INDUSTRIAL MACHINERY

In the industrial equipment sector, where long-term stable operation and high reliability are essential, FINECS components deliver outstanding performance.

Our terminals and pin parts—used in machine tools, communication devices, power supplies, and control panels—maintain reliable connectivity and conductivity even under harsh conditions such as vibration, heat, and humidity.

By integrating cold forging, precision pressing, and plating technologies, we achieve an exceptional balance of structural strength and dimensional accuracy. This advanced capability has earned the trust of leading equipment and control system manufacturers.

industrial- Product List

-

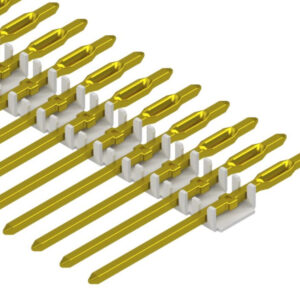

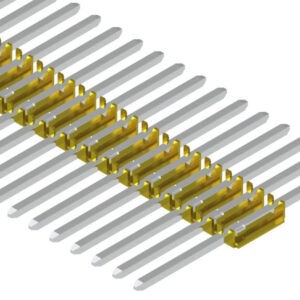

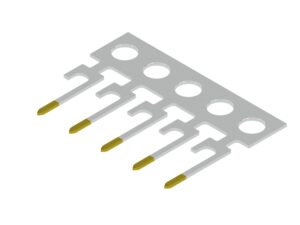

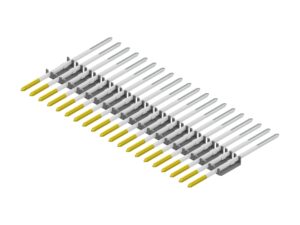

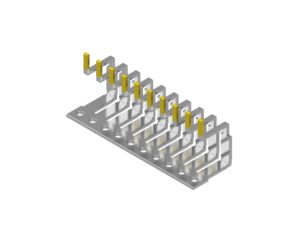

Press-fit bandolier terminals

Ensures a consistent insertion orientation for terminals

-

Deep drawn pins / cups

Components featuring cup-shaped terminals or pins

-

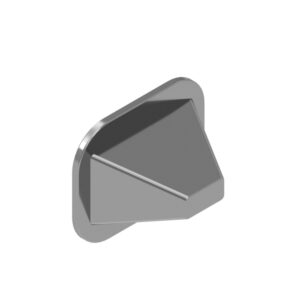

Pyramidal pins

Processed by cold forging into a pyramidal shape

-

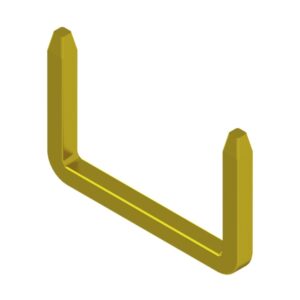

U-shaped pins Pyramidal pins

Used as jumper wires

-

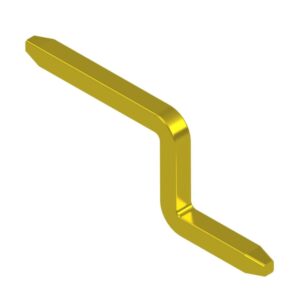

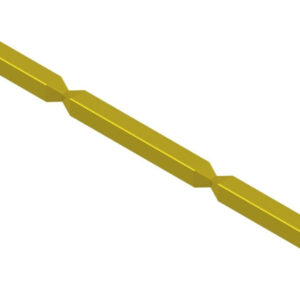

Crank-shaped pins Pyramidal pins

Pyramidal tapers on both ends with a crank bend in the middle

-

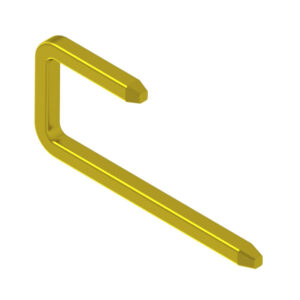

J-shaped square pins

Processed by cold forging into a shape resembling the number 7

-

L-shaped pins Pyramidal pins and cross-shaped cross sections

Flattening combined with a right-angle bend

-

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections

Connector and transformer terminals

-

„ear-crush“ flat square with pyramid taper

Flattened section that retains part of the original wire diameter.

-

Swaged straight pins Pyramidal pins and cross-shaped cross sections

Pin with one end rounded

-

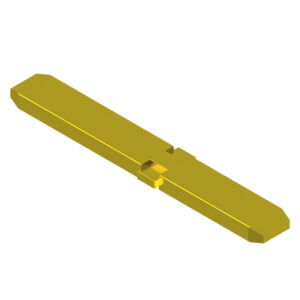

Straight pins Pyramidal pins and cross-shaped cross sections

A flattened middle section featuring diagonal protrusions

-

Partially pinched straight pins Pyramidal pins

Flattened in the middle while retaining part of the original wire diameter

-

Partially flattened straight pins Pyramidal pins

Pyramidal taper with a flattened section in the middle

-

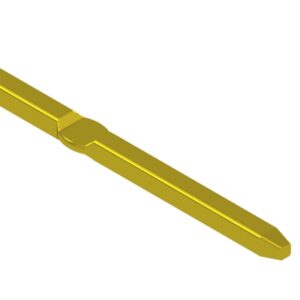

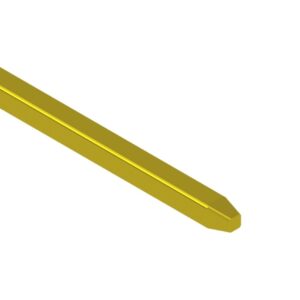

Straight pins Pyramidal pins

Square wire with pyramidal tapers on both ends

-

Mid-flanged straight pins with conical tapers

Conical tapers on both ends with a collar formed in the middle

-

Straight pins with conical tapers and cross-shaped cross sections

Flattened in the middle with protrusions extending in a cross direction

-

Partially pinched straight pins with conical tapers

Flattened in the middle while retaining part of the original wire diameter

-

Partially flattened straight pins with conical tapers

Cone-shaped taper with a flattened section in the middle

-

Straight pins with 4-side tapers from round wires

Round wire with four tapered surfaces applied to both ends

-

Straight pins with conical tapers from round wires

A component made from round wire featuring conical tapers on both ends

-

Partially flattened straight pins with round chamfers

A part with barrel-chamfered ends and a flat crimp in the middle

-

Partially pinched straight pins with round chamfers

A part with barrel-chamfered ends and a flattened crimp in the middle

-

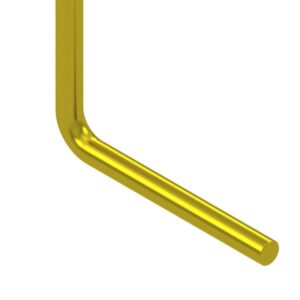

L-shaped pins (right angle)

A part with a right-angle bend in the middle

-

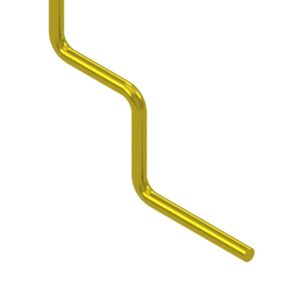

Double-step L-shaped pins

A part with two right-angle bends in the middle

-

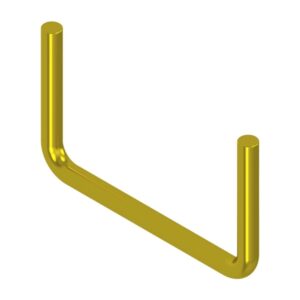

U-shaped pins

A part with a U-shaped bend in the middle

-

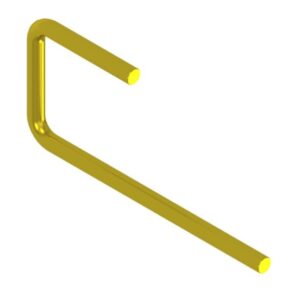

J-shaped round pins

A part with two or more bends in the middle

-

Partially flattened L-shaped pins

A part with a right-angle bend and a flat crimp in the middle

-

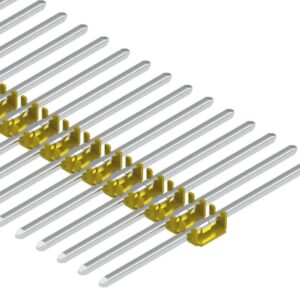

High-volume Pins

Single header pin with an exceptionally large flange

-

L-shaped pins Pyramidal pins

A part with tapered pyramidal ends and a right-angle bend in the middle

-

Mid-flanged straight pins Pyramidal pins

A component with tapered pyramidal ends and a flange in the middle

-

Mid-flanged straight pins with round chamfers

Featuring barrel chamfering on both ends and a flange in the middle

-

Needle-eye square press-fit

Featuring a needle-eye shaped design.

-

Bandolier terminals / pins made from square or flat square wires

Ensures a consistent insertion direction for terminals

-

Bandolier terminals / pins made from round wires

Ensures a consistent insertion direction for terminals

-

Crank shaped pins

Featuring crank bends in the middle section

-

End-to-end pins / End-to-end terminals (press-fit type)

Continuous pins with press-fit terminal shapes

-

End-to-end pins / End-to-end terminals (square type)

Delivered on reels without cutting each piece, keeping them connected

-

End-to-end pins / End-to-end terminals (round type)

Delivered on reels without cutting each piece, keeping them connected

-

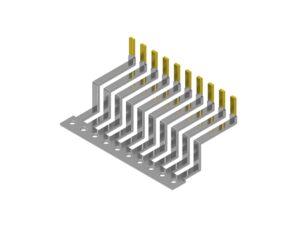

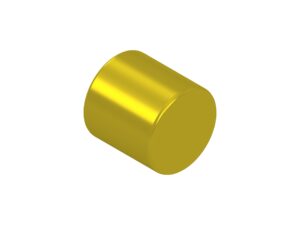

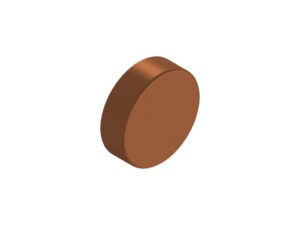

Block terminals (heat dissipation terminals and block pins)

Cylindrical or rectangular terminals and pins

-

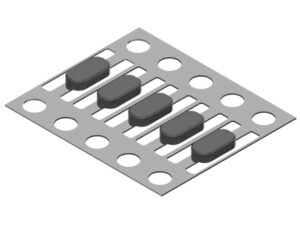

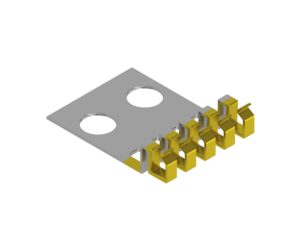

Connector Assembly with Wire Terminals

Insert bandolier terminals into the connector housing in bulk

-

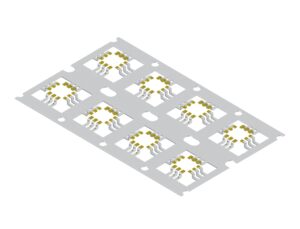

Gold-plated parts

A product offering stable corrosion resistance, excellent electrical conductivity, and superior solderability.

-

Partial Au plating

Helps reduce gold usage

-

Partially soft-gold plated parts・Hoop plating

Soft gold plating with 99.99% purity

-

Silver plating (Ag plating) / Silver Hoop plating / press & plating

It offers excellent electrical and thermal conductivity

-

Surface Treatment (Plating)

Offers excellent solderability, corrosion resistance, and electrical conductivity

-

Plated bandolier pins

Continuous plating of pins embedded in a carrier produced by progressive press processing

-

Outer lead frame plating

Used as crimp terminals and connector terminals for various electronic components.

-

Terminals with solder

A product with solder bonded at the center of the header surface

-

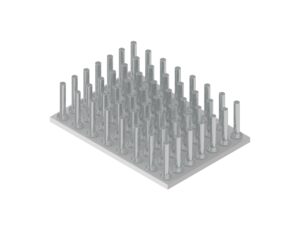

Heat radiating pins for heat sinks

Designed for applications like heat sinks to disperse and release heat effectively.

-

Rivet (Pin holder, Terminal holder)

Allows placement at any position on the board without drilling holes.

-

Hollow Rivet

This component is used for fastening (crimping) metal plates and profiles.

-

Connector terminals / Connector pins

Various Shapes Achieved Through Our Proprietary Cold Forging and Header Processing Technologies

-

Lead pins / Diode terminals

An electronic component with rectifying properties

-

Jumper pins

Used on substrates

-

Press-fit terminals (from wire)

Eliminates the soldering process and contributes to reducing environmental impact.

-

Substrate terminals / Post pins

Compatible with a wide range of boards, such as ceramic and alumina types.

-

Conductive terminals

Used in diodes, LEDs, semiconductors, and CCFL cold cathode tubes

-

Kovar pins (electrode pins)

Cuts the edge angles and fracture surfaces using a proprietary method

-

Brazing filler metal cut pieces (gold, silver, copper, etc.)

Wire brazing alloys cut to specified lengths

-

Ultra-small pins, extra-fine pins, micro pins

Used for connecting semiconductor chips to package interposers

-

Plungers for Contact Probes

Eco-friendly because it does not generate chips due to cutting process.

-

Copper inlay

Enables thermal management to maintain electronic component performance and extend product lifespan.

-

Electrode Terminals of Rechargeable Battery

Positive and negative terminals for next-generation vehicles.

-

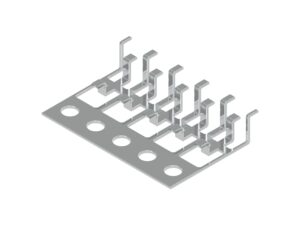

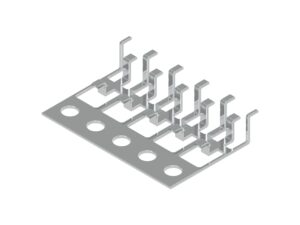

Power semiconductor terminals (press-working and surface treatment)

Manufactured through processes such as punching and bending.

-

Connector terminals (press-working and surface treatment)

Manufactured through processes such as punching and bending.

-

Diode terminals / connectors (press-working and surface treatment)

Manufactured through processes such as punching and bending.

-

Press-fit Terminals/Pins (press-working and surface treatment)

Enables cost reduction and lower environmental impact.

-

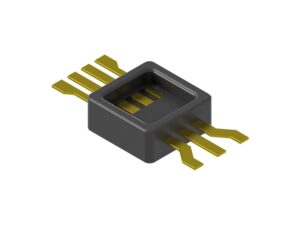

Sensor Assemblies with Pressed Terminals

In-house facilities and molds for integrated production