- search by shapes

- search by processing method

- search by application

Contact Us

Feel free to contact us

for quotes

or prototype requests

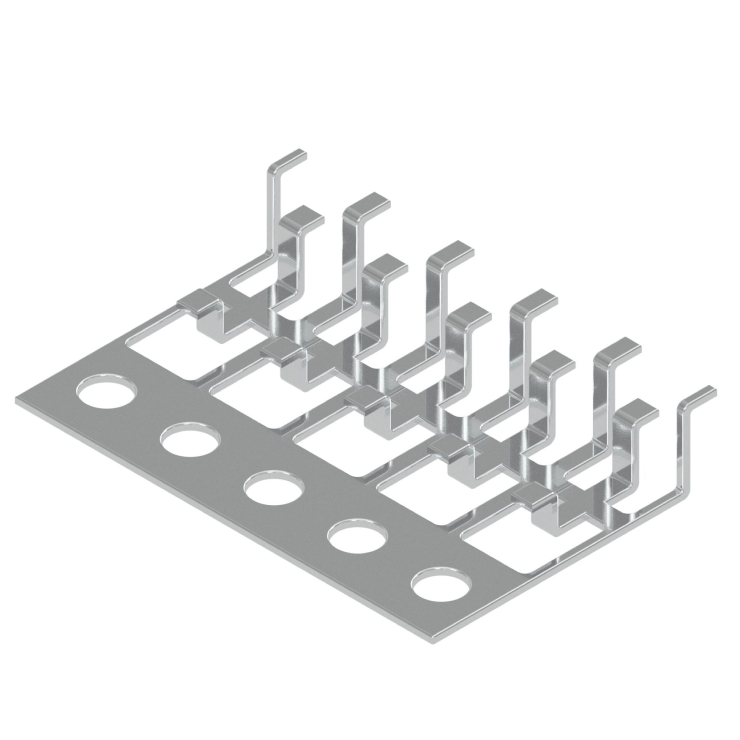

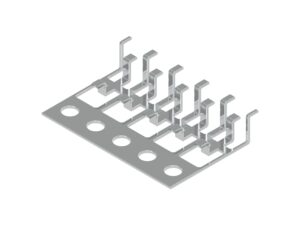

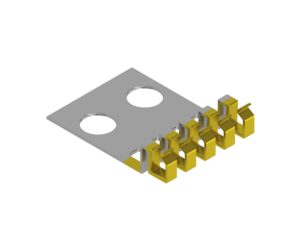

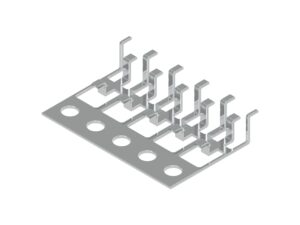

Silver plating (Ag plating) / Silver Hoop plating / press & plating

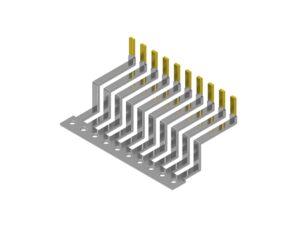

We offer connector terminals made by press-processing, like stamping, bending and more. We offer in-house made and ordered tooling.

According to your request, we provide surface treatment to improve “connectivity“ and “solder wettability” or make use of our partial plating technology to help reducing costs. In addition, we have an image inspection system installed to ensure the highest quality even for the smallest and thinnest parts.

We offer full and partial plating. Transport speed can differ depending on product design.

Main applications

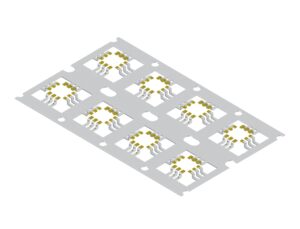

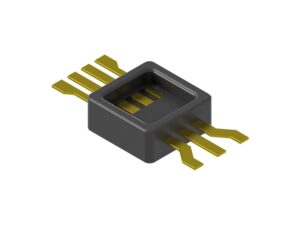

All kinds of electronic components, covering connectors or semiconductors from consumer to automotive sectors.

Our processes and supported products

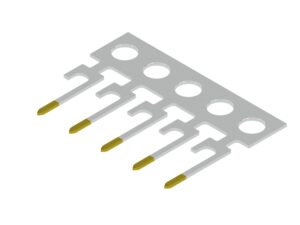

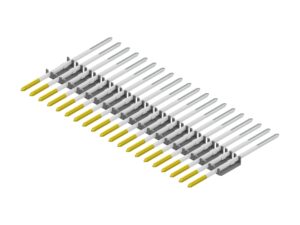

Hoop-plating (reel to reel)

At FINECS, we use hoop-plating to provide full (Au) or partial coating (Ag).

Changing to hoop-plating can help reduce costs or stabilize product quality. Please contact us if you are considering hoop-plating.

What is Silver plating?

Hoop plating is used on band-shaped products via a reel-to-reel system: The product is taken from a

reel, running through the plating line and finally wrapped up on a reel again.

This way of plating secures a stable high product quality, thus making a continuous plating cycle possible.

The reel-to-reel system further enables a high level productivity.

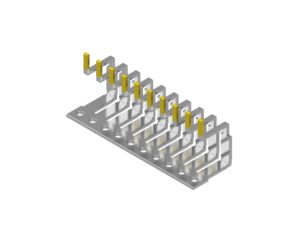

We make use of our own plating equipment for all kinds of silver plating. It is possible to handle silver plating with or without under-plating, post treatments (e.g. anti-corrosion treatment) and more.

Related Links

Products with the Same Processing Method

-

Gold-plated parts -

Partial Au plating -

Partially soft-gold plated parts・Hoop plating -

Silver plating (Ag plating) / Silver Hoop plating / press & plating -

Surface Treatment (Plating) -

Plated bandolier pins -

Outer lead frame plating -

Power semiconductor terminals (press-working and surface treatment) -

Connector terminals (press-working and surface treatment) -

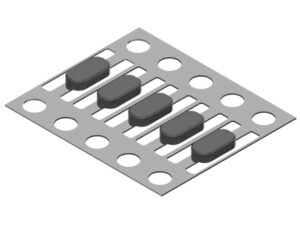

Diode terminals / connectors (press-working and surface treatment) -

Press-fit Terminals/Pins (press-working and surface treatment) -

Sensor Assemblies with Pressed Terminals