- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

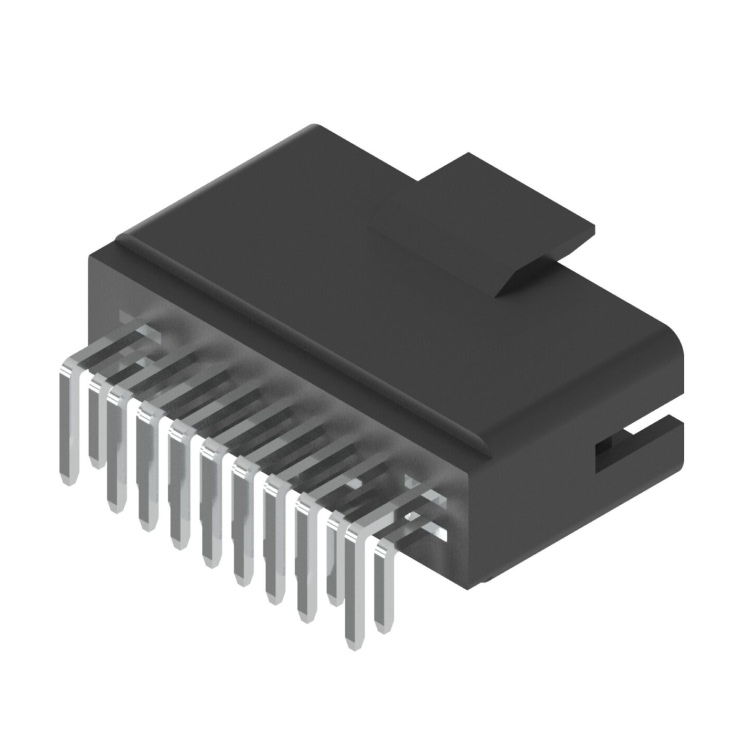

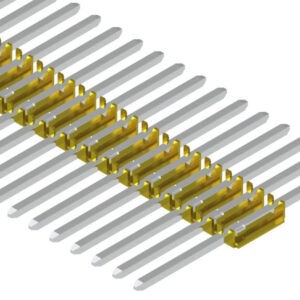

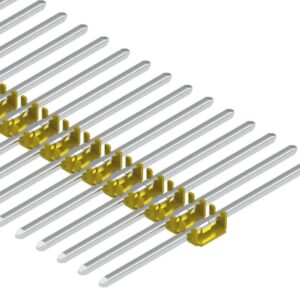

Connector Assembly with Wire Terminals

We produce connectors that use wire terminals by utilizing the know-how accumulated through years of experience in cold forging processing.

Forged bandolier terminals manufactured in-house are inserted in batches into connector housings, and assembly and inspection can be produced using a fully automated machine developed in-house.

Bulk insertion into connector housings is less expensive and can be mass-produced compared to assembly by insert molding. In addition, since we use automatic machines designed and manufactured in-house, we can accommodate a wide range of requested specifications.

Material | Forged terminals Brass, phosphor bronze, pure copper, etc. Molded products PBT, PA, PPS Liquid crystal polymer, etc. |

Related Links

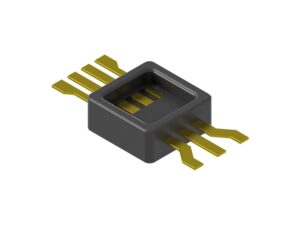

Plating

Plating on leadframes is generally Ni base + soft gold plating to enable wire bonding. For soft gold plating, partial spot plating is available to save gold.

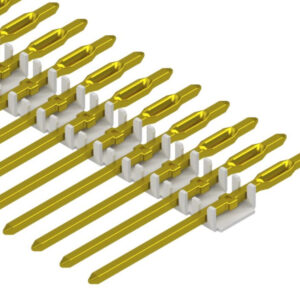

Integrated Production

FINECS has earned the high satisfaction and trust of its customers by providing a stable supply of high-quality parts through integrated production using in-house automated machines. We have developed from our forging technology, and are able to provide integrated in-house manufacturing that includes pressing, plating, forming, integrated molding, and automated assembly.

Products with the Same Shape

-

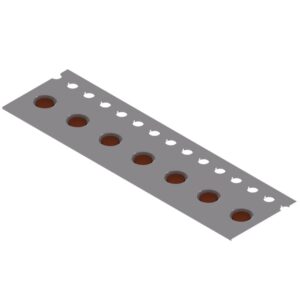

Embossed Taping (terminal pins & tiny components) -

Press-fit bandolier terminals -

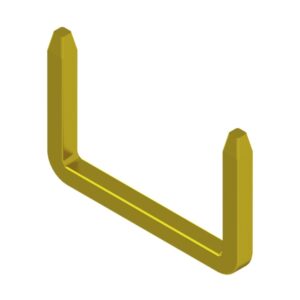

U-shaped pins Pyramidal pins -

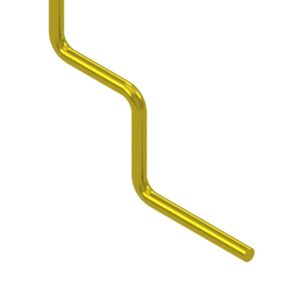

Crank-shaped pins Pyramidal pins -

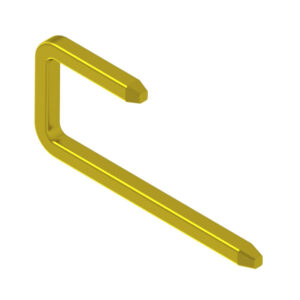

J-shaped square pins -

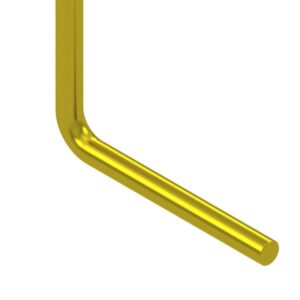

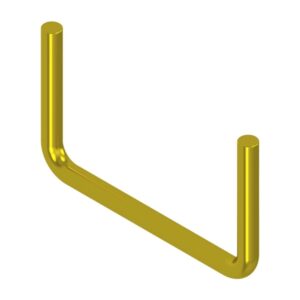

L-shaped pins Pyramidal pins and cross-shaped cross sections -

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections -

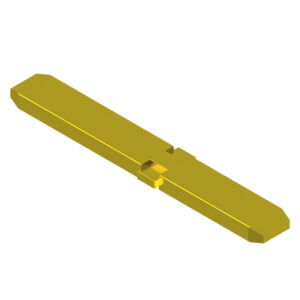

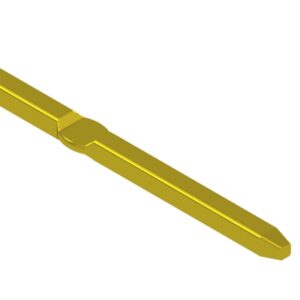

„ear-crush“ flat square with pyramid taper -

Swaged straight pins Pyramidal pins and cross-shaped cross sections -

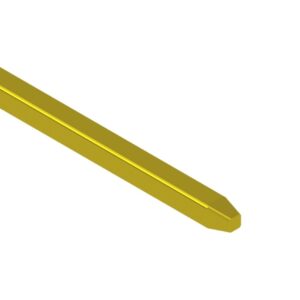

Straight pins Pyramidal pins and cross-shaped cross sections -

Partially pinched straight pins Pyramidal pins -

Partially flattened straight pins Pyramidal pins -

Straight pins Pyramidal pins -

Mid-flanged straight pins with conical tapers -

Straight pins with conical tapers and cross-shaped cross sections -

Partially pinched straight pins with conical tapers -

Partially flattened straight pins with conical tapers -

Straight pins with 4-side tapers from round wires -

Straight pins with conical tapers from round wires -

Partially flattened straight pins with round chamfers -

Partially pinched straight pins with round chamfers -

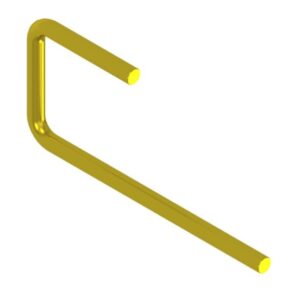

L-shaped pins (right angle) -

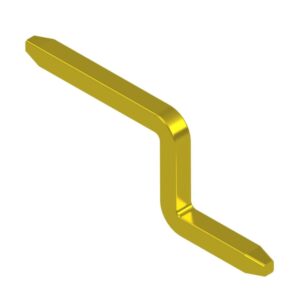

Double-step L-shaped pins -

U-shaped pins -

J-shaped round pins -

Partially flattened L-shaped pins -

High-volume Pins -

L-shaped pins Pyramidal pins -

Mid-flanged straight pins Pyramidal pins -

Mid-flanged straight pins with round chamfers -

Needle-eye square press-fit -

Bandolier terminals / pins made from square or flat square wires -

Bandolier terminals / pins made from round wires -

Crank shaped pins -

End-to-end pins / End-to-end terminals (press-fit type) -

End-to-end pins / End-to-end terminals (square type) -

End-to-end pins / End-to-end terminals (round type) -

Block terminals (heat dissipation terminals and block pins) -

Connector Assembly with Wire Terminals -

Surface Treatment (Plating) -

Terminals with solder -

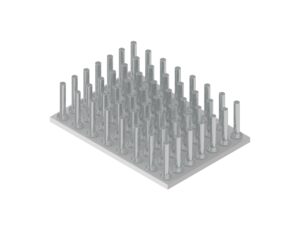

Heat radiating pins for heat sinks -

Rivet (Pin holder, Terminal holder) -

PGA Pins (Terminals for CPUs) -

Connector terminals / Connector pins -

Lead pins / Diode terminals -

Jumper pins -

Press-fit terminals (from wire) -

Substrate terminals / Post pins -

Antenna Pins -

Quartz resonator terminals (hermetic seal terminals) -

Conductive terminals -

Kovar pins (electrode pins) -

Leadless diode terminals / Dumet pins -

Brazing filler metal cut pieces (gold, silver, copper, etc.) -

Ultra-small pins, extra-fine pins, micro pins -

Plungers for Contact Probes -

Copper Pillar pin -

Copper inlay