- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

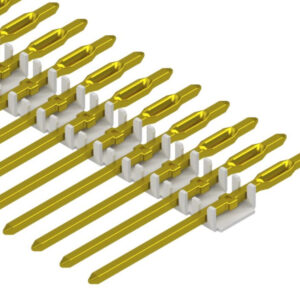

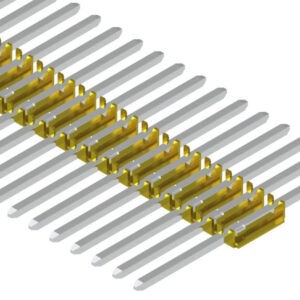

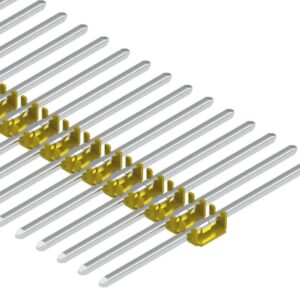

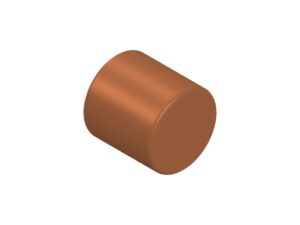

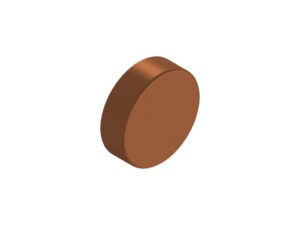

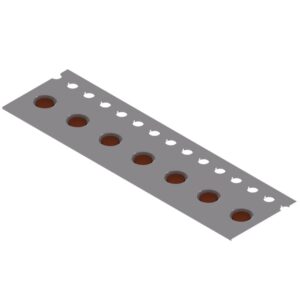

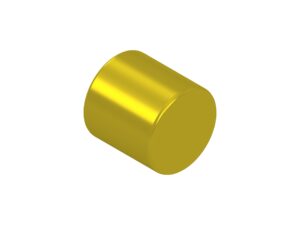

Copper Pillar pin

Our Copper Pillar pins are used in various ways and applications:

a) in semiconductor packages with a PoP structure (package on package), as used in high-speed communication devices like smartphones or other mobile 5G devices,

b) as an interconnect or interposer for a board with built-in components,

c) in combination with solder balls or plating serving as a new technology to replace bumps.

| Reference standards | φ0.06mm~ |

| Material | Cu-based metals, copper alloys |

| Plating / surface treatment specifications | Sn, Ni, Au, SAC305 and more |

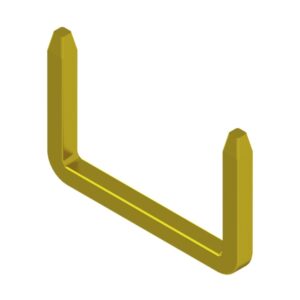

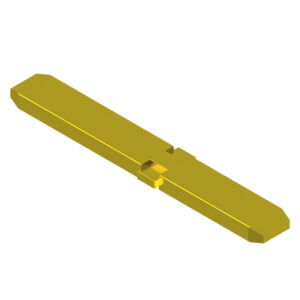

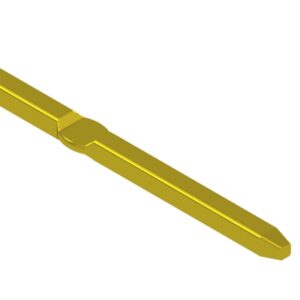

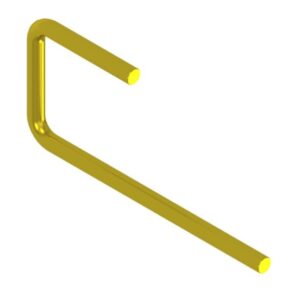

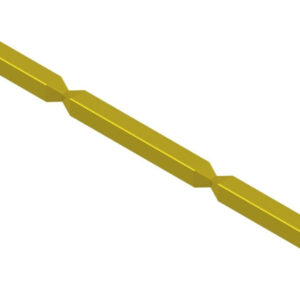

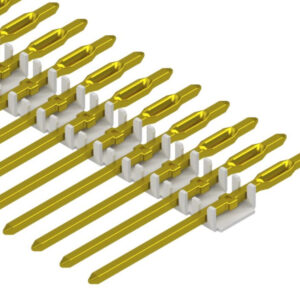

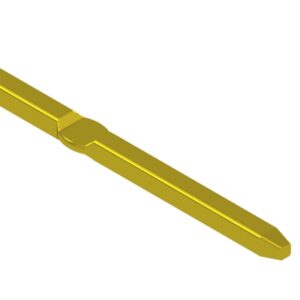

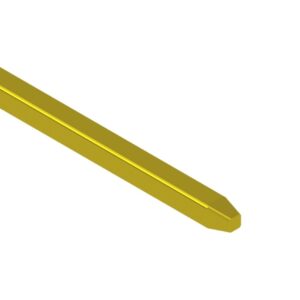

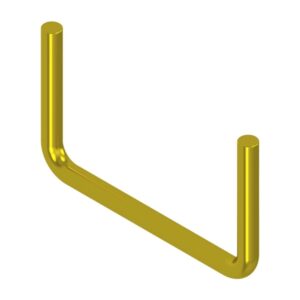

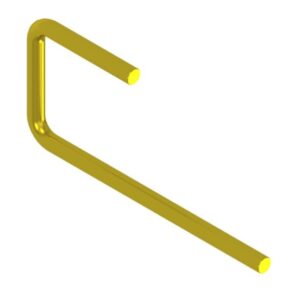

| Shapes | Straight type Cu pin (cylinder) , Header type Cu pin (T-pin) |

Main applications

As an interconnect within semiconductor packages

PoP (Package on package), FOWLP (Fan-out wafer level package), SiP (System in Package), SoC (System on Chip), 2.5D / 3D package and more. As an connector terminal or pin for interposers for all types of semiconductor IC packages.

What is Copper Pillar pin?

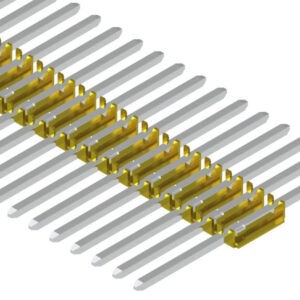

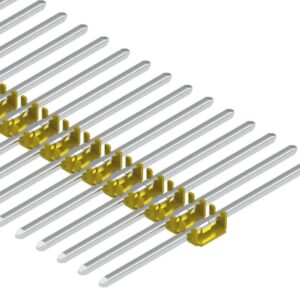

There are two main methods for Copper Pillar pin processing: one involves stacking copper (Cu) pillars through plating, and the other arranges micro terminal pins. Leveraging our long-standing expertise in manufacturing micro terminal pins, we can stably supply high-precision micro terminals—micro pins—that can be used as copper pillars (Cu Pillar), copper posts (Cu Post), or copper pins.

To accommodate the increasing number of terminals resulting from the higher integration of semiconductor chips, we replace conventional solder bumps, solder balls, and plated copper posts with micro-diameter copper (Cu) pins arranged in cylindrical post shapes. These serve as electrical interconnections and interposers for semiconductor chips and packages.

This approach enables narrower pitch designs while allowing flexible height configurations. Furthermore, by transitioning from point contact to surface contact, we achieve enhanced bonding strength.

Comparison of Copper Pillar pins, solder balls and plating laminates

| Copper pillar pin | Solder ball | Plating laminates | |

| Height Pitch | H:Flexible P : Narrower pitch possible than with solder ball of same size  | H<P possible Narrow pitch not possible Only with same height(H) and pitch (P)  | H>P possible Narrow pitch possible)  |

| Connection | Strong (surface contact)  | Weak (surface contact)  | Strong (surface contact)  |

| Shape | Choosable (straight,T-shape,etc)  | Ball shape only | Cylindrical ※In case of lamination only cylindrical shape  |

* Specifications, materials, and other details are available upon request.

Related Links

Frequently Asked Questions about this Product

-

About copper pillar, how do you manufacture it?

Our original equipment is manufactured by press-forming (cold forging) which processes wire materials by methods such as cutting and tapping.

Products with the Same Shape

-

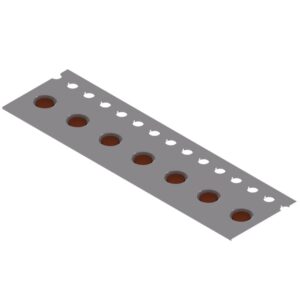

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

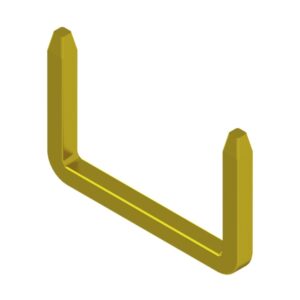

U-shaped pins Pyramidal pins -

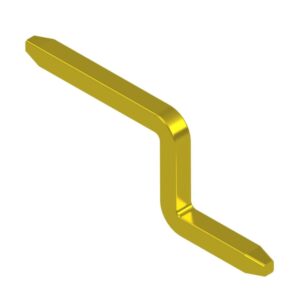

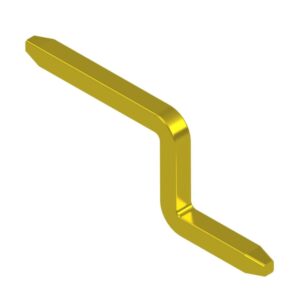

Crank-shaped pins Pyramidal pins -

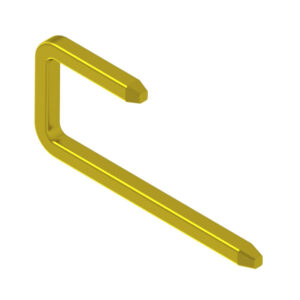

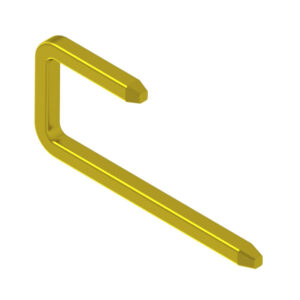

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

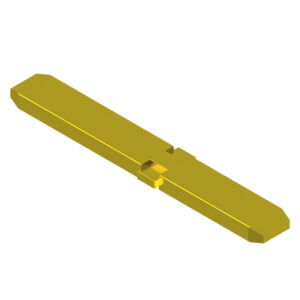

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

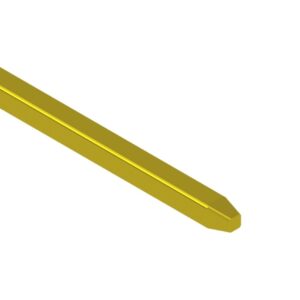

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

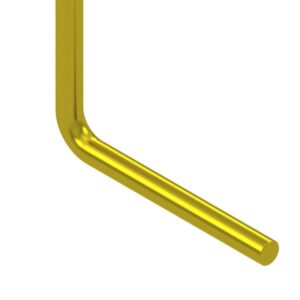

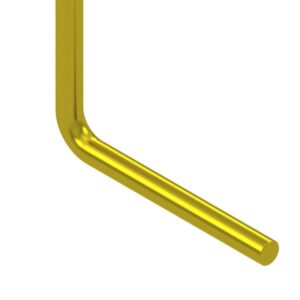

L-shaped pins (right angle) -

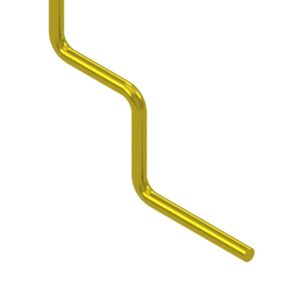

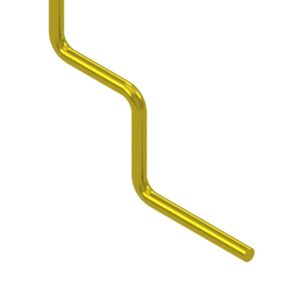

Double-step L-shaped pins -

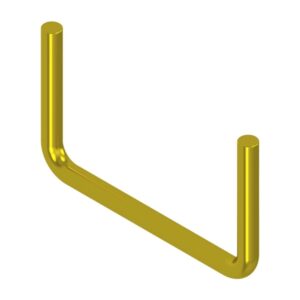

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Connector Assembly with Wire Terminals -

Surface Treatment (Plating) -

Terminals with solder -

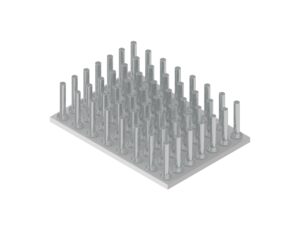

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay

Products with the Same Processing Method

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

Deep drawn pins / cups -

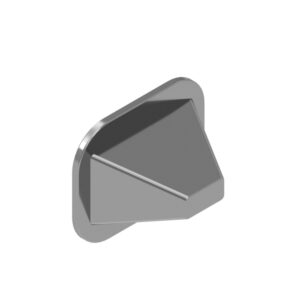

Pyramidal pins -

U-shaped pins Pyramidal pins -

Crank-shaped pins Pyramidal pins -

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

L-shaped pins (right angle) -

Double-step L-shaped pins -

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

Hollow Rivet -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay -

Electrode Terminals of Rechargeable Battery