CONNECTOR

FINECS connector terminals deliver solutions that combine connection reliability with manufacturing flexibility, meeting the demands of modern product designs focused on miniaturization and high-density integration.

Our cold forging and precision pressing technologies enable complex, fine geometries while ensuring compatibility with automated assembly processes. We also provide surface treatments tailored to specific applications, optimizing conductivity and corrosion resistance.

Trusted by connector manufacturers across automotive, consumer electronics, telecommunications, and medical sectors for meeting the hight quality standards.

connector- Product List

-

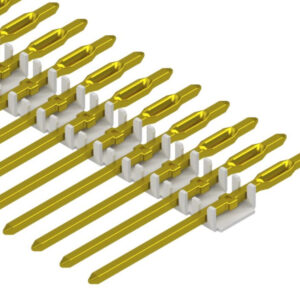

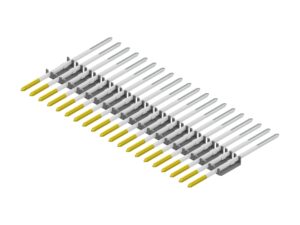

Press-fit bandolier terminals

Ensures a consistent insertion orientation for terminals

-

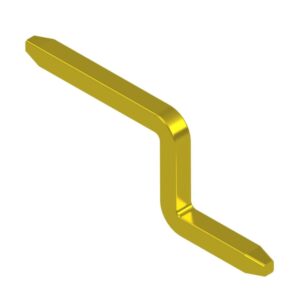

Crank-shaped pins Pyramidal pins

Pyramidal tapers on both ends with a crank bend in the middle

-

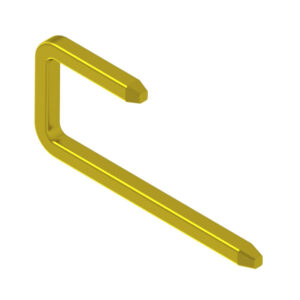

J-shaped square pins

Processed by cold forging into a shape resembling the number 7

-

L-shaped pins Pyramidal pins and cross-shaped cross sections

Flattening combined with a right-angle bend

-

Swaged L-shaped pins Pyramidal pins and cross-shaped cross sections

Connector and transformer terminals

-

„ear-crush“ flat square with pyramid taper

Flattened section that retains part of the original wire diameter.

-

Swaged straight pins Pyramidal pins and cross-shaped cross sections

Pin with one end rounded

-

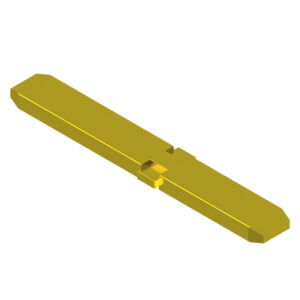

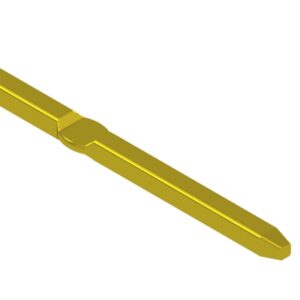

Straight pins Pyramidal pins and cross-shaped cross sections

A flattened middle section featuring diagonal protrusions

-

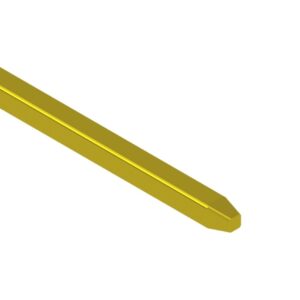

Partially pinched straight pins Pyramidal pins

Flattened in the middle while retaining part of the original wire diameter

-

Partially flattened straight pins Pyramidal pins

Pyramidal taper with a flattened section in the middle

-

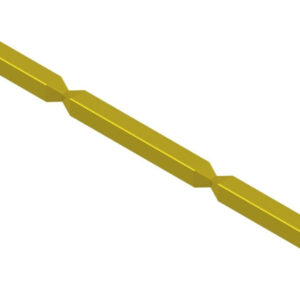

Straight pins Pyramidal pins

Square wire with pyramidal tapers on both ends

-

Mid-flanged straight pins with conical tapers

Conical tapers on both ends with a collar formed in the middle

-

Straight pins with conical tapers and cross-shaped cross sections

Flattened in the middle with protrusions extending in a cross direction

-

Partially pinched straight pins with conical tapers

Flattened in the middle while retaining part of the original wire diameter

-

Partially flattened straight pins with conical tapers

Cone-shaped taper with a flattened section in the middle

-

Straight pins with 4-side tapers from round wires

Round wire with four tapered surfaces applied to both ends

-

Straight pins with conical tapers from round wires

A component made from round wire featuring conical tapers on both ends

-

Partially flattened straight pins with round chamfers

A part with barrel-chamfered ends and a flat crimp in the middle

-

Partially pinched straight pins with round chamfers

A part with barrel-chamfered ends and a flattened crimp in the middle

-

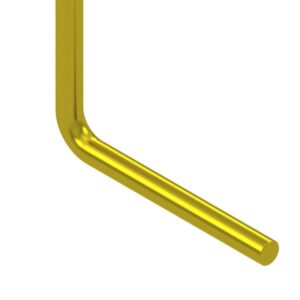

L-shaped pins (right angle)

A part with a right-angle bend in the middle

-

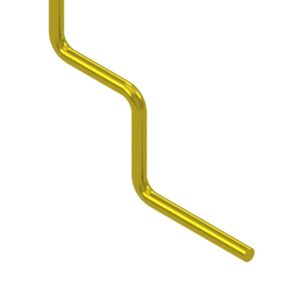

Double-step L-shaped pins

A part with two right-angle bends in the middle

-

U-shaped pins

A part with a U-shaped bend in the middle

-

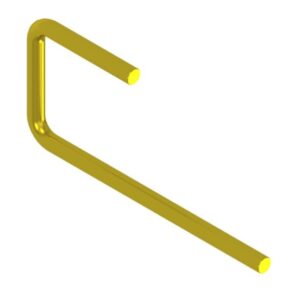

J-shaped round pins

A part with two or more bends in the middle

-

Partially flattened L-shaped pins

A part with a right-angle bend and a flat crimp in the middle

-

High-volume Pins

Single header pin with an exceptionally large flange

-

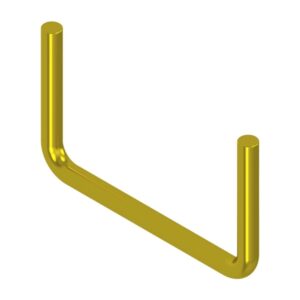

L-shaped pins Pyramidal pins

A part with tapered pyramidal ends and a right-angle bend in the middle

-

Mid-flanged straight pins Pyramidal pins

A component with tapered pyramidal ends and a flange in the middle

-

Mid-flanged straight pins with round chamfers

Featuring barrel chamfering on both ends and a flange in the middle

-

Needle-eye square press-fit

Featuring a needle-eye shaped design.

-

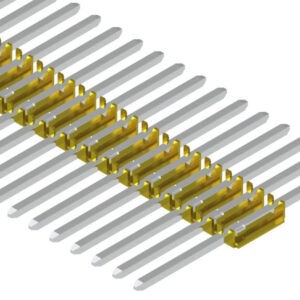

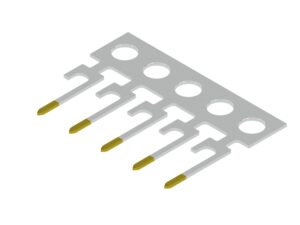

Bandolier terminals / pins made from square or flat square wires

Ensures a consistent insertion direction for terminals

-

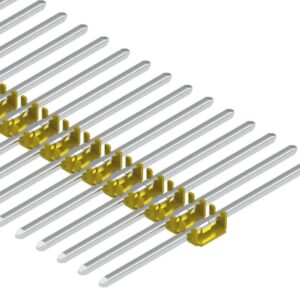

Bandolier terminals / pins made from round wires

Ensures a consistent insertion direction for terminals

-

End-to-end pins / End-to-end terminals (press-fit type)

Continuous pins with press-fit terminal shapes

-

End-to-end pins / End-to-end terminals (square type)

Delivered on reels without cutting each piece, keeping them connected

-

End-to-end pins / End-to-end terminals (round type)

Delivered on reels without cutting each piece, keeping them connected

-

Molded resin products

Injection-molded parts made from liquid crystal polymer (LCP) and other materials.

-

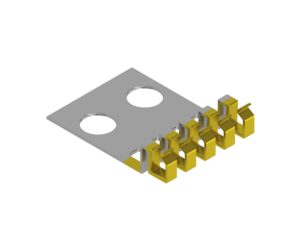

Gold-plated parts

A product offering stable corrosion resistance, excellent electrical conductivity, and superior solderability.

-

Partial Au plating

Helps reduce gold usage

-

Silver plating (Ag plating) / Silver Hoop plating / press & plating

It offers excellent electrical and thermal conductivity

-

Surface Treatment (Plating)

Offers excellent solderability, corrosion resistance, and electrical conductivity

-

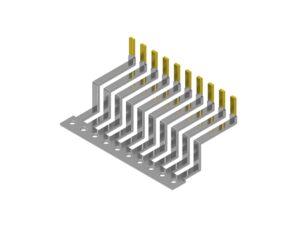

Plated bandolier pins

Continuous plating of pins embedded in a carrier produced by progressive press processing

-

Connector terminals / Connector pins

Various Shapes Achieved Through Our Proprietary Cold Forging and Header Processing Technologies

-

Press-fit terminals (from wire)

Eliminates the soldering process and contributes to reducing environmental impact.

-

Quartz resonator terminals (hermetic seal terminals)

Features hermetic sealing

-

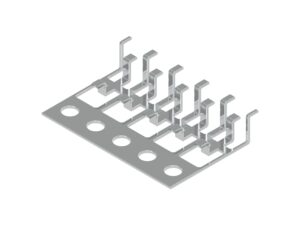

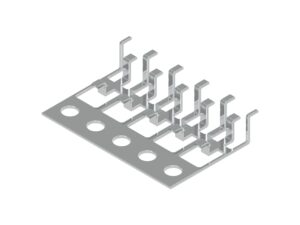

Connector terminals (press-working and surface treatment)

Manufactured through processes such as punching and bending.

-

Diode terminals / connectors (press-working and surface treatment)

Manufactured through processes such as punching and bending.

-

Press-fit Terminals/Pins (press-working and surface treatment)

Enables cost reduction and lower environmental impact.