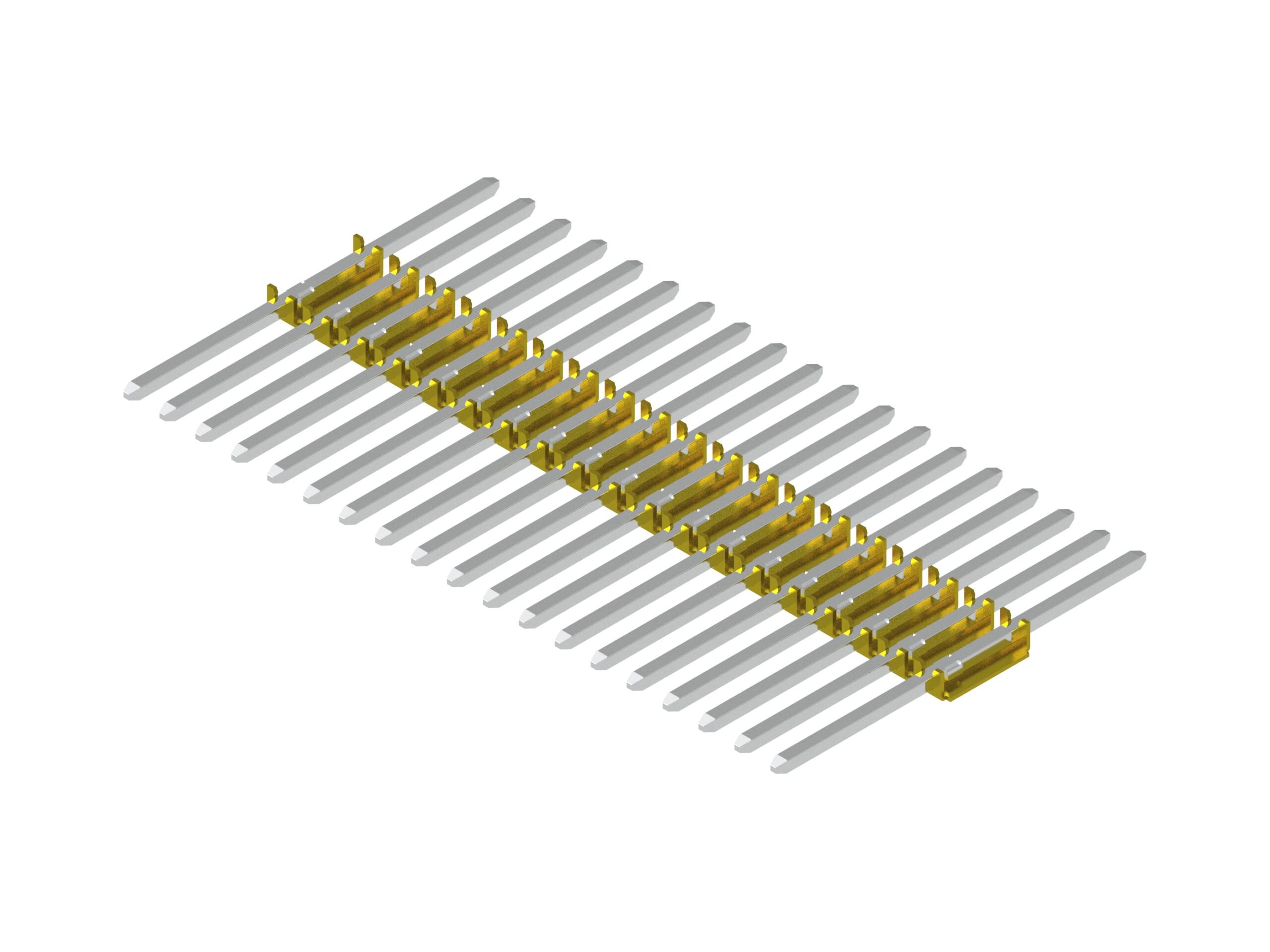

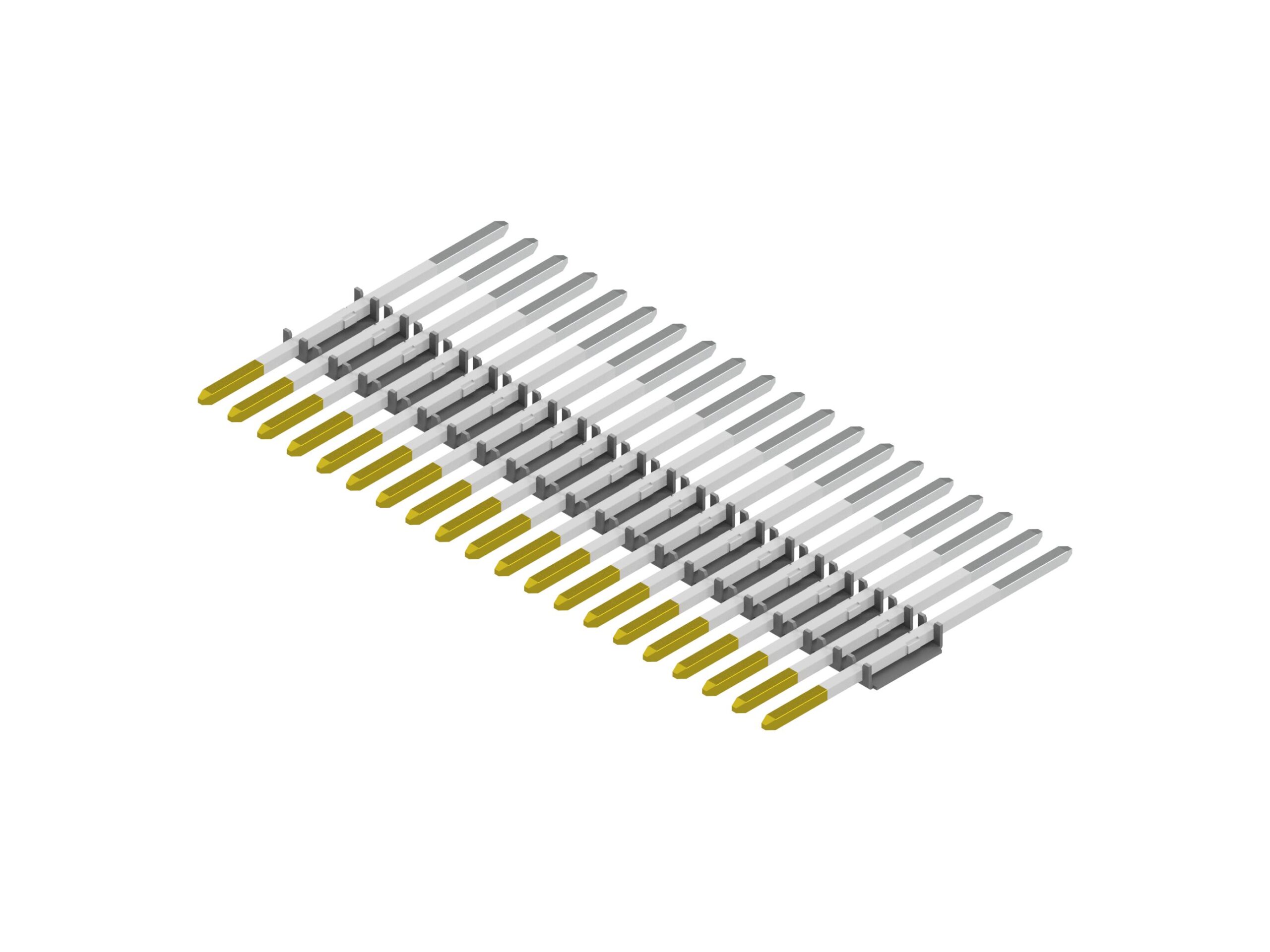

Bandolier terminals / pins made from square or flat square wires

In case standard specifications and dimensions of pins / terminals for bandoliers are requested, no initial equipment costs will occur. (Custom-designs may differ)

Sn reflow plating (pre-plating) specifications

Sn reflow plating (pre-plating) specifications One-side Au, Sn reflow partial plating (post-plating) specifications

One-side Au, Sn reflow partial plating (post-plating) specifications

Available sizes, shapes, etc.

Possible pitches: 2.0mm, 2.54mm, 3.0mm~

Please call us for diameter, length and other related specifications

Total length: As separately discussed

Material

Brass, phosphor bronze, or other by arrangement

Surface treatment

Partial gold plating, one-side tin reflow plating, overall tin plating

Main uses

Connector components for automotive or consumer applications, relay components and more

Product features

The terminals are directly planted on the band (carrier) and winded on reels afterwards. Various band dimensions are available, according to the pitch of each housing, thus increasing the number of pins that can be inserted all at once during your assembly processes, but also improving the tact time of the production line.

Furthermore, please have a look at the following 4 advantages of our bandoliers.

1. All pins have the same insertion direction

2. Bandolier with or without plating can be handled. It does not matter if you need pre-plating, post-plating or only partial plating, all types are available. Through partial plating it is possible to reduce material costs. We offer Au plating and more.

3. Compared to pressed terminals, a huge reduction of initial equipment costs can be achieved.

4. All 4 sides of the terminals can be plated.

Please have a look at the video below to get an impression of how bandolier pins are manufactured.

Q&Aコーナー(バンドリア端子・バンドリアピン)

Q:冷間鍛造(圧造加工)でどのような形状までバンド対応可能ですか?

A:各種形状での対応が可能です。詳細は、角線・平角線、プレスフィットの各コーナーにて適応形状をご提案中です。是非ご確認下さい。

Q:めっき対応は可能ですか?

A:先めっき線(Snリフロー)仕様、後めっき(Au部分めっき&Sn部分めっき)仕様でのご提案が可能です。

Q:可能な端子ピン線径、長さ、ピッチはどれくらいですか?

A:線径は□0.64mm、1.5×0.64mmを中心に、色々な長さに調整で対応可能です。

Q:数量はどれくらい生産できますか?

A:試作1万本~量産では数万本/月でも対応可能です。

Q:どのようなコストメリットがありますか?

A:線材圧造品はプレス品と比較して材料屑が出ない、ハウジングに圧入する際に数本まとめて同時に圧入でき、タクトアップができるという利点があります。

Q:バリ、ダレの発生はしますか?

A:線材の為端子の側面にバリやダレは出ません。先端のテーパ部のバリ、ダレの発生を極力抑えた加工実績で信頼を頂いております。

Q:プレス部品からの切り替えを検討したいが、プレスピンと比較して精度どれくらいですか?また、プレスピンと比較して金型費は安い?プレスピンと同等の形状は可能ですか?

A:精度はプレス品に劣りません。金型費は圧倒的に安く金型費が全くかからない場合もあります。詳しくは「条材プレス加工と線材圧造ヘッダー加工の比較のページ」にてご確認下さい。

Q:梱包仕様について

A:プラリールや一部輸出用などではダンボールリールでの出荷対応となります。

Q:コネクタ・スイッチ等までの一貫生産対応提案等も可能ですか?

A:バンドリア端子・バンドリアピンより組立てまでの一貫生産も対応可能です。

Applicable shapes of Bandolier terminals / pins made from square or flat square wires

Straight pins with pyramidal tapers

Partially flattened straight pins with pyramidal tapers

Partially pinched straight pins with pyramidal tapers

Straight pins with pyramidal tapers and cross-shaped cross sections

Mid-flanged straight pins with pyramidal tapers

Swaged straight pins with pyramidal tapers and cross-shaped cross sections

„ear-crush“ flat square with pyramid taper

- * For details, please also refer to "Highlighted Case Examples."

Generating less material waste than press-formed terminals, products of this type will contribute to environmental conservation. - * Specifications, materials, and other details are available upon request.