for automotive components.

- Using metal parts processed in-house, we can manufacture and provide a complete set of die.

We also started metal press working business to manufacture terminals for sensor used in automobiles.

We operate this system under a quality control system that can accommodate mass production of automotive electronic components.

- Using metal parts processed in-house, we can manufacture and provide a complete set of die.

We are successfully responding and offering not only to customer in Vietnam and in Southeast Asia but also to Europe, America and Japanese who are seeking overseas procurement from Vietnam.

Outline of FINECS VIETNAM

| Company Name | FINECS VIETNAM CO., LTD. |

|---|---|

| Address | No.42, Street 6, Vietnam-Singapore Industrial Park, An Phu Ward, Thuan An City, Binh Duong Province, Vietnam |

| Industrial park | Vietnam-Singapore Industrial Park 1 (Binh Duong Province, Viet Nam) |

| Access | Around 20km north of center of Ho Chi Minh City. Around 1 hour by car from Ho Chi Minh City and 1 hour by car from Ho Chi Minh International Airport |

| Contact phone number (sales) | TEL:+84-274-3765-958 Japanese-speaking:+84-91-880-7330 Nishitani Yoshihiro |

| Contact E-mail (sales) | Vietnamese & English:px-trieu@finecs.co.jp Japanese:y-nishitani@finecs.co.jp |

| Web site | FINECS VIETNAM FACT LINK |

| Description of Businesses | Machine parts processing, die and mold parts processing, precision metal processing, metal (electronic parts) stamping press processing, die manufacturing |

| Site area | 18,000 m2 (factory area 4700 m2) |

| Number of employees | 3 Japanese engineers 98 Vietnamese staff members 17 employees experienced in Japan |

| Major customers (Japan) | Sunseiki Co., Ltd. Wisma International, Inc. FINECS Co., Ltd. |

| Major customers (Vietnam) | Fujikura Panasonic YKK Equipment, automated machinery, and die manufacturers Press working and mold processing manufacturers Healthcare, Semiconductor Equipment manufacturers Apparel manufacturing equipment manufacturers |

-> Detailed contact information can be found here (Jump to Contact below)

Introduction of FINECS VIETNAM Plant

List of Major Machine Tools and Facilities

All machining facilities are manufactured in Japan and is upgraded new with best condition for metalworking to achieve Japanese quality.

| Machine name | Machine model | Manufacturer | Unit number | Year of manufacture | Specifications | Environment | |

|---|---|---|---|---|---|---|---|

| Vertical Machining Center | V55 | Makino Millinx-g Machine | 3 | 2000 | 900×500×450 | 14,000mm/min | |

| Vertical Machining Center | V33 | Makino Milling Machine | 1 | 2004 | 750×635×250 20,000mm/min | 30,000mm/min | |

| Vertical Machining Center | F3 | Makino Milling Machine | 2 | 2017 | 650×500×450 20,000mm/min | 30,000mm/min | |

| Surface Grinder | PSG-64EX | Okamoto Machine Tool S/S | 1 | 2000 | 600×400 | Constant temperature environment suitable for precision machining | |

| Surface Grinder | ACC84CA | Okamoto Machine Tool S/S | 1 | 2014 | 800×400 | ||

| Surface Grinder | PFG500DXSL | Okamoto Machine Tool S/S | 1 | 2007 | 450×150 | ||

| Surface Grinder | PFG500DXPL | Okamoto Machine Tool S/S | 1 | 2001 | 450×170 | ||

| Surface Grinder | F-524ADP-R | Nicco | 1 | 2012 | 450×220 | ||

| Surface Grinder | F-515ADⅡPR | Nicco | 1 | 2012 | 450×170 | ||

| Surface Grinder | F-515ADⅡPR | Nicco | 1 | 2012 | 450×170 | ||

| Nc Surface Grinder | F-515DREAM-R | Nicco | 1 | 2012 | 450×170 | Grindstone width up to 0.1mm can be supported | |

| Wire Electric Discharging Machine | SL400Q | Sodick | 1 | 2014 | 400×300×250 | Wire diameter from φ0.1mm | |

| Wire Electric Discharging Machine | AL400G | Sodick | 1 | 2016 | 400×300×250 | ||

| Wire Electric Discharging Machine | AL600G | Sodick | 1 | 2016 | 600×400×350 | ||

| Wire Electric Discharging Machine | QA10 | MITSUBISHI | 1 | 2000 | 350×250×250 | ||

| Die -sinker Electric Discharge Machine | AG40L | Sodick | 1 | 2014 | 400×300×220 | High-precision built-in spindle specifications | |

| Die -sinker Electric Discharge Machine | SV12P | MITSUBISHI | 1 | 2020 | 900×650×350 | Compatible with fine hole machining up to φ0.2 | |

| Heat Treatment Furnace | NVF-50-OQ | Nakanippon Furnace Industry | 1 | 2012 | 250×250×400 | Vacuum Heat Treatment Furnace | |

| Heat Treatment Furnace | PQ-65/50/100 | IHI | 1 | 2017 | 650×500×1000 | ||

Processing Examples (Precision Parts Processing)

![[Cutting] Transport block, material: Aluminum](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-12.jpg)

![[Cutting] Mold for nylon, material: S50C](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-13.jpg)

![[Cutting] Lever, material: S50C](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-14.jpg)

![[Cutting/Grinding] Set-block, material: SKS3](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-15.jpg)

![[Grinding] Transport-plate, material: SKS3](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-16.jpg)

![[Grinding] Slider-block, material: SKS3](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-17.jpg)

![[Grinding/Wire EDM] Punching die, material: SKD11](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-18.jpg)

![[Grinding/Wire EDM] Equipment component, material: SKS3](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-19.jpg)

![[Grinding/Wire EDM] Bend-punch, material: SKD11](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-20.jpg)

![[Grinding/Wire EDM] Punching, material: SKD11](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-21.jpg)

![[Grinding/Wire EDM] Punching, material: SKD11](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-22.jpg)

![[Press die-type]](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-23.jpg)

Handling materilas

| Steel products | SS400,S45C,S50C, SKS,SKD,SKH, etc. |

|---|---|

| Aluminum material | A5052,A6061, etc. |

| Stainless steel material | SUS304, SUS440C, etc. |

| Other | Cemented carbide, resin material (MC nylon), Copper, brass, etc. |

Heat and surface treatment

- We have a vacuum heat treatment furnace (manufactured by Nakanihon Furnace Kogyo, IHI) that accommodates various steel, stainless steel and Inconel materials.

- Surface treatment (electroless nickel, alumite, black dyeing, etc.)

Although we outsource surface treatment (Japanese companies), there is no significant difference from Japan in term of quality.

Applicable machining accuracy

Cutting ±0.03mm, grinding ±0.002mm, wire EDM ±0.003mm, die sinking EDM ±0.005mm

We install the facilities made in Japan and are continually providing education and training for technicians to pursue stable quality with high precision.

Introduction of Die and Mold Manufacturing

FINECS VIETNAM now manufacturing press die and mold.

We design first then machine die and mold parts and assemble into whole set of die/mold in-house so that we can offer a one stop service for customer.

We have a successfull track record in sales of die and mold for electronic components, printer multifunction devices, jewelry-related parts, stationery-related parts, sports shoes and healthcare-related parts.

Currently, we mainly respond to customers in Vietnam but we hope to address the needs of customers who wish to procure overseas from Vietnam.

As we sincerely try to offer our lower and affordable price with high quality Japan, please feel free to contact us anyway.

-> Detailed contact information can be found here (Jump to Contact below)

![[Press die-type]](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-23.jpg)

Introduction of Pressed products of metal terminal used for in-vehicle sensor

FINECS VIETNAM manufactures precision pressed product for metallic terminal used in automotive sensor in-house, where processing and reparing neccessoy dies under management system ISO9001: 2015.

In order to ensure quality that can withstand in-vehicle components we introduce Toyota's five major control boards and manage each item of safety, quality, cost, production and human resources.

We set target values and promote visualization and improve process every day. We also commit to manufacturing with stable quality through anomalous assessing and 4M changes for QC.

We pursue stable quality in our own processes and strive to make customer feel that our products are affordable with good quality and valuable price.

In production line, we are promoting scientific manufacturing based on numerical calculations by introducing the core production information SAP system.

In future, we extend our business to manufacture precision press products, precision plastic mold products and to assembling component as well as manufacturing precision metal parts, dies and jigs.

Please feel free to contact us if you have any inquiry or plans to purchase the precise machined parts for automotive, electronics, medical and health care products in Vietnam or from other countries.

Quality Control System of FINECS VIETNAM

We aim to manufacture products of Japanese quality and Japanese accuracy.

- We guarantee the quality of metal precision machined parts and dies, etc to use ultra-precise three-dimensional measuring instruments and other measuring instruments depending on the situation.

- Through the training local employees, we conduct 100% in-process inspection and final inspection of all products in accordance with ISO9001 and assure our quality under control system comparable to that in Japan.

- In 2019, we obtained ISO 9001: 2015 certification. (The manufacturing of electronic components only.)

List of Measuring Instruments

| Instrument name | Instrument model | Manufacturer | Unit number | Year of munufacture |

|---|---|---|---|---|

| Measuring microscope | MF SERIES | MITUTOYO | 1 | 2012 |

| Measuring microscope | MM-800/L | NIKON | 1 | 2014 |

| Three-dimensional measuring machine | CRYSTA APEX S544 | MITUTOYO | 1 | 2013 |

| Three-dimensional measuring machine | XYZAX FUSION NEX | TOKYO SEIMITSU | 1 | 2017 |

Quality Control System

We are striving to improve our quality of metal parts processing business every day.

Currently, we are trying to achieve non-conforming products leakage "0" to the next process through self inspections and in-process inspections in each process.

As major approaches by the working staff in our manufacturing floor

- In order to prevent processing leakage, staff certainly checks to record on the drawing that he finished process.

- Staff measures and writes the finished dimensions on the drawing for himself. (It will give a rise to the staff attention to dimensional tolerance)

- Education and training for staff to improve knowledge and technology (deepen knowledge and integrate with technology through study meetings)

We are working to achieve the goal of "0" non-conforming product passing, however if a defective product will be found after delivery please inform your claim to our sales team of FINECS VIETNAM or FINECS JAPAN, they check the defective and reply in soonest possible.

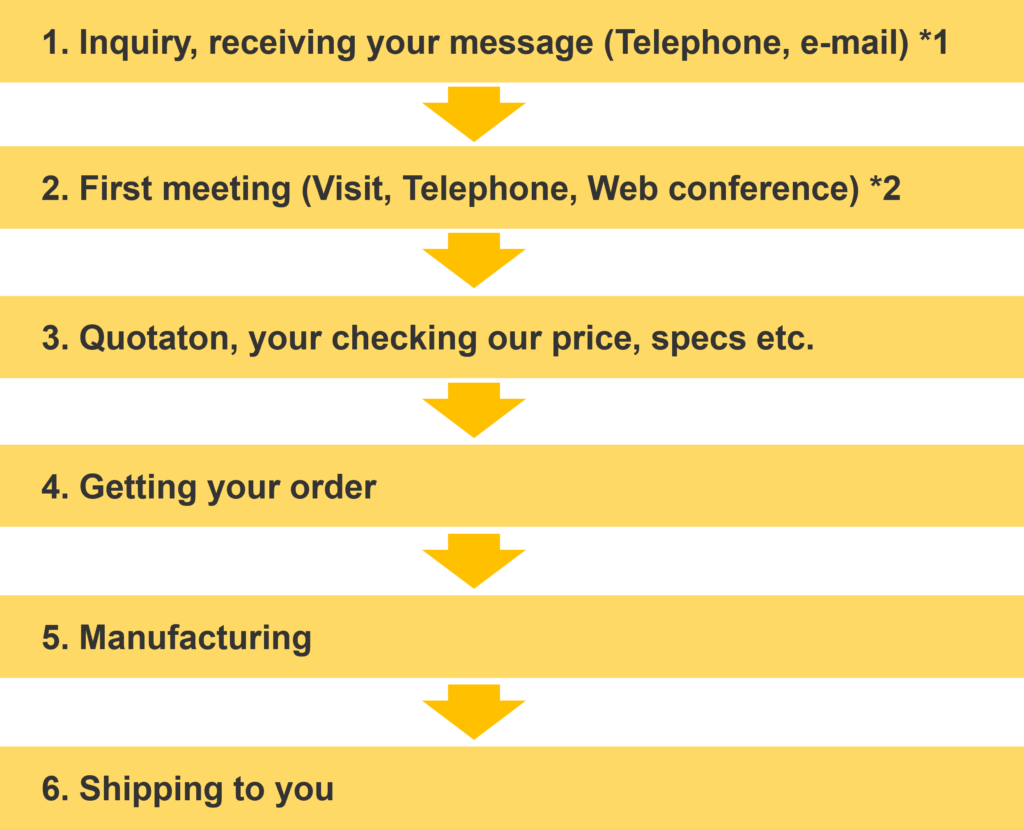

Service Flow

Please see our service flow.

*1. Contact

In addition, customers who wish to procure our service from Viet Nam, Asia, Europe, the USA, Oceania and other countries please feel free to contact directly FINECS VIETNAM by telephone or e-mail.

Customers in Japan please feel free to contact FINECS Head Office Toyama (Japan) or FINECS VIETNAM and FINECS VIETNAM reply soon.

-> Detailed contact information can be found here (Jump to Contact below)

*2. About WEB conference

We can do web conference and online meeting to transmit Microsoft Teams or Apple FaceTime. Other systems will be transmitted by the customer and we can handle.

Delivery date

We usually ship our product by air freight, which will take 2-3 weeks to your destination. If you like by sea freight, which 3-4 weeks to your destination. Details as per destination and our quotation.

To customers who wish to procure our service from Vietnam, we always try to work and ship our product as soon as possible.

Transaction currency

Customers order from Japan: JPY

Customers order in Vietnam: VDN, USD

Customers order from Asia, Europe and the USA: USD

We will respond your procurement in Vietnam and from overseas.

Payment term

We would appreciate your payment by the end of next month after the month of delivery to you.

Participate Exhibition

As we every year actively participate in exhibition Vietnam such as MTA, METALEX etc., please feel free to visit our booth and ask anything any time.

【MTA VIETNAM 2019 2019.07.02-05】

Exhibition sample product

![[Precision press die punch/cemented carbide machining sample]](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-34.jpg)

![[Precision Machine Parts Sample]](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-35.jpg)

![[Precision press die parts sample]](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-36.jpg)

![[Precision Machine Parts Sample]](https://www.finecs.co.jp/en/wp-content/uploads/sites/2/2023/02/vietnam-en-37.jpg)

Customer feedback

We would like to introduce some comments from our customers. Please let us share with your various and valuable opinions with us also.

It was a dealing in automotive parts that we asked, but we were feeling enjoyment.

At first we worried about overseas procurement from Vietnam in terms of quality and after-delivery service, but actually in the event of our harder delivery time and our changing sepcs, they helped us quickly. As you know, automotive parts, demand quiality level is very high so that we like to continue to ask them to make our parts.

In-Car Industry Purchasing Manager

Thank you for your polite response.

We have revised design and drawing many times, but you understood us and responded every time, we thank you so much.

General Manager of Piping Industry Plant

We are satisfied with your high-quality, high-precision machine parts.

Even though we did not have a drawing and asked delivery so short, you measured our exsisting parts and drew by yourself. Of course the parts you made for us are so nice. We really satisfied with your quality and accuracy amazing. Very grateful to FINECS VIETNAM!

Person in charge of technology in the healthcare industry

The quality was stable even we ordered press die parts by material carbide steel !

I asked for press die parts, and the quality is stable even in carbide processing. FINECS is very helpful in delivering Japanese quality with lower than procurement from Japan. And they surely served quick response to our expectation about after sales service too ! I am looking forward to working with them in future too.

General Manager of Electronics Industry Plant

We found a nice supplier because we can change into Vietnamese localization from European procurement. Very satisfied.

We have been buying dies from Italy for many years and felt it is serious to face long lead time to Vietnam from Europe with high price. To know you of FINECS VIETNAM at the exhibition Ho Chi Minh city, we asked you to make our dies right away. Technique is splended. It is best for us to buy dies to shorten time with lower prices in Vietnam. It is really nice to meet FINECS VIETNAM.

Purchasing representative of jewelry industry

The factory is clean and secure. Improvement of working environment convinces us it is a Japanese way.

You have been very helpful in dealing with Japanese quality for us in Vietnam. We have toured your clean and beautiful plant, where management was done same way in Japan. And we were very relieved to know that you are introducing the latest equipment and focussing the working environment for the pursuit of high precision. Thank you so much for your continuous support.

Purchasing representative of decorative industry

Please feel free to contact us.

Please feel free to contact us if you considering procurement in Vietnam or procurement oversea from Vietnam for metalworking parts, various molds, jigs and precision pressed parts .

Consultation/Quotation Contact

FINECS VIETNAM (Vietnam Plant/Binh Duong Province)

Sales Manager: Ms. Hien, Plant/Sales Director: Mr. Nishitani

TEL:+84-274-3765-958

Mobile(Japanese: Mr. Nishitani) :+84-91-880-7330 (Monday-Saturday 8:00-17:00)

FAX:+84-274-3765-967

E-Mail(English&Vietnamese):phm-hien@finecs.co.jp

E-Mail(Japanese):y-nishitani@finecs.co.jp

FINECS Co., Ltd. (Head Office/Toyama, Japan)

General Manager, Machinery Engineering Department, Mr. Tamo

TEL :076-462-0082 (Monday to Friday 8:00 to 17:00)

FAX :076-464-1800

E-Mail (Japanese): n-tamo@finecs.co.jp

After receiving your inquiry, we will pass them to our Vietnam plant immediately.