- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

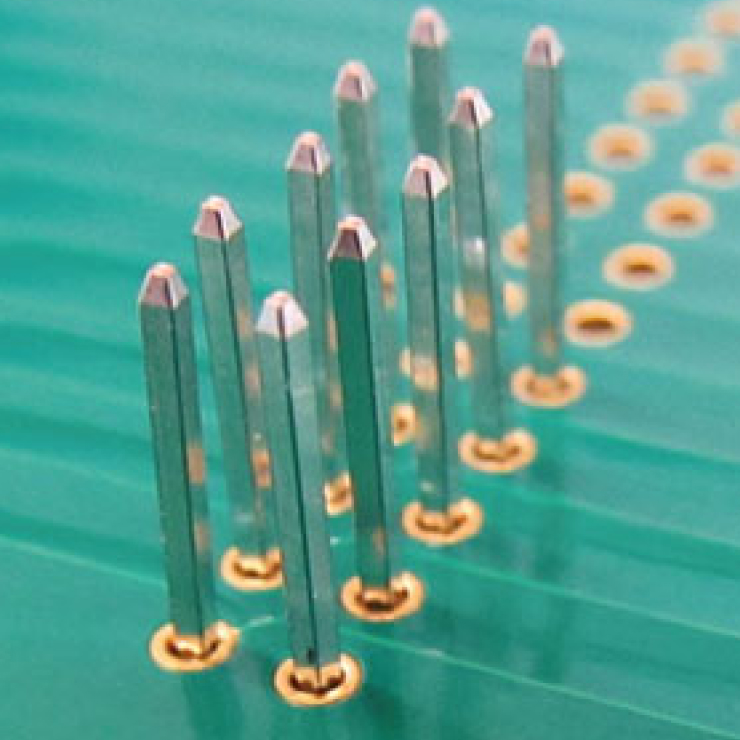

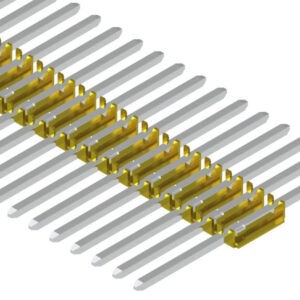

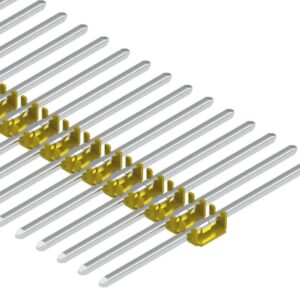

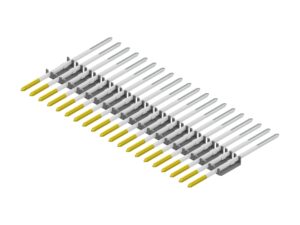

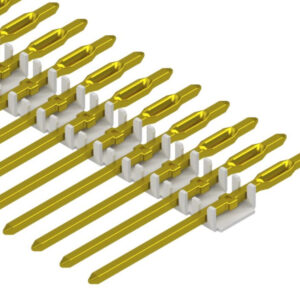

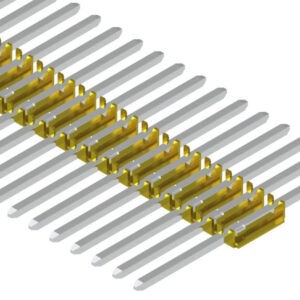

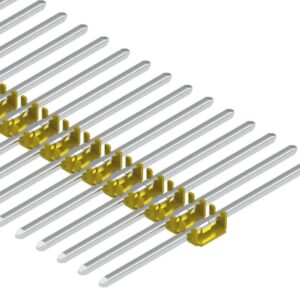

Press-fit terminals (from wire)

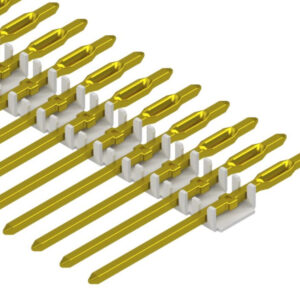

In recent years, demand for products that reduce solder usage has grown due to cost and environmental concerns. FINECS’ press-fit terminals meet these needs perfectly. With decades of cold forming expertise, we developed our own Cold Heading Technology for more precise and efficient manufacturing. This process produces no metal scraps and operates faster than other methods, helping customers cut costs and increase profits. We supply press-fit terminals for automotive and consumer connectors, as well as IGBT and SiC modules, tailored to your requirements.

Request a quote or prototype| Reference standards | □0.64mm ※ for rectangular wires or any other type, please contact us. |

| Material | Considering Press-fit pin applications, we recommend C5191 (phosphor bronze), because of its high springiness. In recent years – as a result of the accelerating growth of the information society – C7025 (Corson alloy) has gained attraction due to its high electrical conductivity. |

| Plating | Our basic procedure is: Ni sublayer + Sn (Reflow) plating. For other plating specifications, please contact us. |

Applications

Replacing conventional connector terminals.

Connectors in automotive / consumer , automotive lights / sensors / actuators / motors, and more.

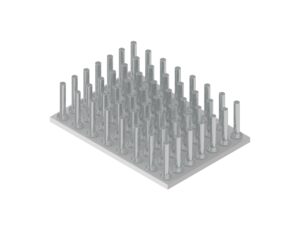

Power semiconductors (power modules)

IGBT modules, SiC modules, and more.

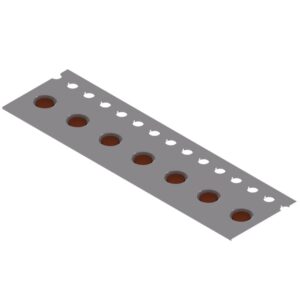

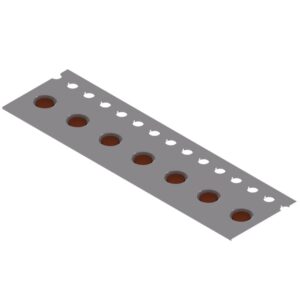

※When considering Press-fit pin usage for power semiconductors, we recommend a combination of Press-fit pins / terminals with our pin holders (sleeve pins) to secure the best connection with a substrate. Please let us know about your ideas.

Comparison with Press-fit terminals made by Press-working

Next to our Press-fit pins / terminals made from wire, we also offer Press-working to create Press-fit pins / terminals from metal sheets. Here we can provide you a very high flexibility regarding the pin shape, however please be informed that the initial costs are basically higher than those for wire processed Press-fit pins / terminals.

The latter have the advantages that no material loss occurs and initial costs are lower, but on the other hand complex shapes are difficult to handle. According to your request, we are happy to help investigate the most efficient way to create the Press-fit pins /terminals you desire. Please contact us anytime.

What is Press-fit terminal?

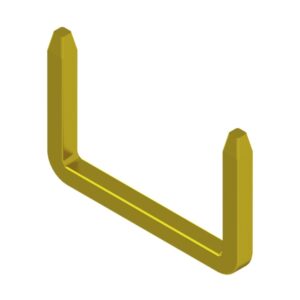

Press-fit pins / terminals are pins that are pressed into a hole with PCB and have a structure that creates a restoring force through elastic deformation to hold the pin inside that hole.

In the past, pins have been connected by using solder, but by changing to Press-fit pins / terminals it is possible to reduce the amount of solder usage, thus also reducing production costs and environmental pollution.

Related Links

Products with the Same Shape

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

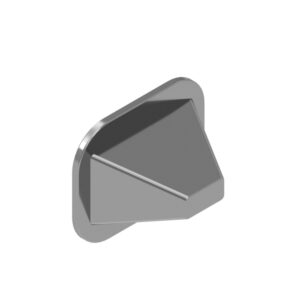

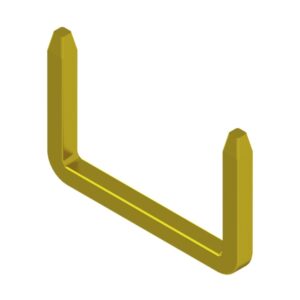

U-shaped pins Pyramidal pins -

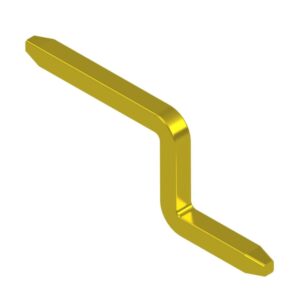

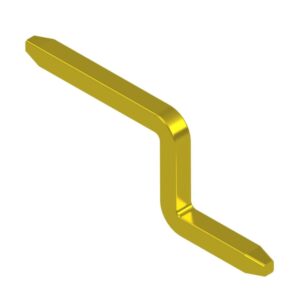

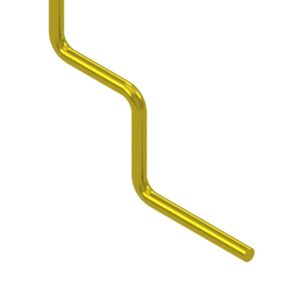

Crank-shaped pins Pyramidal pins -

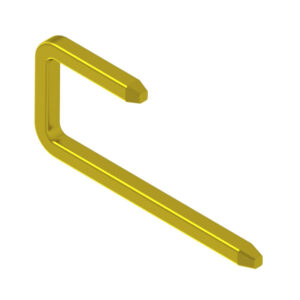

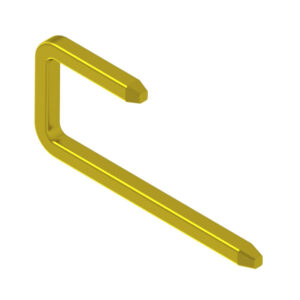

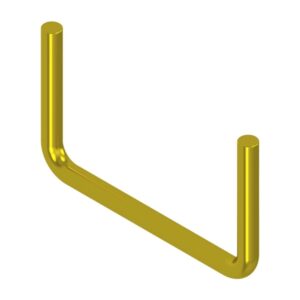

J-shaped square pins -

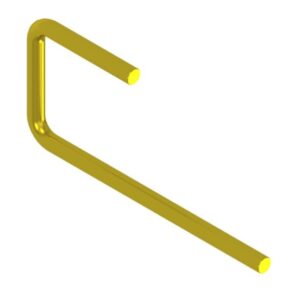

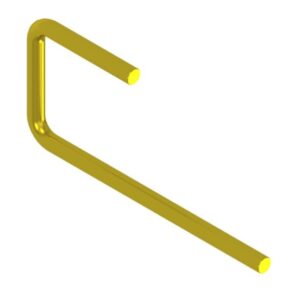

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

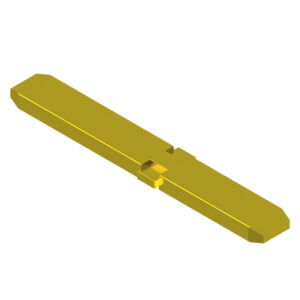

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

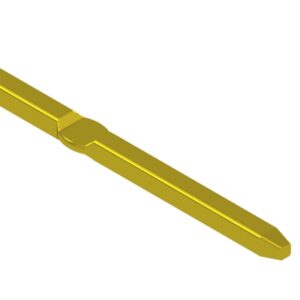

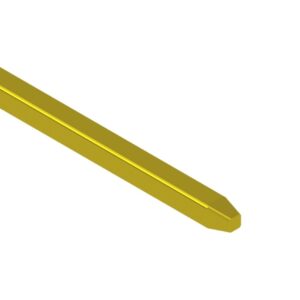

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

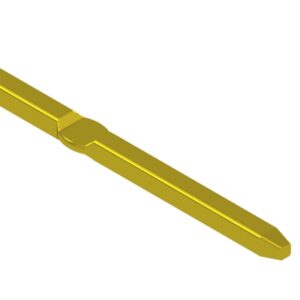

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

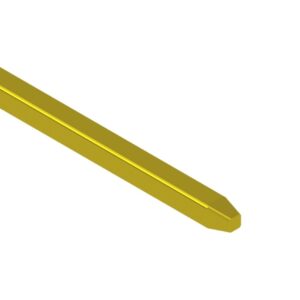

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

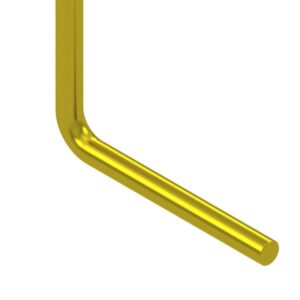

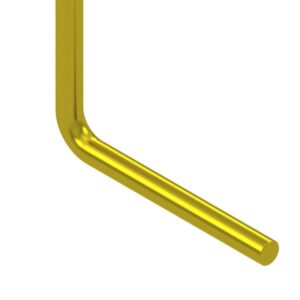

L-shaped pins (right angle) -

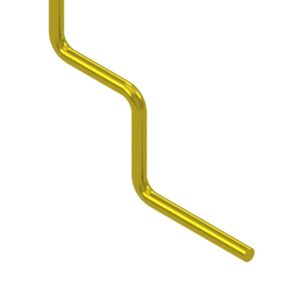

Double-step L-shaped pins -

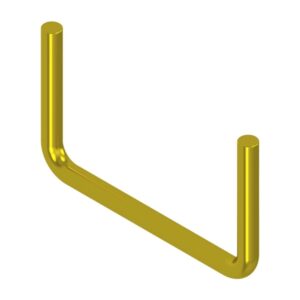

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

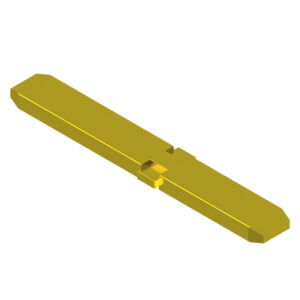

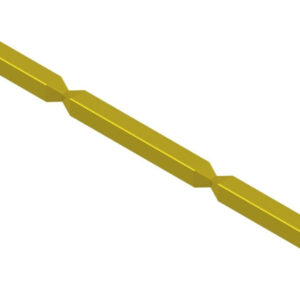

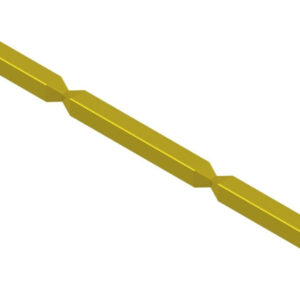

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

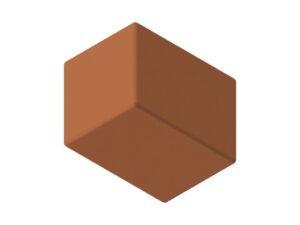

Block terminals (heat dissipation terminals and block pins) -

Connector Assembly with Wire Terminals -

Surface Treatment (Plating) -

Plated bandolier pins -

Terminals with solder -

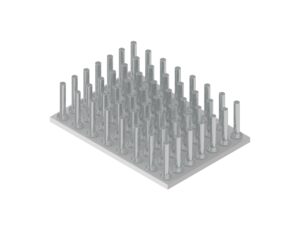

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay

Products with the Same Processing Method

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

Deep drawn pins / cups -

Pyramidal pins -

U-shaped pins Pyramidal pins -

Crank-shaped pins Pyramidal pins -

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

L-shaped pins (right angle) -

Double-step L-shaped pins -

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

Hollow Rivet -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay -

Electrode Terminals of Rechargeable Battery