- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

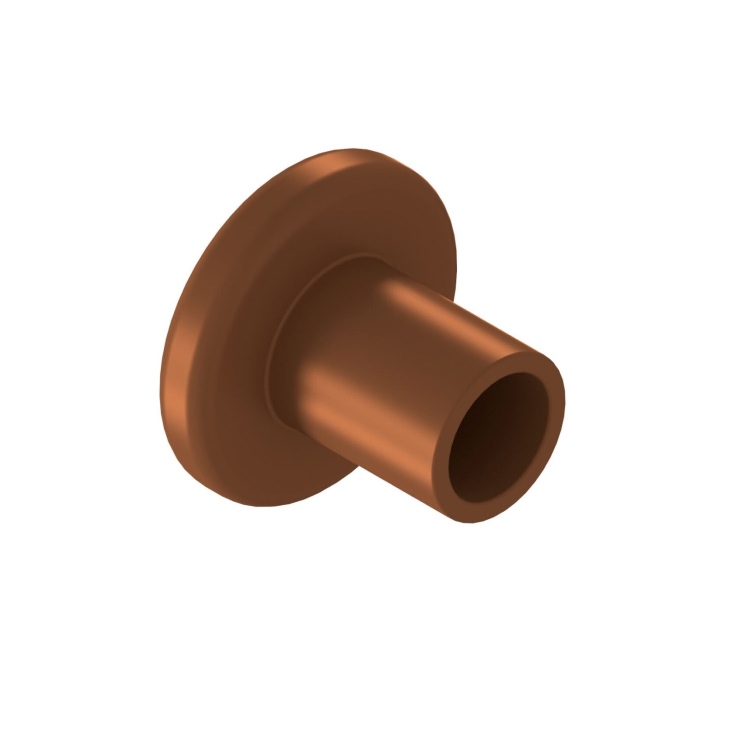

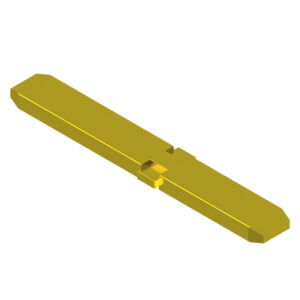

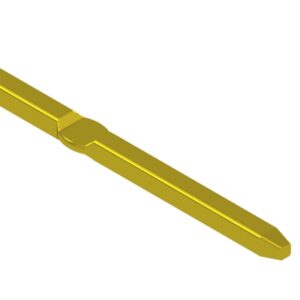

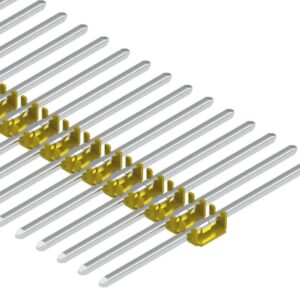

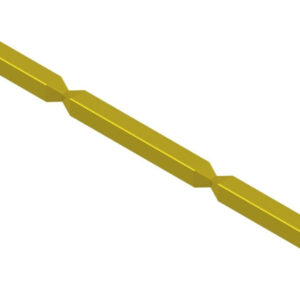

Hollow Rivet

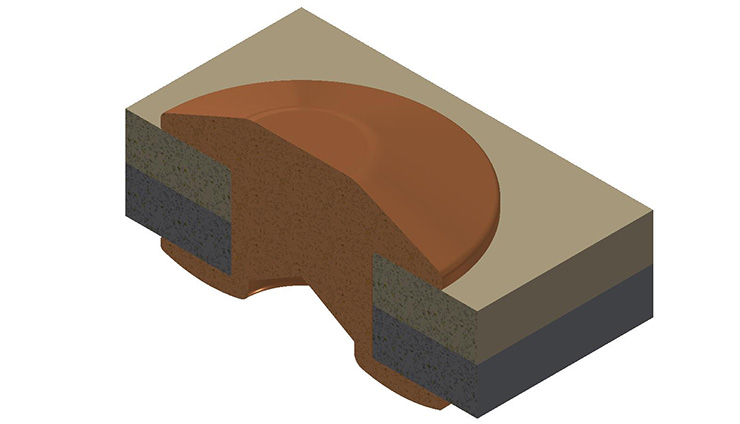

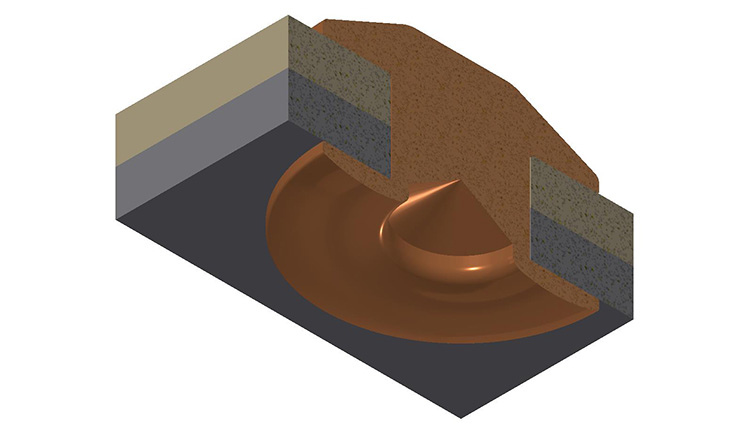

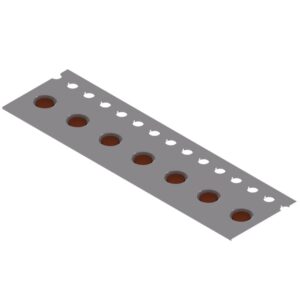

Hollow Rivets are used to fasten metal plates or molds and consist of a shaft and a head. After drilling a hole in the overlapped material, the rivet is inserted and the protruding shaft is punched to form the head, which can be round or flat. FINECS uses Cold Heading Technology instead of cutting processes to deliver high-quality, cost-effective rivets. Our hollow rivets are also applied to positive and negative terminals of in-vehicle secondary batteries and more.

Request a quote or prototype| Reference standards | φ2.0~φ8.0mm |

| Material | Aluminum, Copper & copper-related |

Main applications

Lithium-ion batteries and automotive components.

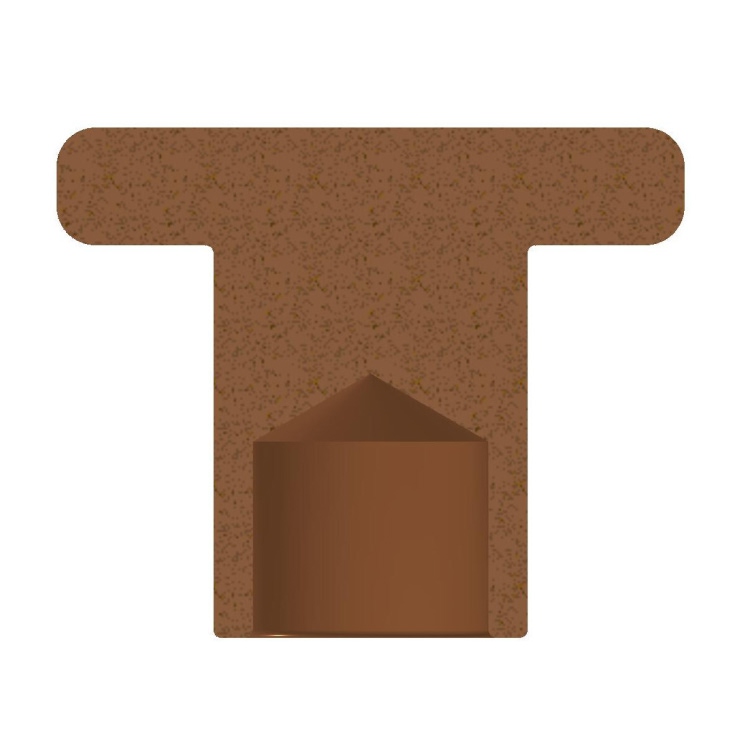

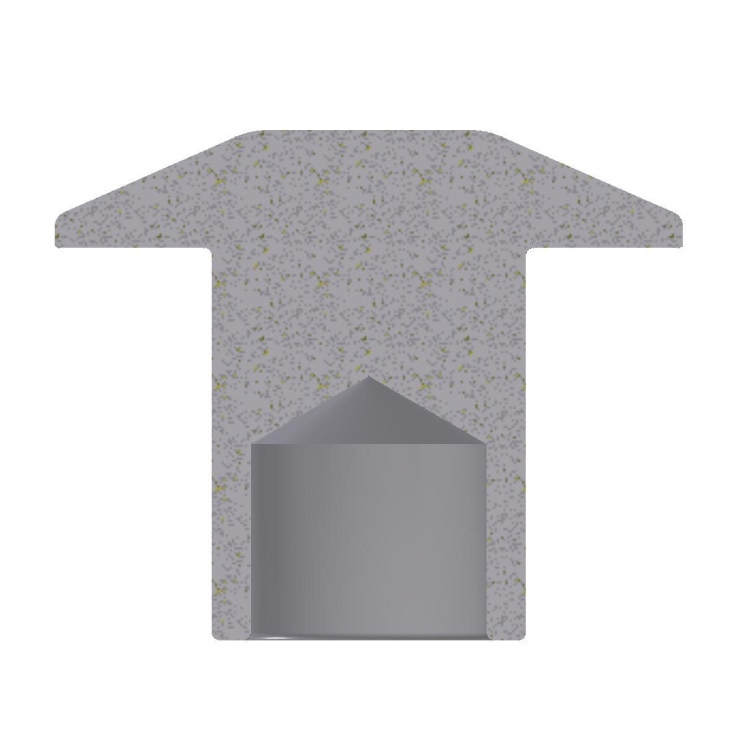

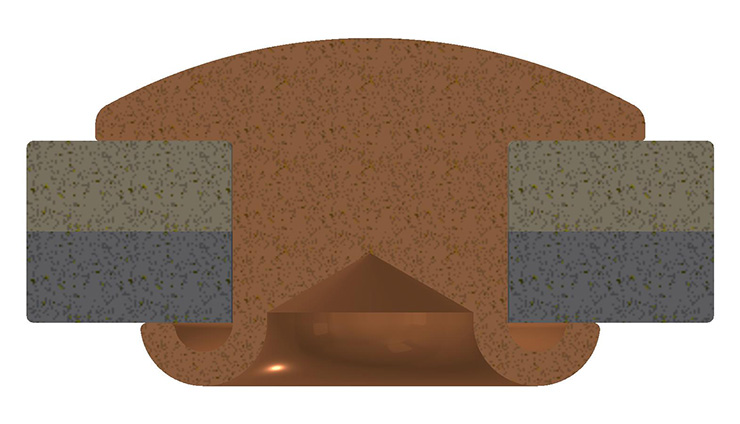

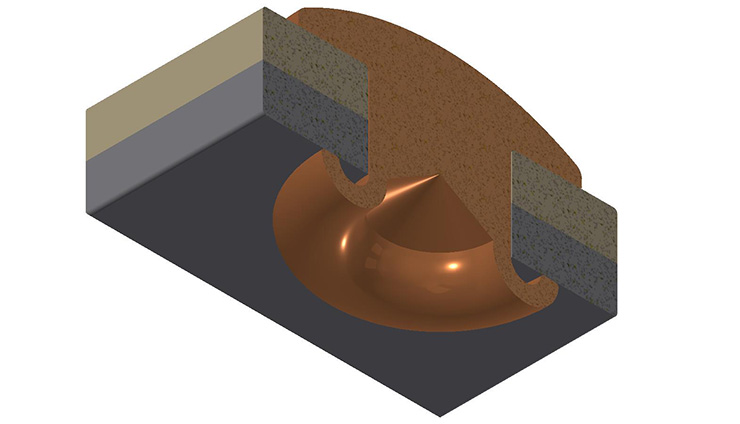

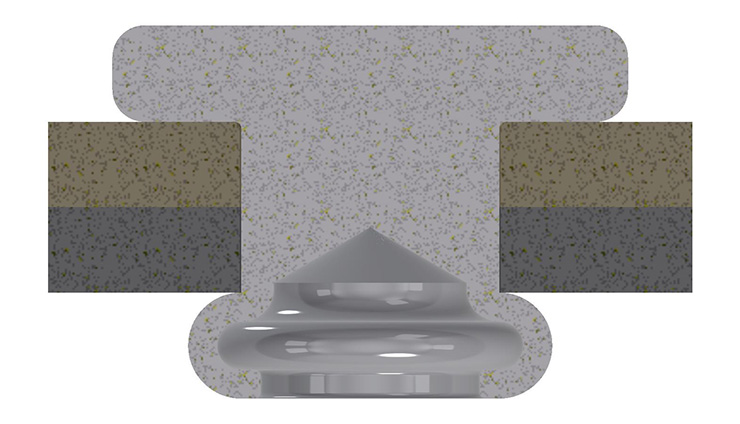

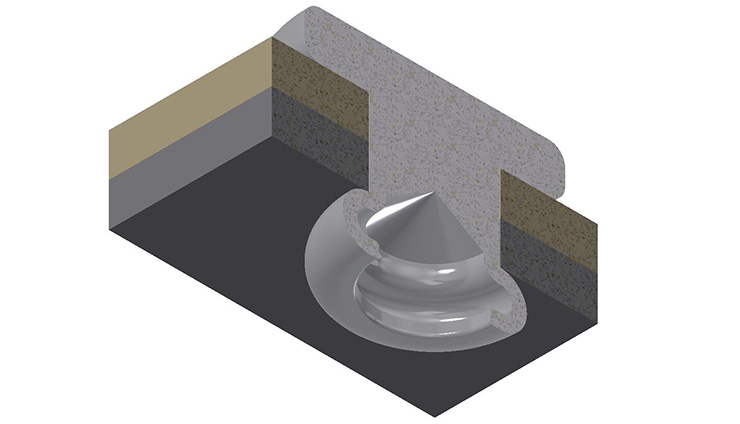

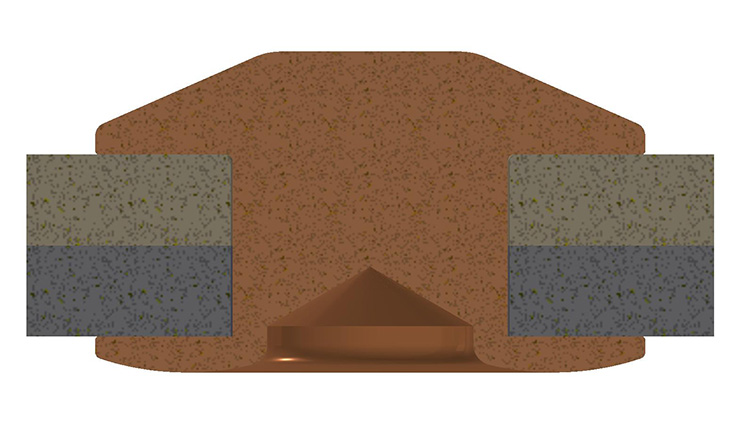

Example of hollow riveting

| example① |  |  |  |

| example② |  |  |  |

| example③ |  |  |  |

Related Links

* Specifications, materials, and other details are available upon request.

This product is manufactured by cold forging. Cold forging offers many advantages, such as lower die costs compared to press processing and lower unit processing costs than cutting, making it highly suitable for mass production.

Products with the Same Processing Method

-

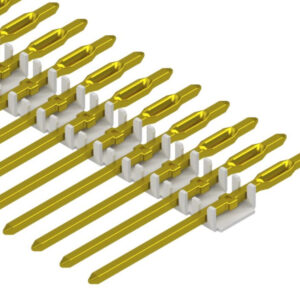

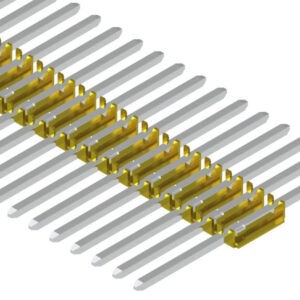

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

Deep drawn pins / cups -

Pyramidal pins -

U-shaped pins Pyramidal pins -

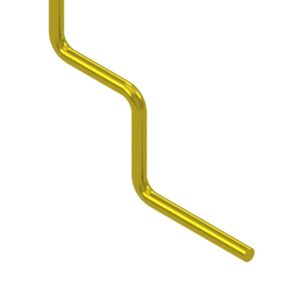

Crank-shaped pins Pyramidal pins -

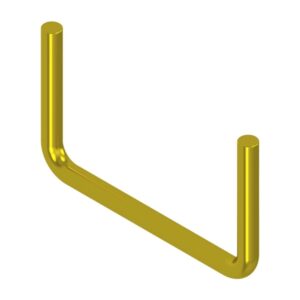

J-shaped square pins -

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

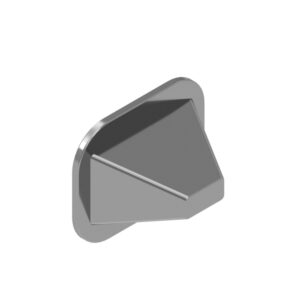

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

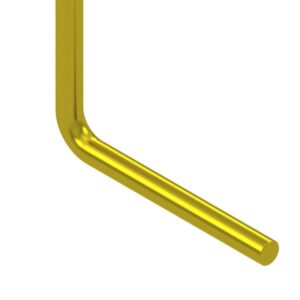

L-shaped pins (right angle) -

Double-step L-shaped pins -

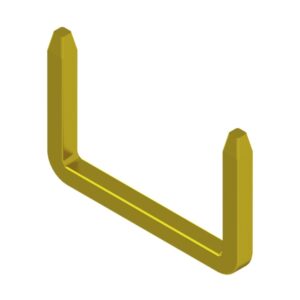

U-shaped pins -

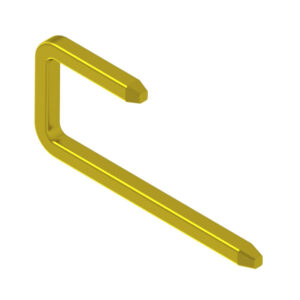

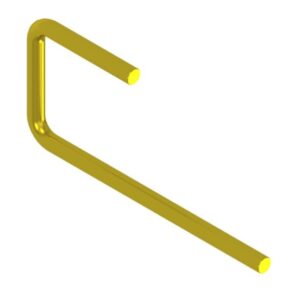

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

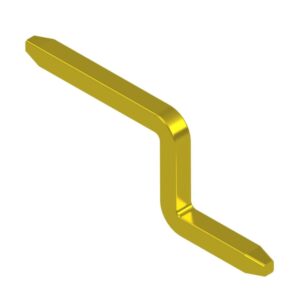

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

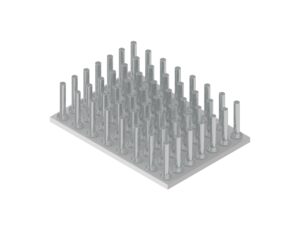

Block terminals (heat dissipation terminals and block pins) -

Terminals with solder -

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

Hollow Rivet -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay -

Electrode Terminals of Rechargeable Battery