- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

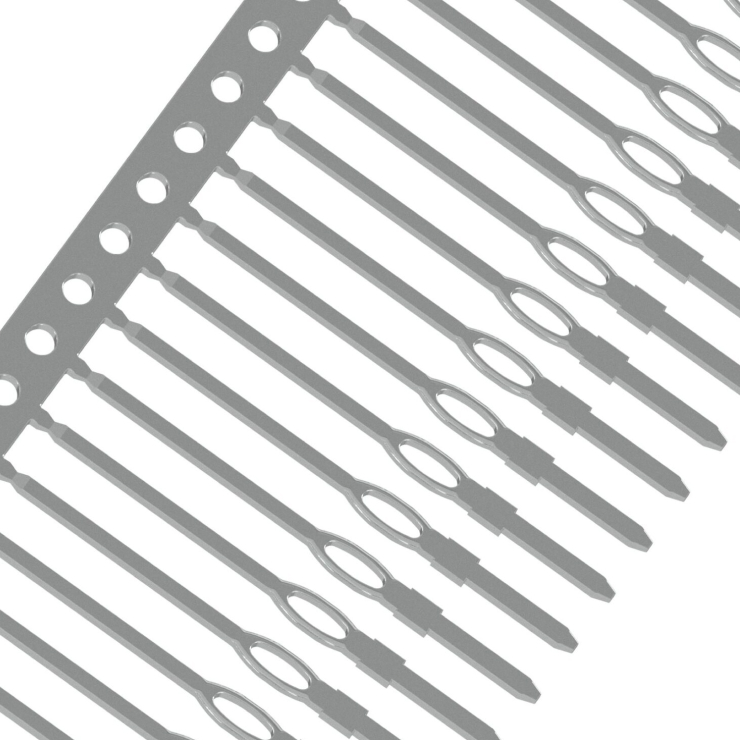

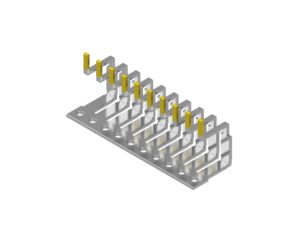

Press-fit Terminals/Pins (press-working and surface treatment)

We can manufacture press-fit terminals made from wire by cold heading and from strip material by press processing. Press-processed press-fit terminals and pins offer high design flexibility, allowing for a wide range of shapes; however, initial costs tend to be higher compared to cold heading. Press-fit terminals and pins made from wire material have no material loss and can be produced at lower initial cost, but they are less suitable for complex shapes. We will propose the most suitable processing method for the terminals you are considering.

Request a quote or prototype| Thickness of Strip material | t=0.64mm、0.8mm (also others are possible) |

| Material | C5191(Phosphor bronze) Its springiness largely increases the Pin’s retention capabilities. C7025(Corson copper) It offers high electrical conductivity and has been gaining attention in recent years with the rapid advancement of the information society. |

| Plating & Surface treatment | Ni under-plating + Sn (Reflow) |

Main application

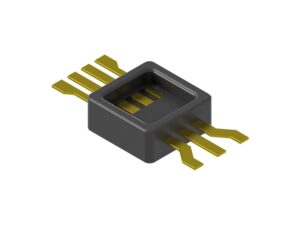

Automotive & consumer connectors, automotive lights / sensors / actuators / motors and more

What is Press-fit Pin?

Press-fit Pins are inserted into a hole, where they make us of their elastic deformation to create restoring force, thus being able to build stable structures.

This task has formerly been operated by solder, but thanks to Press-fit Pins it is possible to reduce the amount of solder usage, which further leads to a reduction of costs and environmental pollution.

For further information about Press-fit Pins, please have a look at the link below.

Related Page:About press-fit terminals and pins

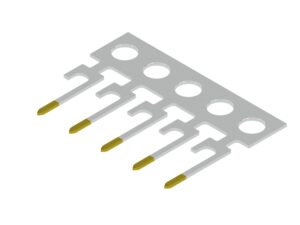

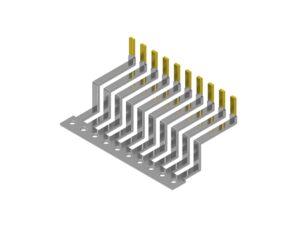

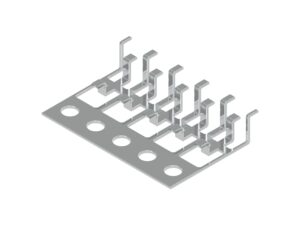

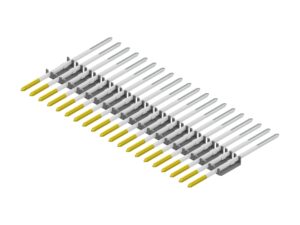

Carrier

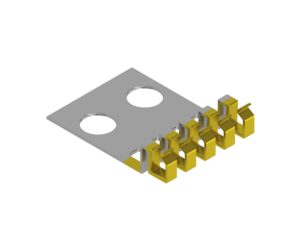

Center Carrier Press-fit Pins

Because Center Carriers make it possible to plate both ends of the terminal, they perfectly fit to insert molding products.

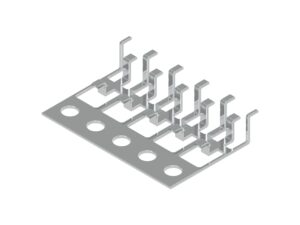

One side Carriers on the other hand can be used with Gang Insertion, making it a good choice for Connector Press-fit assemblies.

One side Carrier Press-fit Pins

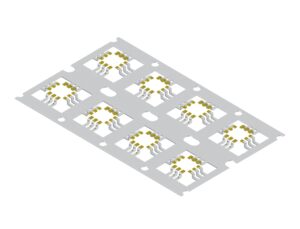

Regarding insertion molding: At FINECS we handle OEM services, making use of our Integrated Production Line – from pin manufacturing to insertion molding.

For furher information click on the link below.

Related Page:Connector Assembly with Wire Terminals

Related Links

Products with the Same Processing Method

-

Gold-plated parts -

Partial Au plating -

Partially soft-gold plated parts・Hoop plating -

Silver plating (Ag plating) / Silver Hoop plating / press & plating -

Surface Treatment (Plating) -

Plated bandolier pins -

Outer lead frame plating -

Power semiconductor terminals (press-working and surface treatment) -

Connector terminals (press-working and surface treatment) -

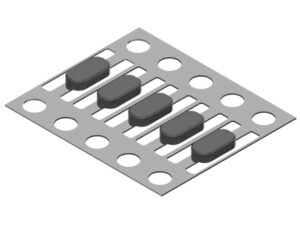

Diode terminals / connectors (press-working and surface treatment) -

Press-fit Terminals/Pins (press-working and surface treatment) -

Sensor Assemblies with Pressed Terminals