- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

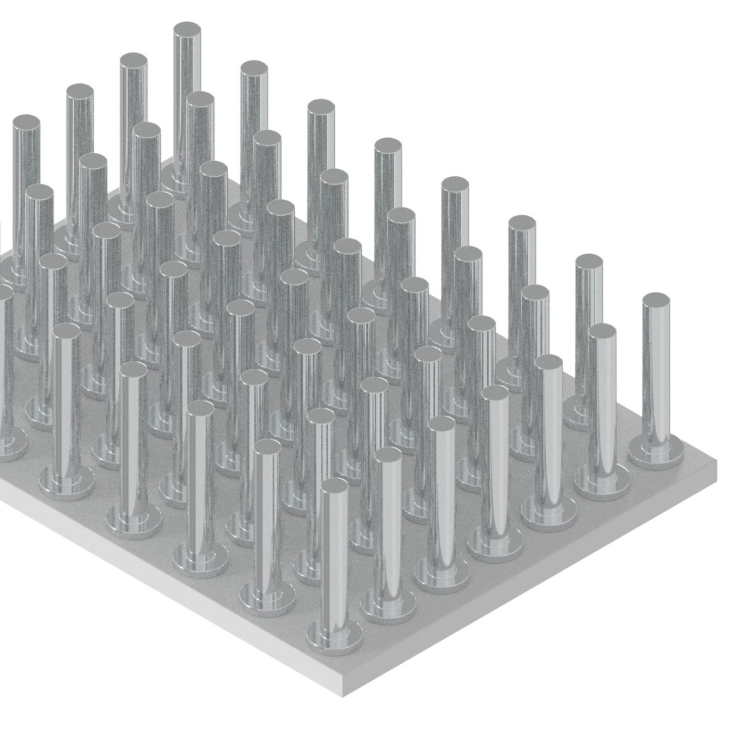

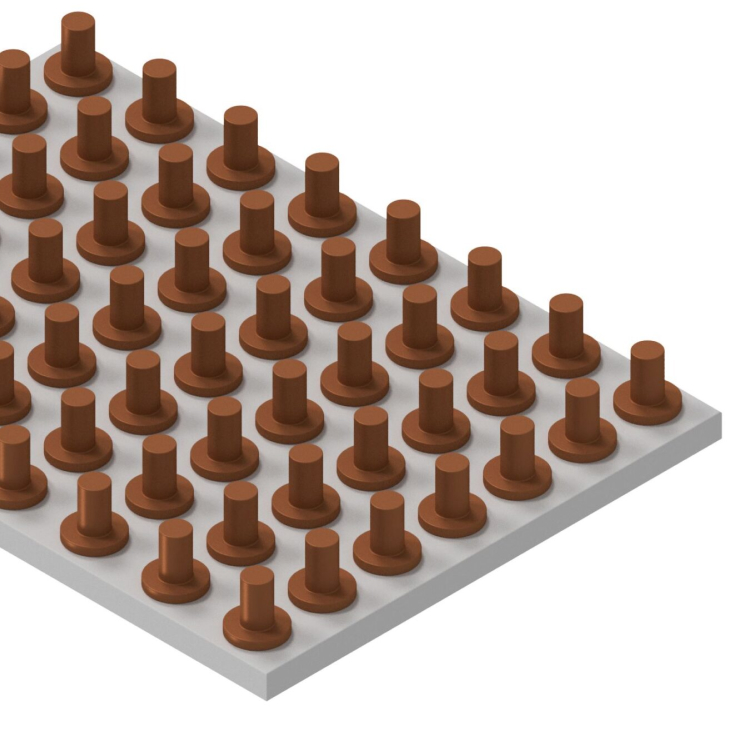

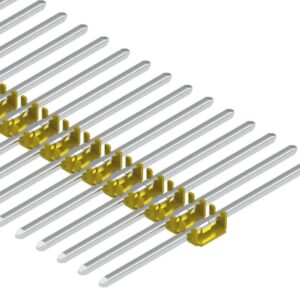

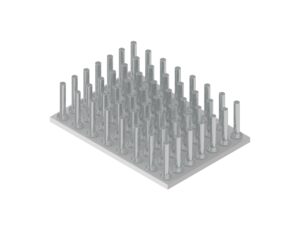

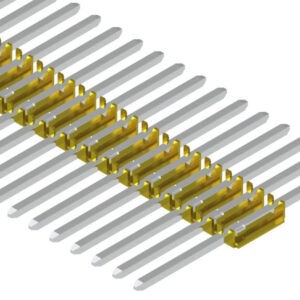

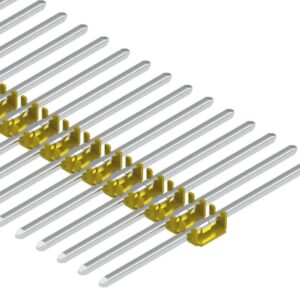

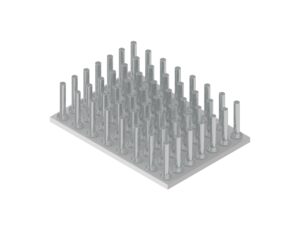

Heat radiating pins for heat sinks

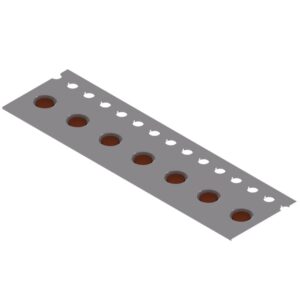

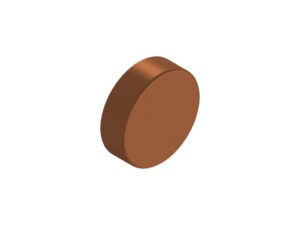

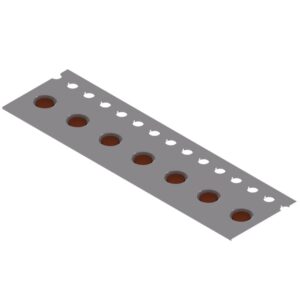

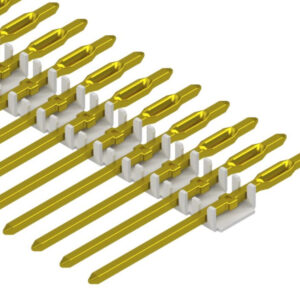

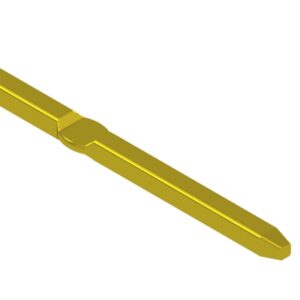

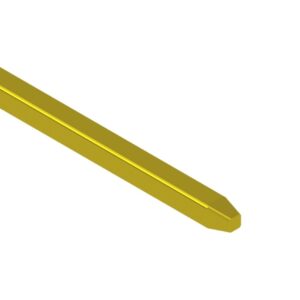

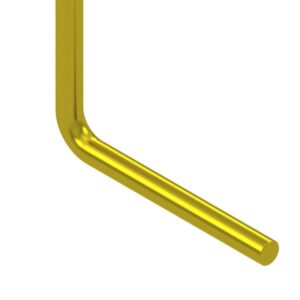

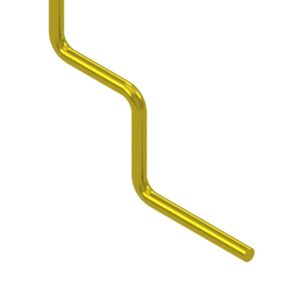

FINECS heat-radiating pins are formed from metal wires using Cold Heading Technology, reducing mold costs compared to extrusion. After shaping headers from round wire pins, they are brazed onto heat-radiating plates to create heat sinks. We offer flexibility in pin lengths and plate layouts, including long pins for superior heat dissipation. For board or IC heat management, we provide end-to-end support—from material selection to prototyping and mass production.

Request a quote or prototype| Reference standards | Round pin head: φ0.2mm and above |

| Material | Copper, aluminum, silver,etc. |

| Plating specifications | Ag、Ni、and more |

Main applications

These pins are used for various semiconductors, integrated circuit parts, laminated boards, heat sinks and more, with the main purpose of heat diffusion and heat dissipation.

Automotive

Hybrid electric vehicles (HEVs) and electric vehicles (EVs) use a large number of electronic components that require heat radiation, such as control CPUs and inverters.

Our heat radiation pins for heat sinks fit these requirements perfectly.

Wireless communication

With the spread of 5G, wireless communication in mobile phone networks is expected to increase the amount of heat generated by semiconductors as speed and capacity increase. If you need a heat radiation boards with high thermal conductivity, we offer you our heat radiation pins for heat sinks.

Railroad

IGBT modules and SIC modules have been adopted for motor controls of electric trains such as the Shinkansen. Here our pins are used to dissipate heat from these power devices.

What is heat sink?

"Heat generation" is an unavoidable phenomenon for all machines, against which various counter measures are taken.

One of these is a heat sink. This is a component that is attached to a mechanical or electrical component that generates heat, with the purpose of dissipating that heat and lower the temperature.

In order to improve the performance of the heat sink, it is brought into a shape that increases its surface area, normally a “sword-mountain” or “bellow” shape with sticks or plates (so called fins) on it.

For heat sinks mainly two different metals are used: aluminum and copper, due to their abilities to easily transmit and dissipate heat. These are two different methods to create heat sinks, the first is to extrude metal at high pressure and mold it, the other is to assemble terminals on a flat metal plate.

* Specifications, materials, and other details are available upon request.

Related Links

Products with the Same Shape

-

Embossed Taping (terminal pins & tiny components) -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

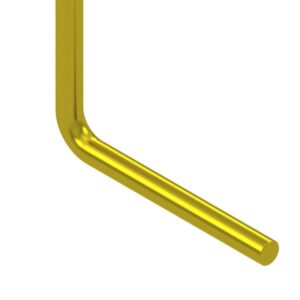

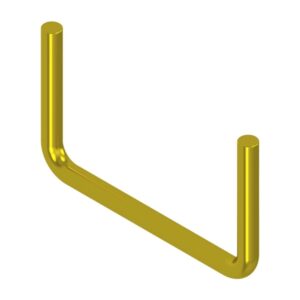

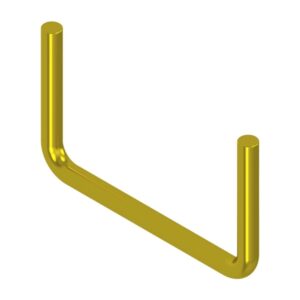

L-shaped pins (right angle) -

Double-step L-shaped pins -

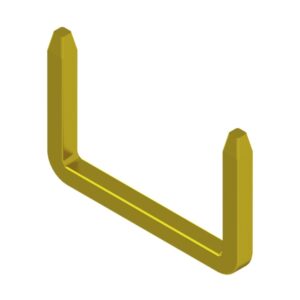

U-shaped pins -

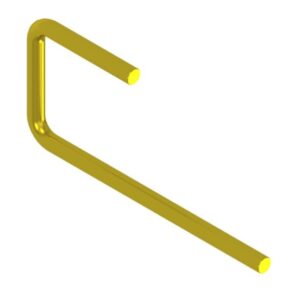

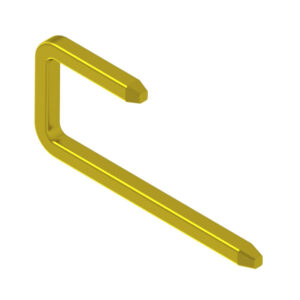

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

Mid-flanged straight pins with round chamfers -

Bandolier terminals / pins made from round wires -

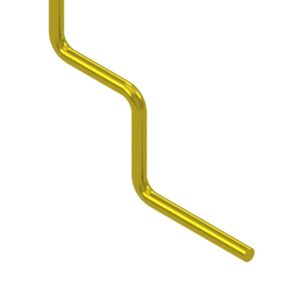

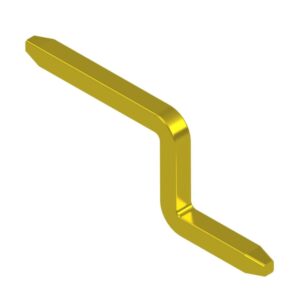

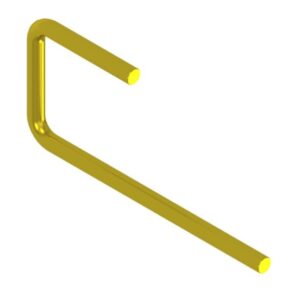

Crank shaped pins -

End-to-end pins / End-to-end terminals (round type) -

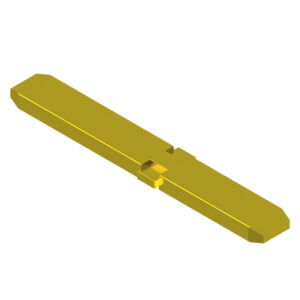

Block terminals (heat dissipation terminals and block pins) -

Connector Assembly with Wire Terminals -

Surface Treatment (Plating) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

PGA Pins (Terminals for CPUs) -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay

Products with the Same Processing Method

-

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

Deep drawn pins / cups -

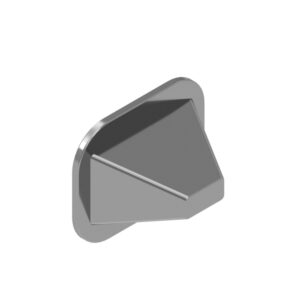

Pyramidal pins -

U-shaped pins Pyramidal pins -

Crank-shaped pins Pyramidal pins -

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

L-shaped pins (right angle) -

Double-step L-shaped pins -

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

Hollow Rivet -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay -

Electrode Terminals of Rechargeable Battery