Recommended Case Examples(1)

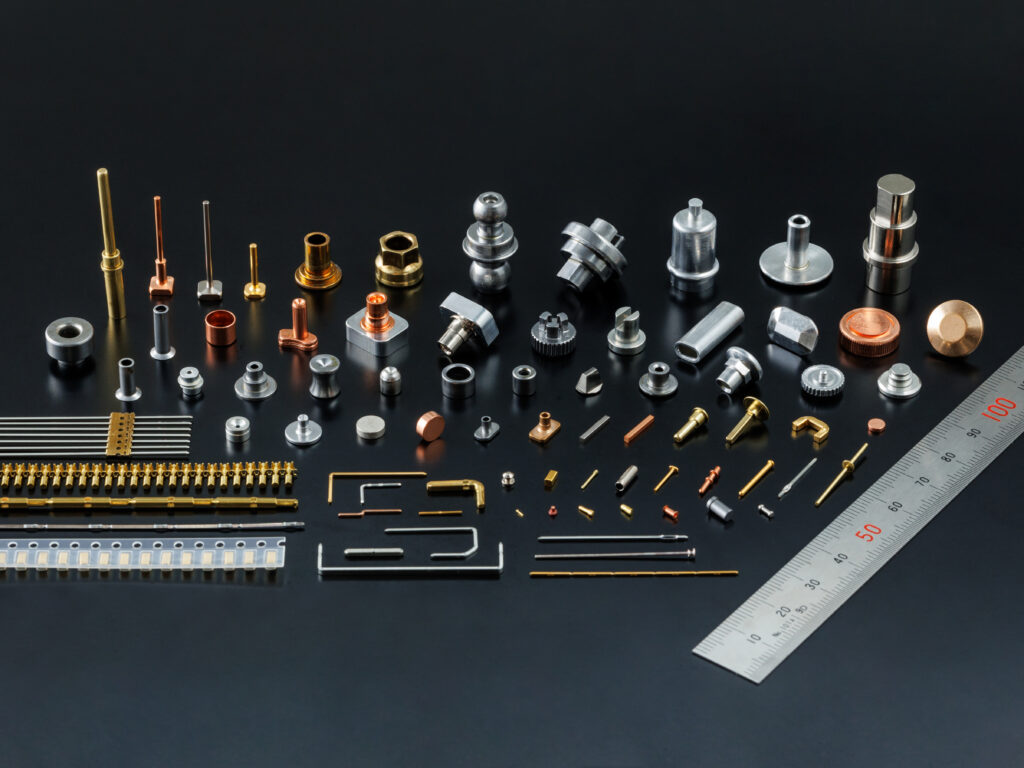

Manufacturing of non-standard shape parts from wire

FINECS has a proven track record of processing wire into various shapes.

Using various methods, including hitting, bending, cutting, crushing, making holes in, making patterns in and rounding the corners of wires, we can make them into any shape according to the customer's requirements.

Wire is used, so there is no waste of material, and almost no scrap is produced, so our products are environmentally friendly.

※Click here for a list of FINECS products

Recommended Case Examples(2)

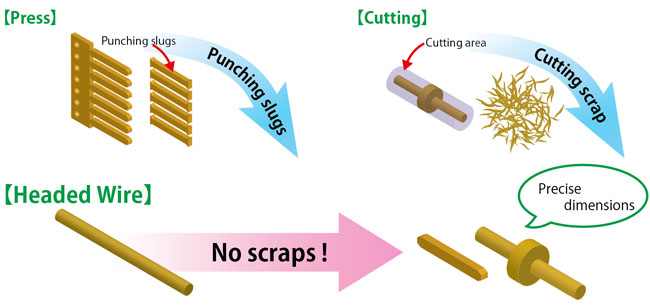

Switch from press-formed terminals and machined pins

Our headed wire products do not generate cutting scrap or punching slugs.

Material lost can be kept to a minimum, so we can provide low cost products.

We can also make the products to precise dimensions.

Recommended Case Examples(3)

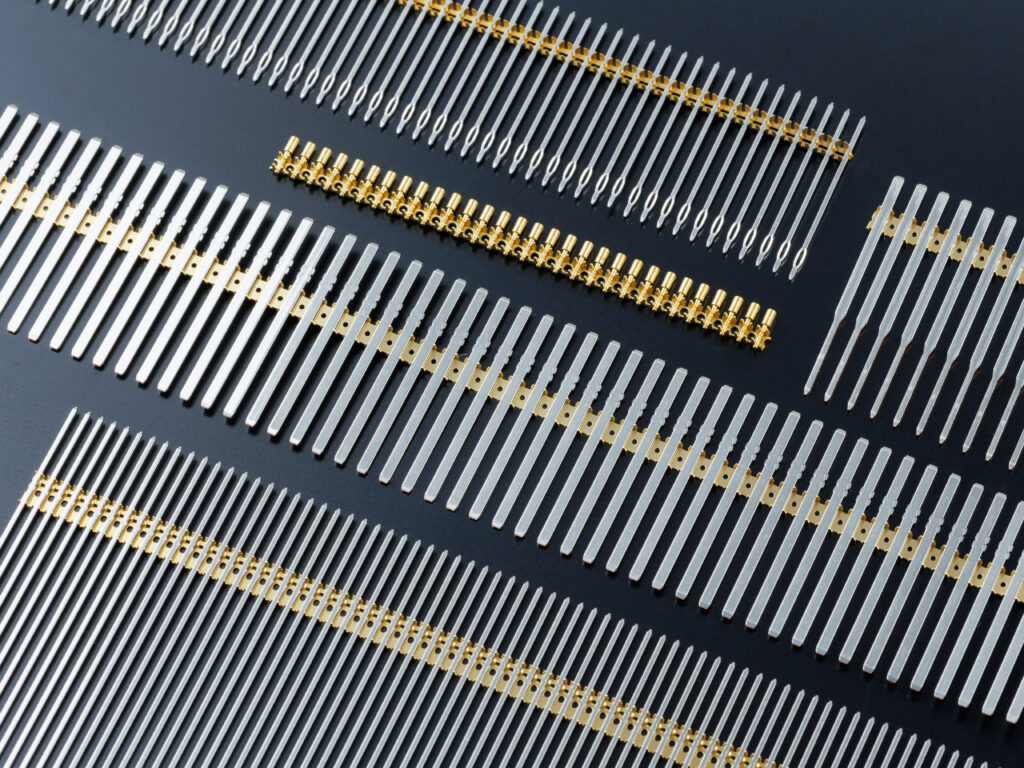

Bandolier terminals (switch from press-formed items)

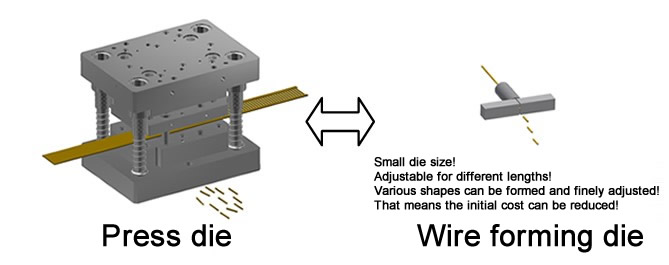

Proposal to reduce initial cost of dies

A large initial die investment is required for press-formed terminals made from hoop material, and expensive dies are required every time there is a change in the product dimensions.

With wire, no die is necessary for adjusting length, so dimensions can be changed by simply adjusting the feed.

Additionally, various forming is possible, such as tapering the end or crushing the press-fit piece.

Eco-friendly proposal for reducing scrap material

In regular press work, there is a large amount of metallic waste produced outside the part that becomes the product.

With wire, the material is formed (crushed, stretched, etc.) as-is, so almost all of the material is used in the product, making it possible to substantially reduce metal scrap.

Securing 4-face plating of terminal sides

With press-formed items, the base material on the sides punched out is exposed, so if the sides need to be plated, it has to be done afterwards.

With wire, on the other hand, there is no need to punch out the material, so the base material is not exposed after the forming process. (The base material is exposed at the end of the pin where it is cut.)

Stabilization of terminal profile shape

With press work, the shape of the terminal can become deformed due to the large amount of pressure applied in the punch out process.

With wire, however, stable forming is possible while maintaining the profile shape.

FINECS’ proprietary processing method also enables very precise processing of crushed and constricted product shapes.

Highlighted Case Examples(4)

Various processing and assembly proposals

We will propose the optimal method from our repertoire, which includes metalwork parts, molded items, surface treatment (plating), assembly, dies, automatic processing machines, automatic assembly machines and inspection equipment.

We are especially capable with board mounted parts, sensor-related parts, connector-related parts and test checker parts.

Terminal + molded item proposals

Terminal + molded item proposals Terminal + surface treatment proposals

Terminal + surface treatment proposals Terminal + molded item + surface treatment + assembly proposals

Terminal + molded item + surface treatment + assembly proposals Surface treatment proposals

Surface treatment proposals Automatic production machine + assembly proposals

Automatic production machine + assembly proposals

Highlighted Case Examples(5)

Finecs' environmentally conscious products

As a globally expanding manufacturing company, we strive to develop and provide environmentally conscious products to meet the expectations of our customers around the world through our products, while at the same time contributing to the preservation of the global environment and the formation of a recycling-oriented society. We strive to reduce the environmental impact of our products, beginning from their production throughout their life cycles. Through the use of our products, we support our customers' ISO14001 activities and thus strive to realize a society with low environmental impact.

Press-fit terminal pin

Press-fit terminal pin Various wire rod terminal pins, various crimp parts

Various wire rod terminal pins, various crimp parts Electro-mechanical parts

(press-fit assemblies, insert molded products)

Electro-mechanical parts

(press-fit assemblies, insert molded products)