As a globally expanding manufacturing company, we strive to develop and provide environmentally conscious products to meet the expectations of our customers around the world through our products, while at the same time contributing to the preservation of the global environment and the formation of a recycling-oriented society. We strive to reduce the environmental impact of our products, beginning from their production throughout their life cycles. Through the use of our products, we support our customers' ISO14001 activities and thus strive to realize a society with low environmental impact.

Introduction of Environment-friendly Products

We propose to reduce the environmental burden by replacing cutting and pressing processes by our header-technology based press-fit terminals, terminal pins, and numerous other parts. We also offer environment protecting products that are manufactured by our integrated production system for various electronic mechanical components (composite products).

index

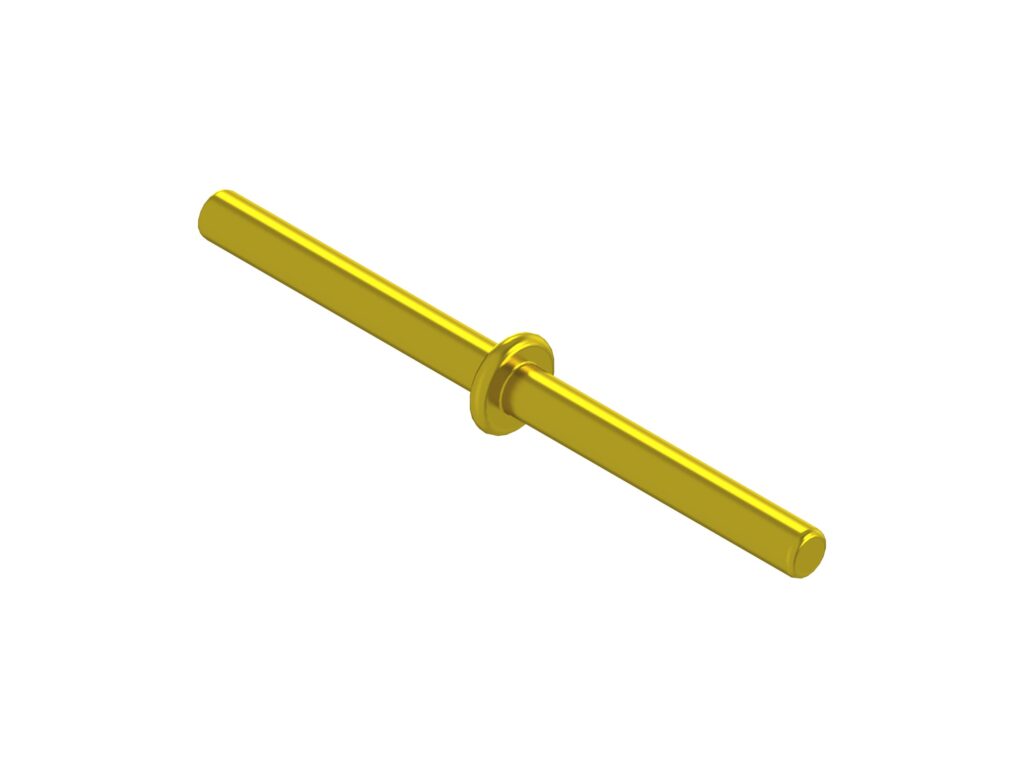

- Press-fit terminal pin

- Various wire rod terminal pins, various crimp parts

- Electrical mechanical parts (press-fit assemblies, insert molded products)

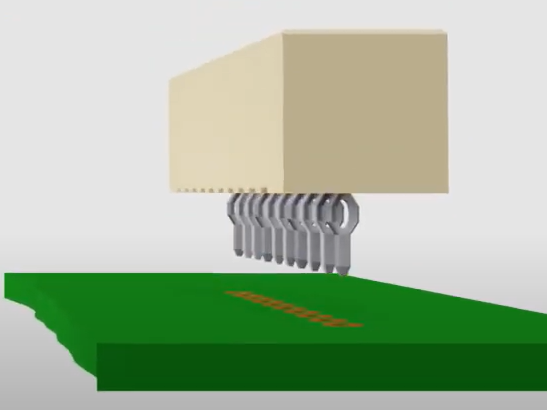

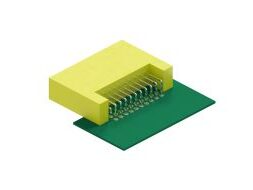

Environmental product 1: Press-fit terminal pin

The press-fit terminal can be attached to the board by simple insertion, eliminating the need for solder, a mounting or a reflow process, which leads to simplifying the whole assembling process. This makes it possible to reduce the amount of heat (electricity) energy, which would be consumed during the solder dipping and reflow process, resulting in significant costs reduction and the establishment of an environmentally friendly manufacturing process.

Benefits of introduction (environment, cost, quality)

- No requirement for soldering processes, solder dipping processes and reflow processes.

- Significant reduction of energy consumption and manufacturing costs.

- A complete set of initial equipment costs for the solder application process is not required. Simplification of the process is also realized.

- Eliminate defects related to solder joints

- Promotion of lead-free processing

- Removing thermal damage to each component on the board during the reflow and solder dip process.

- Supporting your company's ISO14001 activities (manufacturing with low environmental impact)

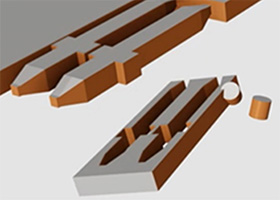

Environmental products 2: Various wire rod terminal pins, various crimp parts

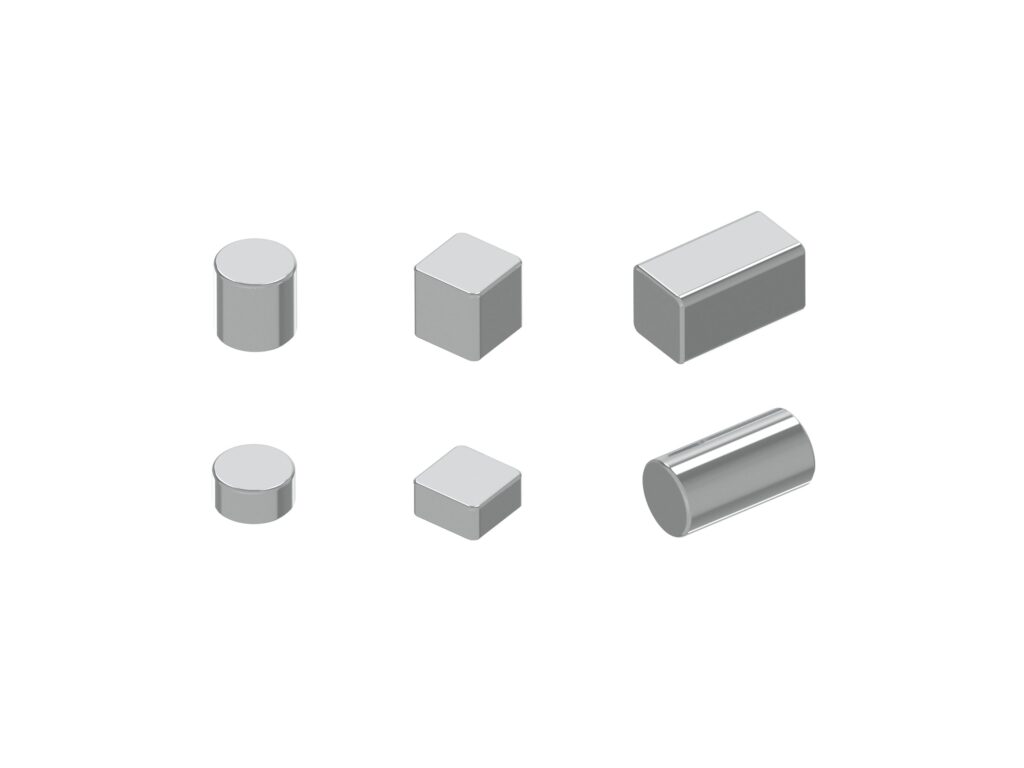

Header-processed products from metal wires can significantly reduce initial die costs compared to pressing from metal strips. In addition, this product does not generate punching debris and cutting debris that are generated during press working. It also reduces raw material costs and has a relatively low environmental impact.

Terminals from metal strips are scratched.

Crimping (header)-processed products are eco-friendly, do not cause scraps, significantly reduce material and initial die costs.

Examples of products for environmentally conscious wire rod terminals and crimped parts

Metal wires are aligned and attached onto a metal band. Used as electrical contacts for connectors, etc.

Copper inlay, heat dissipation terminal, block terminal

Used for heat radiation of various substrates and semiconductors.

Eco-friendly product that drastically reduces initial die costs and generates no scraps compared to pressed terminals.

Reduction of costs and environmental impact by replacing cutting

Shapes and products that are advantageous over pressed items in terms of material costs, environmental burden, and quality.

Benefits of introduction (environment, cost, quality)

- Material costs can be reduced (no debris)

- The volume of used metallic materials is small, enabling the creation of eco-friendly products.

Although cheaper in production, no loss of quality.

- The volume of used metallic materials is small, enabling the creation of eco-friendly products.

- The initial die / tooling costs can be drastically reduced. The size of the die itself is also significantly smaller and eco-friendly.

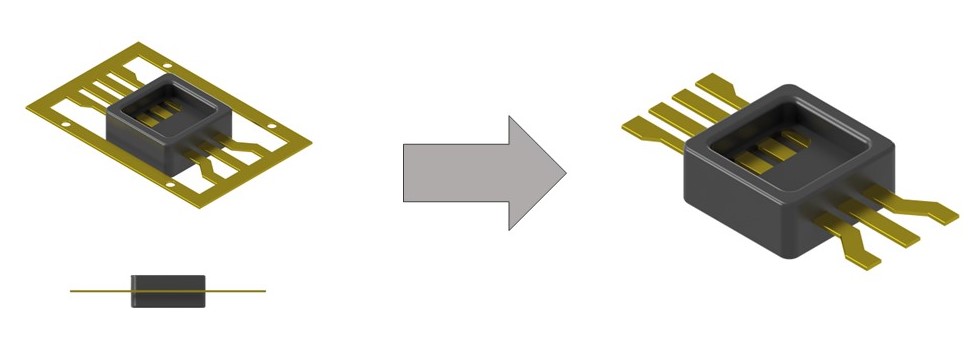

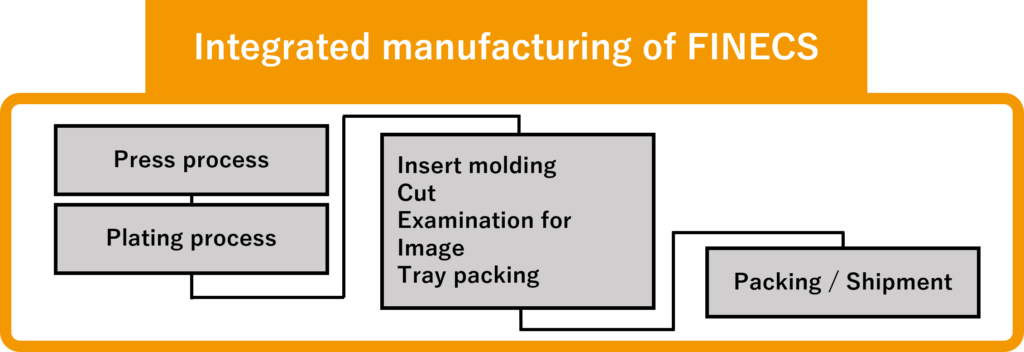

Environmental products 3: Electro-mechanical parts (press-fit assemblies, insert molded products)

We have an integrated manufacturing system installed in our plants, including press working, plating, insert forming, and automatic assembly, where we create our products through the combination of multiple processing methods.

As a result, we can significantly reduce the costs that would occur by transporting our products to subcontractors. Also the limitation of transportation times, and CO2 generation during transportation, helps us contributing to a global environmental protection.

Benefits of introduction (environment, cost, quality)

- Since the pre-and post-processes are close to each other in internal integrated production, feedback of quality can be quickly realized, the quality itself can be improved, costs can be reduced, and at the same time, in-process defects can be largely prevented.

- In-house integrated production reduces transportation costs to subcontractors, transportation time, and CO2 emissions.

- Reduction of packaging material costs related to product movement and transportation.

FINECS’ ISO14001 Efforts

In August 2008, we obtained the ISO14001 certification, the international standard for environmental management systems.

Product Assessment

We conduct product assessments to reduce our environmental impact.

In product assessment, we develop and manufacture products after confirming the absence of substances of concern, and confirming energy- and resource-saving designs at each stage of the manufacturing process, the process design, and the packaging specification examination.

Introduction to FINECS Energy Conservation and Energy Creation Project "ELEC50"

The FINECS Group is promoting the Environmental Project "ELEC50" with the aim of protecting the global environment and forming a recycling-oriented society. We are aiming to reduce electricity costs by half, combining energy conservation and energy creation. We are enhancing our corporate competitiveness and at the same time promoting environmentally conscious manufacturing.

Our goal is to promote global environmental conservation by encouraging our customers to use our products.

Realize energy savings by utilizing the characteristics of groundwater with constant temperature