Cu/Al composite electrode terminals TANSEZ terminals

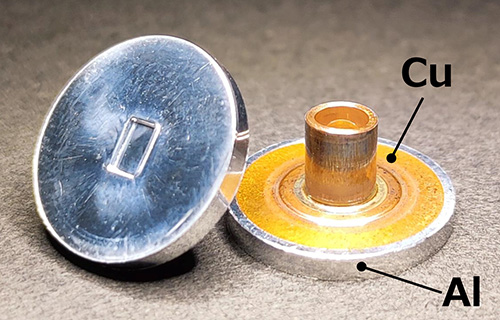

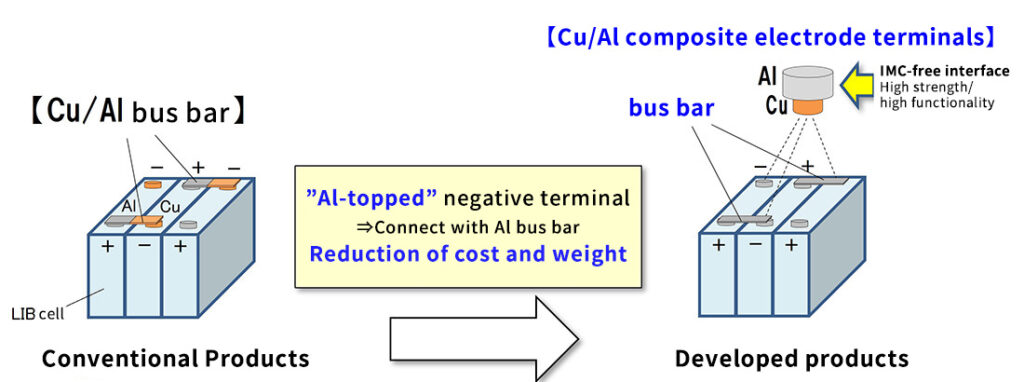

In this development, we have combined the low-temperature forge welding method, which is virtually IMC-free for joining dissimilar materials, with high-precision double-action die technology to develop innovative Cu/Al composite electrode terminals that eliminate the need for Cu/Al bus bars in lithium-ion batteries.

Development Background

With the rapid progress of electric drive of mobility, lithium-ion battery (LIB) cells, which are the core element of mobility, usually use Al for the positive terminal and Cu for the negative terminal. Therefore, Cu/Al dissimilar material bonding is required for series connection of LIB cells, but this material combination easily forms a weak intermetallic compound (IMC), making practical welding impossible. For this reason, expensive Cu/Al clad bus bars are generally used to connect these electrode terminals. In order to reduce costs and improve functionality and reliability as electrical components, there is a strong market need for Cu/Al composite electrode terminals, in which the Cu negative electrode terminal is Al-topped and can be connected with an Al bus bar.

What is a TANSEZ terminal?

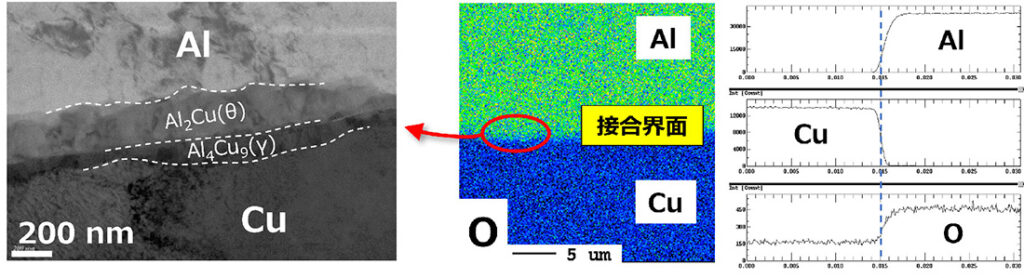

The low-temperature forge welding method diffuses and bonds metals directly at low temperatures and in a short time without using flux or insert materials by a large deformation at the bonding interface, and is a "virtually IMC-free" method that can render the reaction layer harmless for dissimilar metals. This is a "virtually IMC-free" bonding method that can render the reaction layer harmless for dissimilar metals. It is a highly productive multi-material technology that enables forming and bonding to be carried out in an instant. Another major feature not found in conventional processes is that the robustness of the joint can be controlled by the pressure drop ratio, which is the ratio of the wall thicknesses before and after the joint.

Key Development Technologies

- Cold forge welding "Bonding & forming in an instant" Cu/Al dissimilar materials that are difficult to weld togerher.

- The reaction layer(IMC) at the brittle Cu/Al bonding interface is made ultra-thin and harmless. → High strength /high conductivity interface.

- "Zero loss" by using up all materials →"Contribution to SDG's"

We provide solutions tailored to your specific workpiece.

Wondering if FINESERT® suits your application?

If you have any questions regarding the consideration of introducing the continuous pin insertion machine “FINESERT®,” please feel free to contact us.

For more information about FINECS terminals and pins, please visit this page as well.

We introduce technical information on our high-quality products developed through proprietary backed methods by over 50 years of manufacturing experience.