- search by shapes

- search by processing method

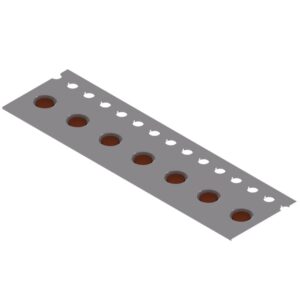

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

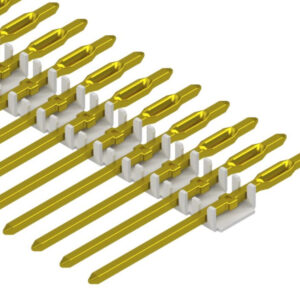

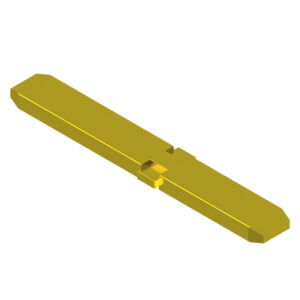

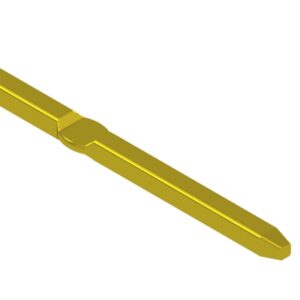

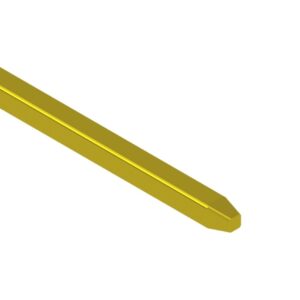

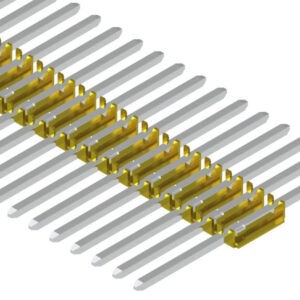

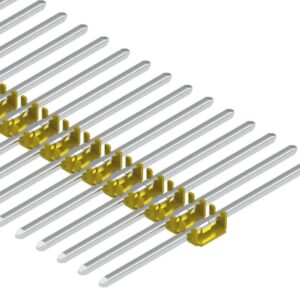

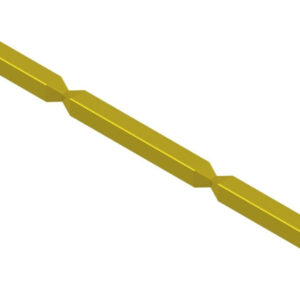

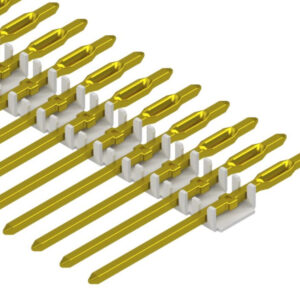

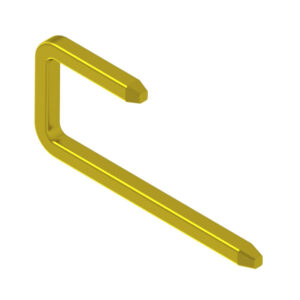

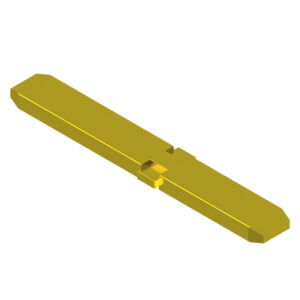

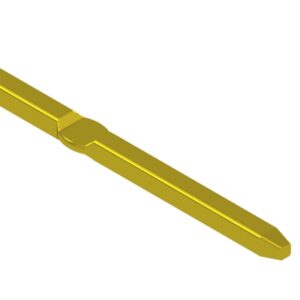

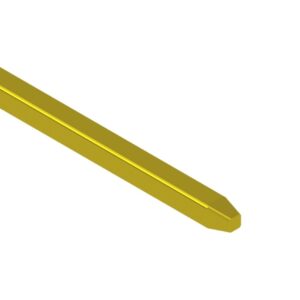

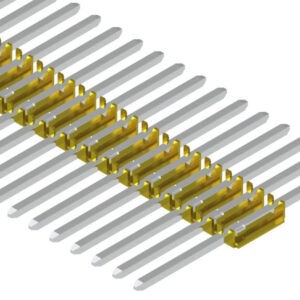

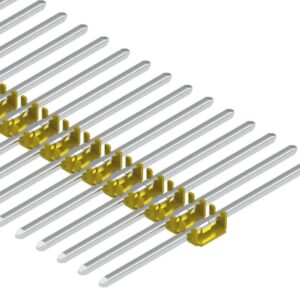

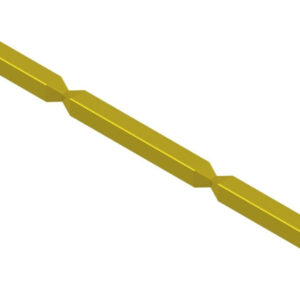

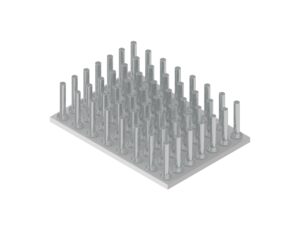

Block terminals (heat dissipation terminals and block pins)

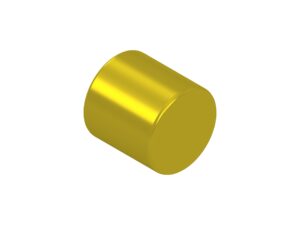

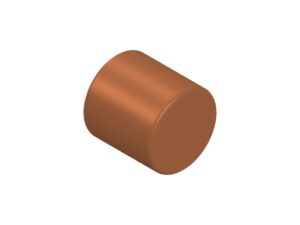

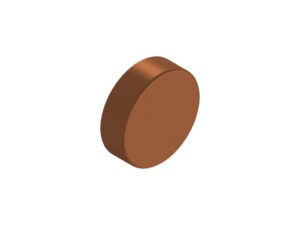

Various metal wires are cut, header-processed, and press-formed into block terminals such as heat dissipation terminals, block pins, and solid terminals in shapes like cylinders or quadrangular prisms. Cross-sectional options include round, square, rectangular, elliptical, and irregular forms. Compared to strip-based press processing, this method significantly reduces material waste and lowers initial die costs.

Request a quote or prototype| Reference standards | φ0.05mm~φ8mm、□0.2mm~□8mm |

| Shapes | Cylinders, square columns, etc. |

| Material | Copper metals, various copper alloys, brass, aluminum, precious metal alloys, etc |

Main applications

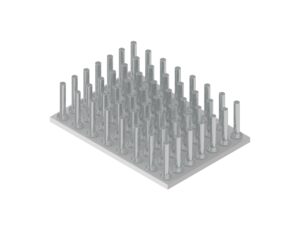

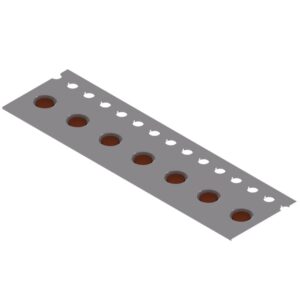

・Press-fitted into circuit boards for heat dissipation

・Attached to semiconductors and ICs for heat dissipation and heat removal

・Connection between boards

・Grounding of boards to chassis

What is Block terminal?

Block terminals (heat dissipation terminals and block pins) are cylindrical or prismatic terminals and pins made of copper or other materials. They are mainly used for heat dissipation applications such as circuit boards or as energization terminals for surface mounting.

Using a unique processing method that takes advantage of the merits of wire rod processing, we can reduce prices and realize high-precision products.

Plating processes such as Sn and Au, and taping processes for use with mounters are also available.

Benefits of Block Terminals

1. Significant Reduction in Mold Costs

Wire processing molds are smaller and more cost-effective compared to press molds.

2. Precision: Within 1° Perpendicularity and Over 95% Flatness

Achieves high accuracy in perpendicularity, flatness, and surface roughness.

3. Eco-Friendly and Cost-Efficient with Zero Material Waste

Unlike sheet metal punching, wire processing eliminates material waste entirely.

4. Embossed Packaging Available

We offer packaging solutions tailored to your application needs.

Related Links

Products with the Same Shape

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

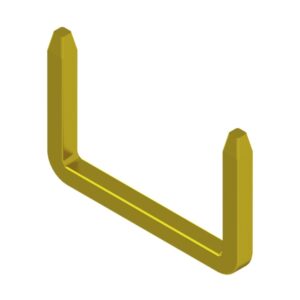

U-shaped pins Pyramidal pins -

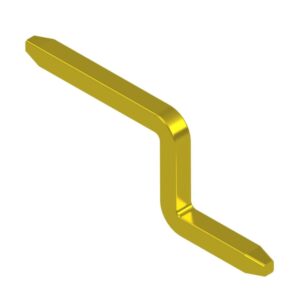

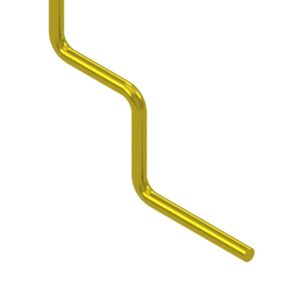

Crank-shaped pins Pyramidal pins -

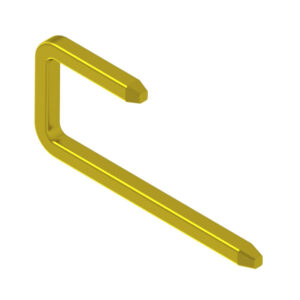

J-shaped square pins -

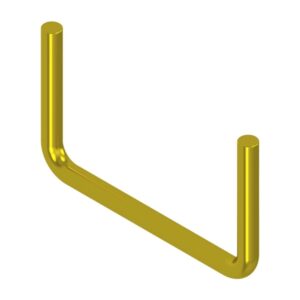

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

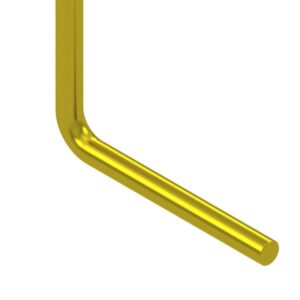

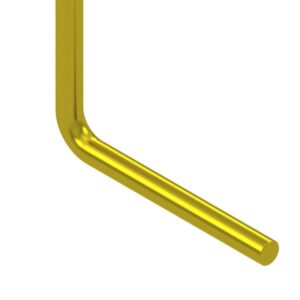

L-shaped pins (right angle) -

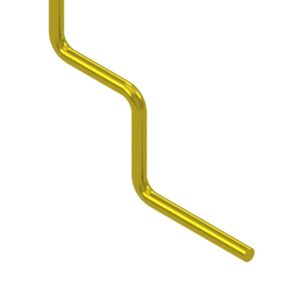

Double-step L-shaped pins -

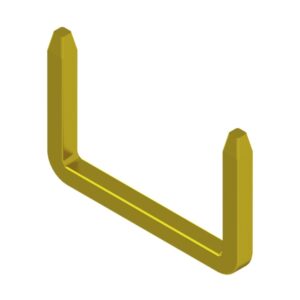

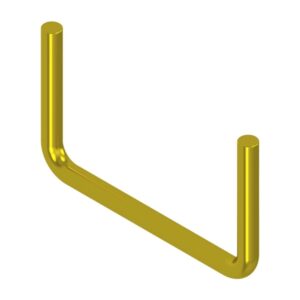

U-shaped pins -

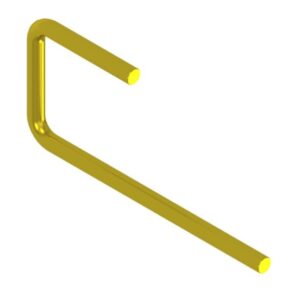

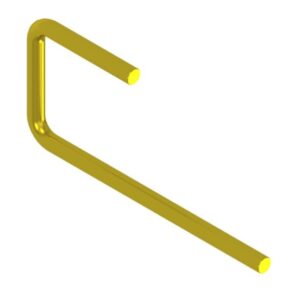

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

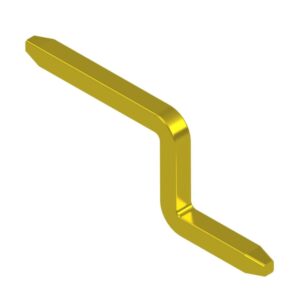

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Connector Assembly with Wire Terminals -

Surface Treatment (Plating) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay

Products with the Same Processing Method

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

Deep drawn pins / cups -

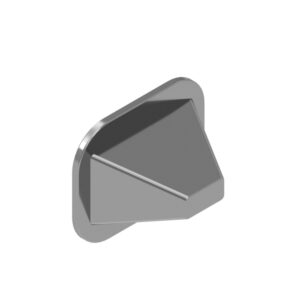

Pyramidal pins -

U-shaped pins Pyramidal pins -

Crank-shaped pins Pyramidal pins -

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

L-shaped pins (right angle) -

Double-step L-shaped pins -

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

Hollow Rivet -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay -

Electrode Terminals of Rechargeable Battery