- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

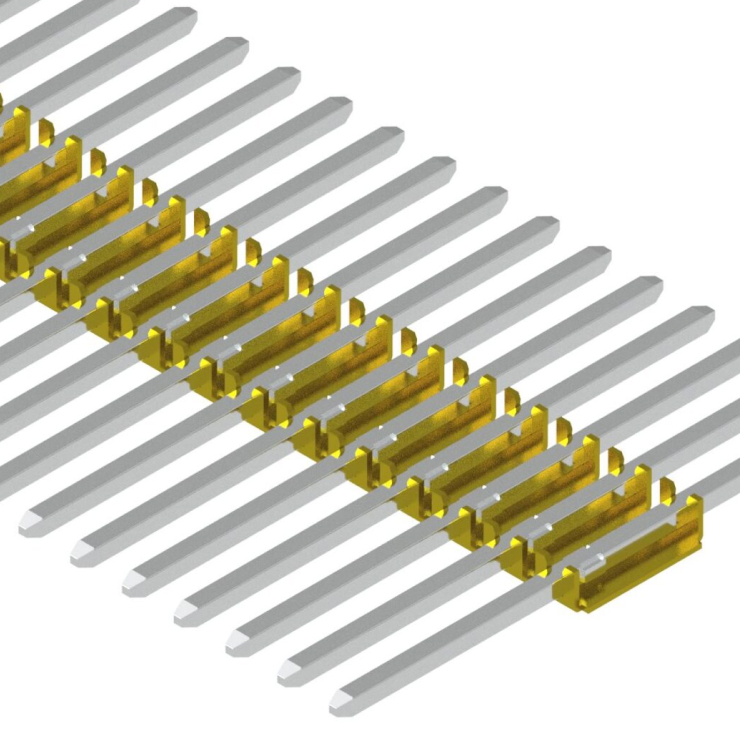

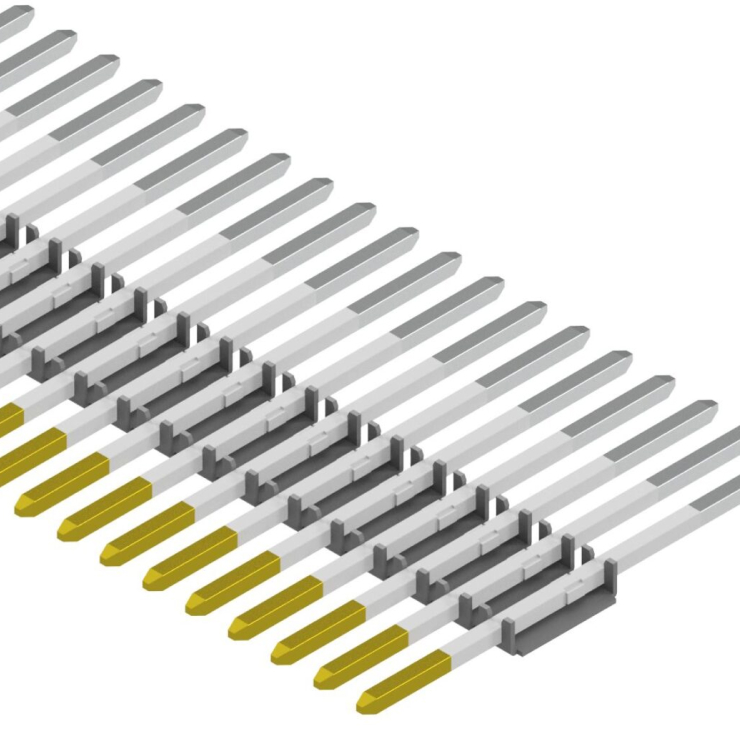

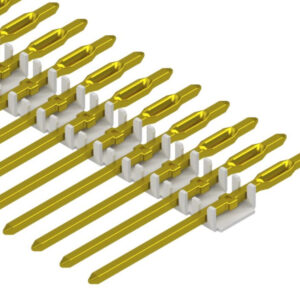

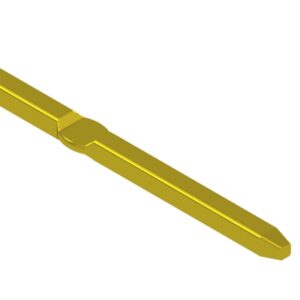

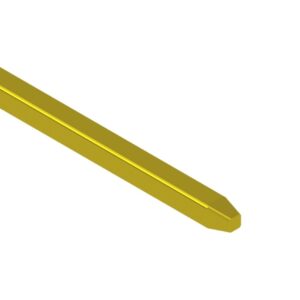

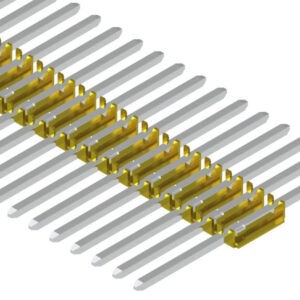

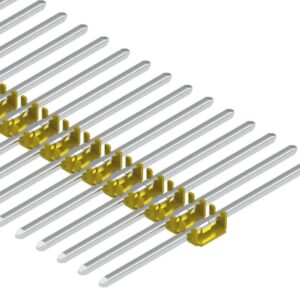

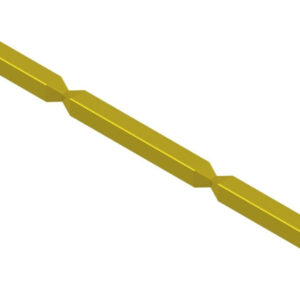

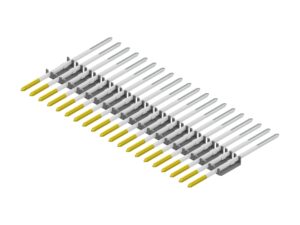

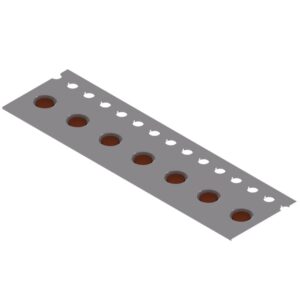

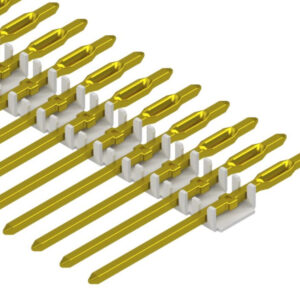

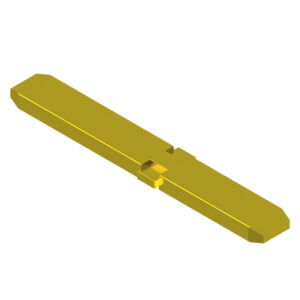

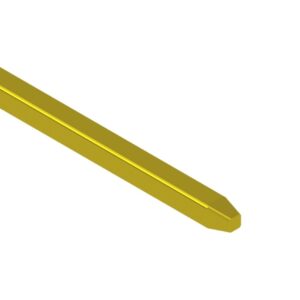

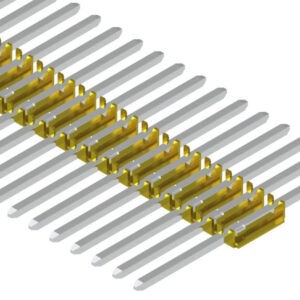

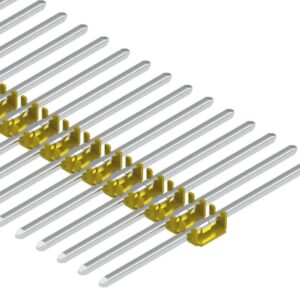

Bandolier terminals / pins made from square or flat square wires

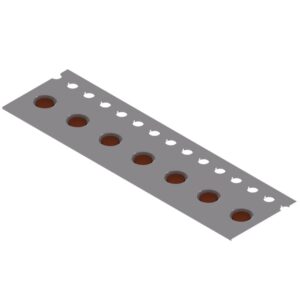

The terminals are directly planted on the band (carrier) and winded on reels afterwards. Various band dimensions are available, according to the pitch of each housing, thus increasing the number of pins that can be inserted all at once during your assembly processes, but also improving the tact time of the production line.

In case standard specifications and dimensions of pins / terminals for bandoliers are requested, no initial equipment costs will occur. (Custom-designs may differ)

| Reference standards | Possible pitches: 2.0mm, 2.54mm, 3.0mm~ Please call us for diameter, length and other related specifications Total length: As separately discussed |

| Material | Brass, phosphor bronze, or other by arrangement |

| Surface treatment | Partial gold plating, one-side tin reflow plating, overall tin plating |

Main Applications

Connector components for automotive or consumer applications, relay components and more

Advantages of Bandolier Terminals

1. All pins have the same insertion direction.

2. Bandolier with or without plating can be handled. It does not matter if you need pre-plating, post-plating or only partial plating, all types are available. Through partial plating it is possible to reduce material costs. We offer Au plating and more.

3. Compared to pressed terminals, a huge reduction of initial equipment costs can be achieved.

4. All 4 sides of the terminals can be plated.

Applicable shapes of Bandolier terminals / pins made from round wires

Straight round pins with 4-side tapers from round wires

Straight round pins with conical tapers from round wires

Partially flattened straight pins with conical tapers

Partially pinched straight pins with conical tapers

Straight pins with conical tapers and cross-shaped cross sections

Mid-flanged straight pins with conical tapers

* For details, please also refer to "Highlighted Case Examples."

* Specifications, materials, and other details are available upon request.

Related Links

Products with the Same Shape

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

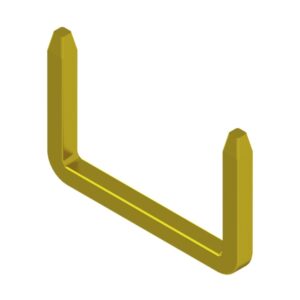

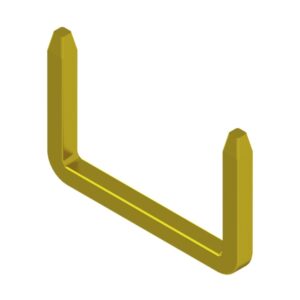

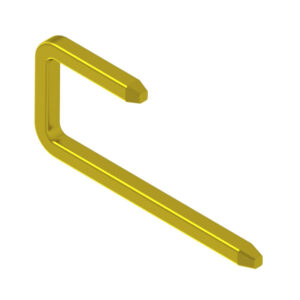

U-shaped pins Pyramidal pins -

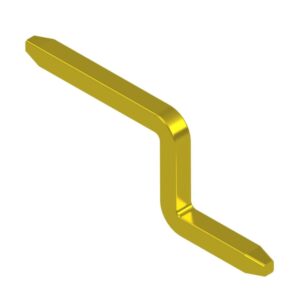

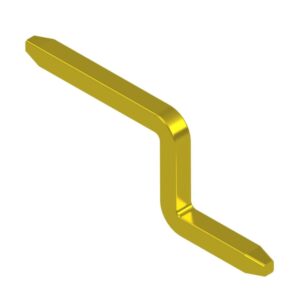

Crank-shaped pins Pyramidal pins -

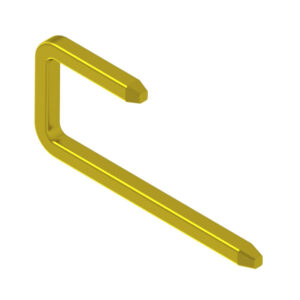

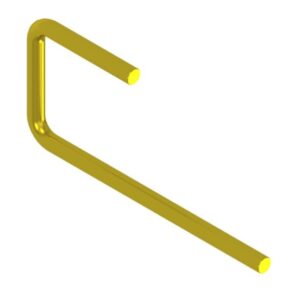

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

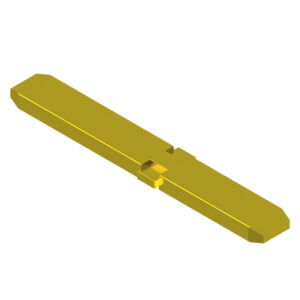

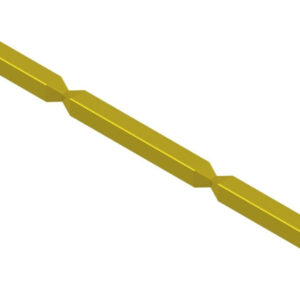

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

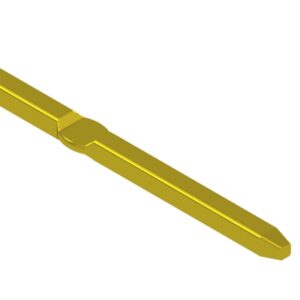

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

Block terminals (heat dissipation terminals and block pins) -

Connector Assembly with Wire Terminals -

Surface Treatment (Plating) -

Plated bandolier pins -

Connector terminals / Connector pins -

Jumper pins -

Press-fit terminals (from wire) -

Copper Pillar pin

Products with the Same Processing Method

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

Deep drawn pins / cups -

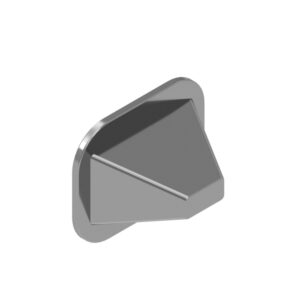

Pyramidal pins -

U-shaped pins Pyramidal pins -

Crank-shaped pins Pyramidal pins -

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

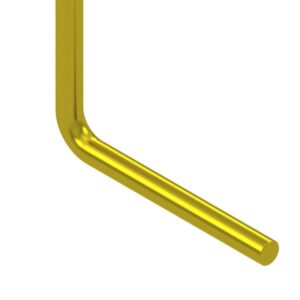

L-shaped pins (right angle) -

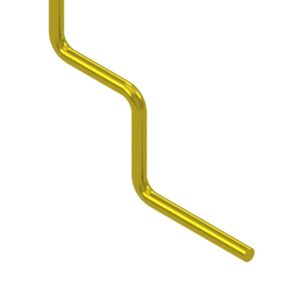

Double-step L-shaped pins -

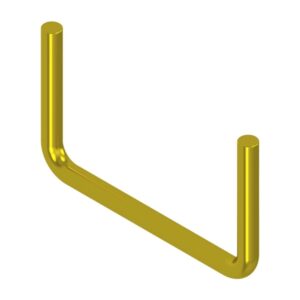

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

Hollow Rivet -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay -

Electrode Terminals of Rechargeable Battery