Partially soft-gold plated parts・Hoop plating

This product is manufactured and sold by FINECS.

index

Product characteristics

Sub-plating is done with nickel, for finishing soft-gold (gold purity 99.99 %) is used.

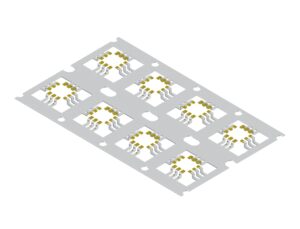

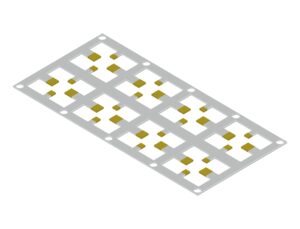

Plating is applied only to those areas where it is necessary to hold the amount of gold used at a minimum.

Reference specifications

Plate thickness t = 0.1mm ~

Material

Brass and other (please tell us about your preferences)

Main applications

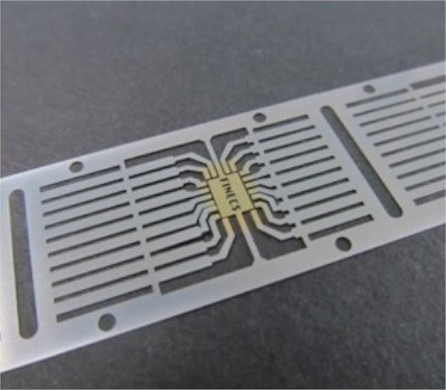

Improved semiconductor wire bonding properties.

Partial plating on lead frames for wire bonding is also possible.

What is soft-gold plating?

Soft-gold plating is gold plating with high gold purity (must be 99.9% or higher)

It shows low contact resistance and excellent wettability and adhesion to other materials (easiness of familiarity).

Suitable for wire bonding and connection of semiconductor parts.

Soft-gold plating characteristics and wire bonding

For wire bonding gold, silver or aluminum wire with a diameter of 10 to several 100 μm is used. The goal of this method is to electrically connect electrodes of a semiconductor chip with conductors on a lead frame or substrate.

Compared to soldering, wire bonding requires high reliability in tiny areas. The wire is joined and connected to the surface by heat or ultrasonic waves.

Soft-gold plating is suitable as a surface treatment for wire bonding due to its characteristics (adhesion and wettability).

In addition, because it has excellent conductivity, corrosion resistance, workability, and chemical stability, it is also suitable for either long spans where there is a large distance between the chip electrode and the lead frame, as well as for fine pitch bonding where the distance between the leads is very narrow.

The disadvantage of soft-gold plating is being more expensive than silver and aluminum, but by plating only the necessary parts, the costs for gold material can be reduced and effectively be controlled.

At FINECS, we are continuously working on research and development of our technologies to further reduce production costs, thus reaching for higher satisfaction of our customers.

Gold hoop plating

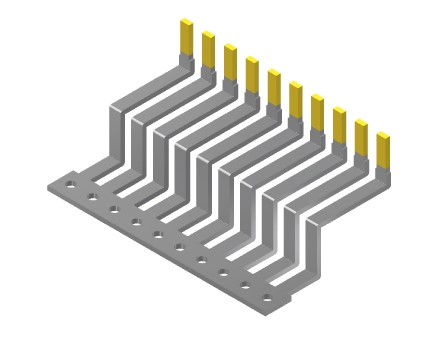

Hoop plating is a method to apply plating to a roll-shaped object continuously and at high speed.

The metal material - either roll-shaped or wounded on a reel – is stretched and continuously passed through the sub-plating and finishing processes, until it finally gets wounded again at the end.

Compared to rack plating and barrel plating, products can be processed continuously from material supply to the plating itself, resulting in high productivity and excellent product stability.

Depending on the conditions, the treatment costs can be reduced by applying hoop plating of material rather than execute post-plating to an already processed product. There are also cases where products that were conventionally treated with barrel plating may be hoop-plated.

| ① | Pre-processing | Removal of oil and oxide film from the material |

| ② | Sub-plating | Adjust the condition (surface) of the material and improve the adhesion |

| ③ | Finishing | Gold plating |

| ④ | Post-processing | Cleaning / drying / winding |

(Gold hoop plating process)

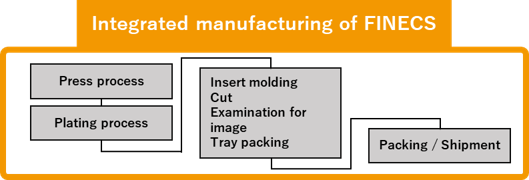

Integrated production of FINECS

We have manufacturing equipment that can consistently produce from terminal press processing to plating processing, insert molding, and automatic assembly.

This enables quick quality feedback, resulting in reduction of in-process defects and costs.

For semiconductor soft-gold plating – which requires a uniform surface condition – we deliver the quality required by our customers and are able to provide highly competitive plating.

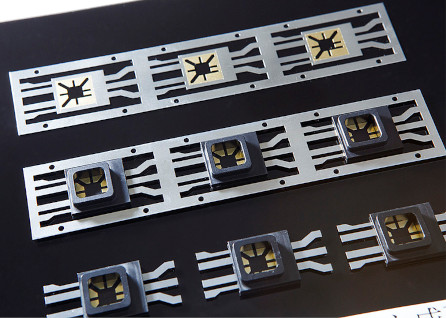

(Pressure sensor case for vehicles)

We manufacture pressure sensor cases for automobiles with soft-gold plating, as well as various insert-molded and integrally-molded products.

We also have great experience in in-vehicle related products.

Please refer to the following page for more details.

Related page: Integrated Manufacturing of molded parts

Related page:Our automotive related products

- ※Specifications, materials, and other details are available upon request.