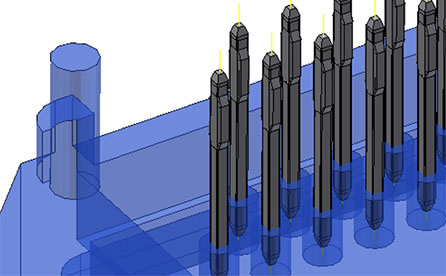

Pin Insertion Machine FINESERT®

Continuous operation reduces time

Our high-quality continuous pins can be automatically inserted into your workpieces.

We will provide you with a set of continuous pins.

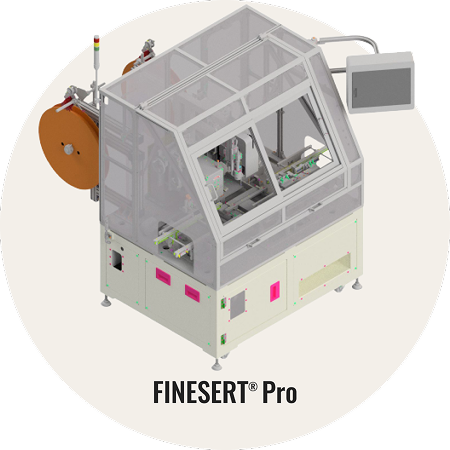

FINESERT® Pro

Can be customized for each customer

Feature

Cam drive insertion head

Short insertion cycles. Achieves high-precision repeated insertion height.

Variation of customized unit

Custom selection of "straight pins" and "L-bending pins" for the insertion unit. For backup, the "cradle method" and "anvil method" can be selected.

Available terminal shape

Rectangular wire, Press fit, Round wire, Custom shape

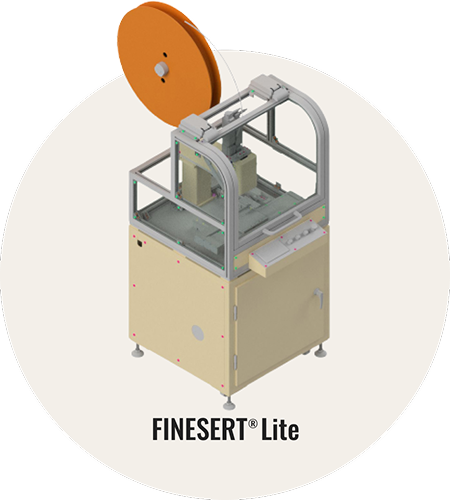

FINESERT® Lite

Pursuit of economic efficiency by narrowing down functions

Feature

Electric cylinder insertion head

The insertion height adjustment can be set with the numerical value input. Height adjustment is no longer necessary when switching models with different pin lengths.

Electric cylinder insertion head

The feed length of the pin can be set by numerical entry.

Switching between pin types with different lengths is easier.

Available terminal shape

Rectangular wire, Round wire, Custom shape

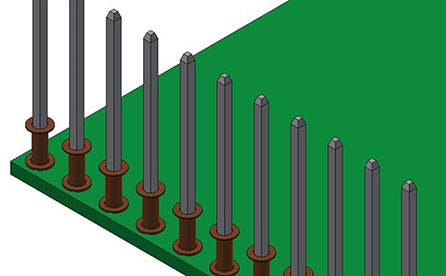

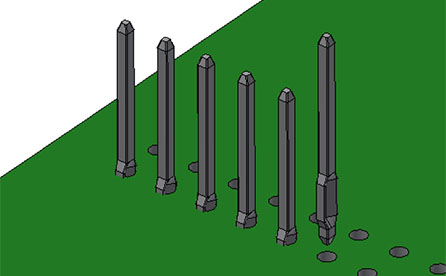

Practical case

Products formed by cold heading from metal wire can significantly reduce initial die costs compared with press processing from metal strip. In addition, because no punching scrap or machining chips are generated as in press processing, raw material costs can be reduced and the environmental impact is relatively lower.

We provide solutions tailored to your specific workpiece.

Wondering if FINESERT® suits your application?

If you have any questions regarding the consideration of introducing the continuous pin insertion machine “FINESERT®,” please feel free to contact us.

For more information about FINECS terminals and pins, please visit this page as well.

We introduce technical information on our high-quality products developed through proprietary methods backed by over 50 years of manufacturing experience.