- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

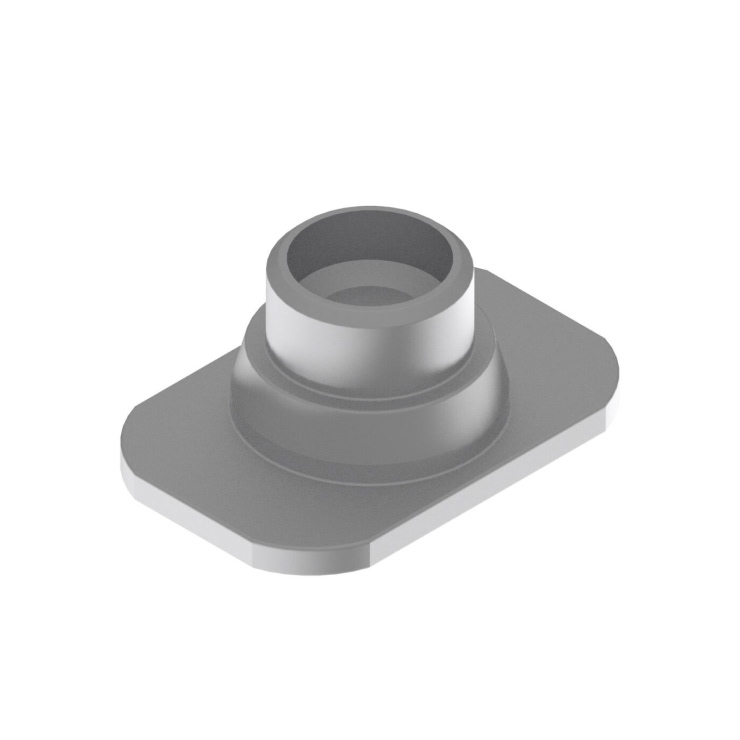

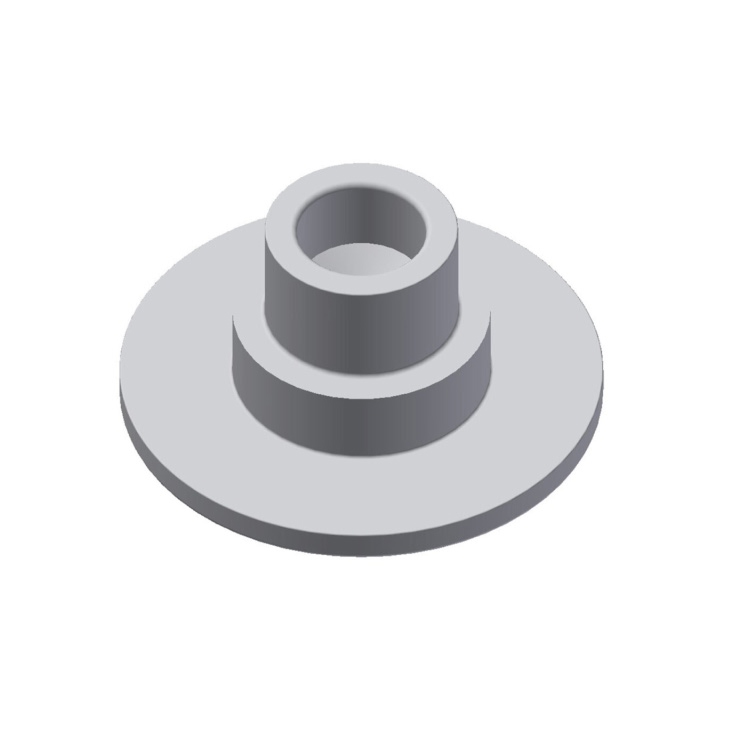

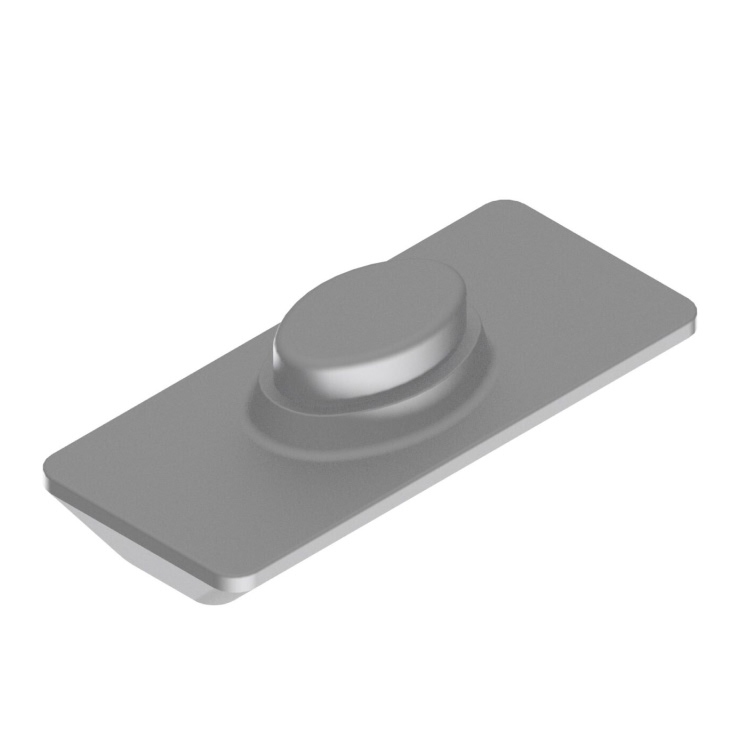

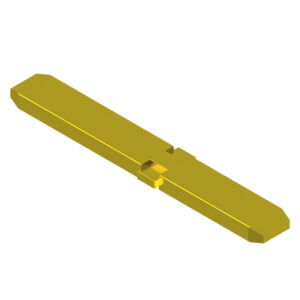

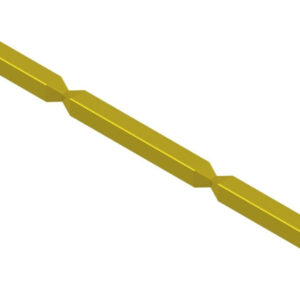

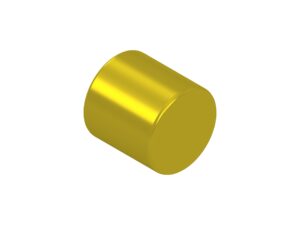

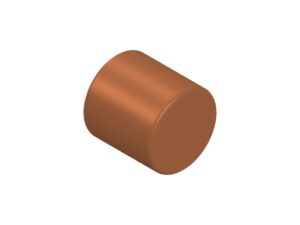

Electrode Terminals of Rechargeable Battery

This is a terminal used for cathodes / anodes of automotive or consumer rechargeable battery (e.g. nickel hydrogen batteries, lithium-ion batteries, and more)

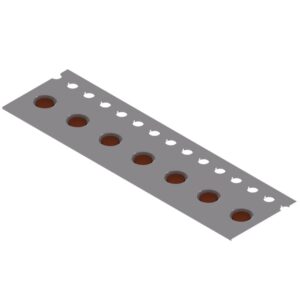

We also offer in-vehicle lithium-ion secondary batteries, as well as headed or pressed current collector plates and terminals for capacitors (condensers).

Based on our current manufacturing records of secondary battery terminals, we are also planning to produce terminals for all-solid-state batteries. If you are considering the use of terminals for all-solid-state batteries, please feel free to contact us.

| Reference standard | Aluminum terminal Shaft diameter φ3.0~φ10.0, Head diameter φ3.0~φ20.0 Copper terminal Shaft diameter φ3.0~φ10.0, Head diameter φ3.0~φ15.0 |

Main usage

Positive (electrode) and negative (electrode) terminals for automotive secondary batteries and all-solid-state batteries

Our products are used for the positive and negative electrodes of secondary batteries (lithium ion batteries, etc.) installed in next-generation vehicles such as HEVs (hybrid vehicles), PHVs (plug-in hybrid vehicles), and EVs (electric vehicles). We are also putting effort in the manufacturing of terminals for all-solid-state batteries.

In addition, the current collector plates and terminals are also used in capacitors which work as power assistants during vehicle acceleration, energy regeneration, engine starting, and more.

In accordance with “CASE”, the recent years showed a rapid improvement of performance and fuel efficiency of automobiles, leading to further miniaturization and weight reduction of components. Do not hesitate to contact us, if you are looking for high quality current collector plates or terminals to fulfill these requirements.

Characteristics of automotive rechargeable battery terminals manufactured through our Heading Technology

Automotive rechargeable batteries consist of a positive and a negative electrode, where copper and aluminum are used as terminal parts. At FINECS, we use our Heading Technology to produce those Electrode Terminals from copper or aluminum wires (round wires). Because the Heading process leaves nearly no waste at all, it is a very environmentally friendly production method with low material costs. The Electrode Terminals are used to seal the battery housing.

Strengths of FINECS' Rechargeable Battery Terminals

Accumulation of many years of experience in the field of Heading Technology, and sales records regarding in-vehicle lithium-ion battery manufacturers

Becoming world's top class through accumulating experience, know-how and technology for more than 50 years.

As a top-class manufacturer, we will make optimal proposals from material selection to processing conditions according to your specifications.

Our rechargeable battery terminals are provided to lithium-ion battery (battery) manufacturers, and are well received and trusted for their excellent surface condition.

FINECS' burr-free processing

In terms of quality, burrs and contamination are very important topics for automotive rechargeable batteries.For our special Heading Technology, we handle the full process from tool designing to the actual manufacturing process design ourselves. Therefore, we are able to produce with only a minimum of burr occurrence. Finally, we will offer you very clean Electrode Terminals for your automotive rechargeable batteries (car battery terminals).In addition, during material cutting and heading, the optimum cut surface is achieved by adjusting the shape of the cutting edge, processing conditions, and die dimensions.

Great amount of Heading Machines

We have a large number of Heading Processing Machines (2D3B, 4D5B). We will select the most suitable processing machine according to the product's shape and wire diameter.

Automated clean production line

According to your needs, we can also propose an automated full production line, including the processing machines, cleaning machines, and image inspection equipment. By automating, it is possible to eliminate work mistakes, reduce manufacturing costs, and build a self-process-completed manufacturing line.

In addition, we can design the image inspection device to measure all points you request. By laying a great focus on non-contamination, we produce on a environmentally friendly and well-maintained manufacturing floor, thus ensure in-vehicle quality.

* If you have any requests regarding wire diameter, length, plating, quality, etc., please feel free to contact us. We are happy to help you.

関連リンク

Products with the Same Processing Method

-

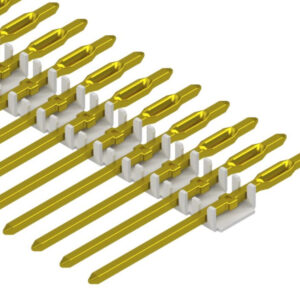

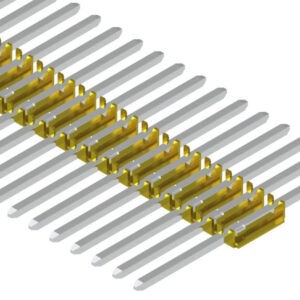

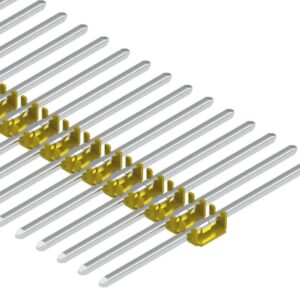

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

Deep drawn pins / cups -

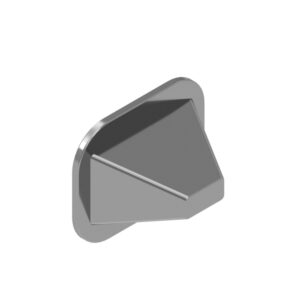

Pyramidal pins -

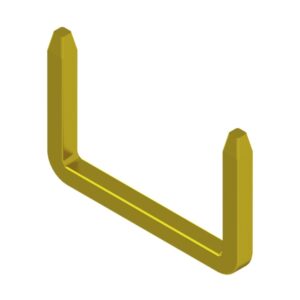

U-shaped pins Pyramidal pins -

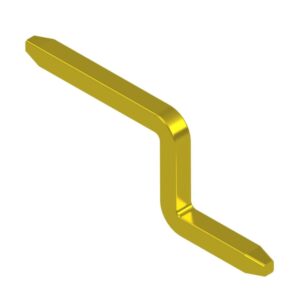

Crank-shaped pins Pyramidal pins -

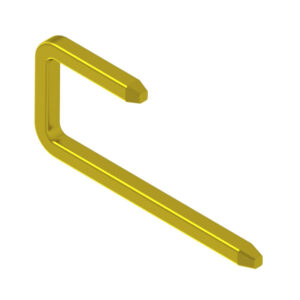

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

„ear-crush“ flat square with pyramid taper -

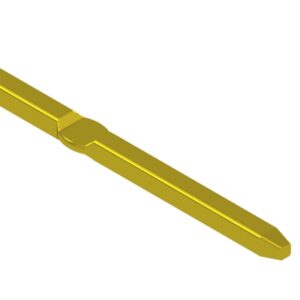

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

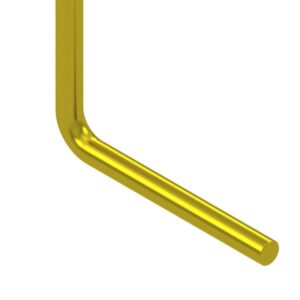

L-shaped pins (right angle) -

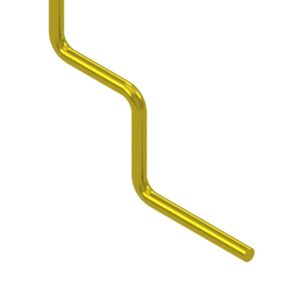

Double-step L-shaped pins -

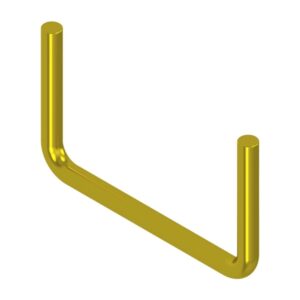

U-shaped pins -

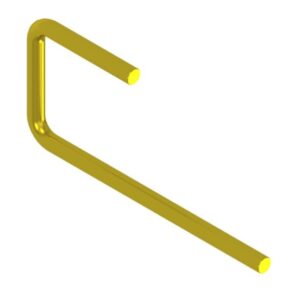

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Terminals with solder -

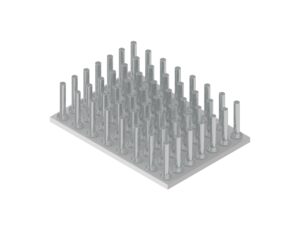

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

Hollow Rivet -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay -

Electrode Terminals of Rechargeable Battery