Copper pillar pins

What is Copper Pillar Pin?

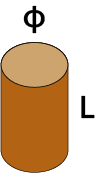

Copper pillar pins are cylindrical copper alloy components that are ideal for circuit connections in advanced packages.

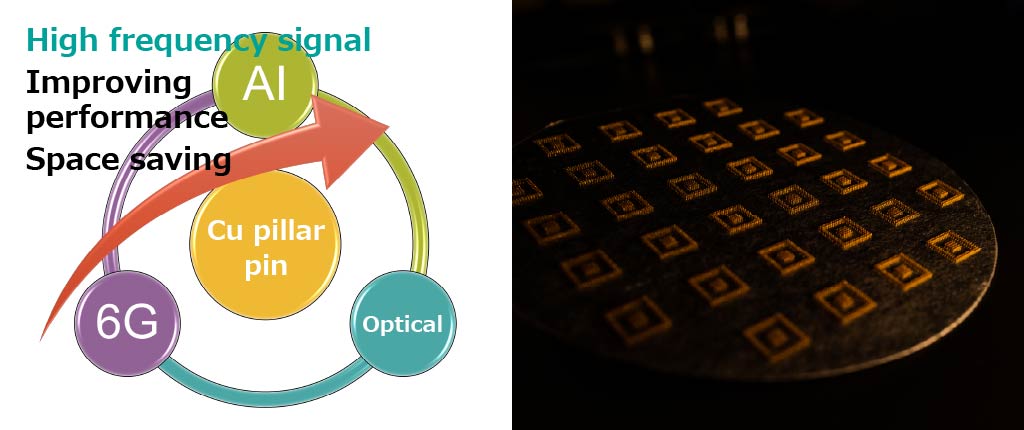

The electronics industry is advancing with the expansion of generative AI, transition to 6G, and the spread of optical communication circuits, leading to increasingly high-frequency circuit signals. FINECS copper pillar pins contribute to further circuit performance improvement and space-saving required for high-frequency signals.

Benefits of adopting copper pillar pins(Comparison to conventional technology)

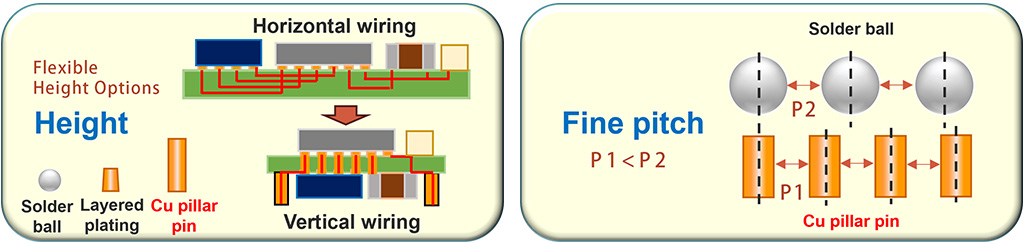

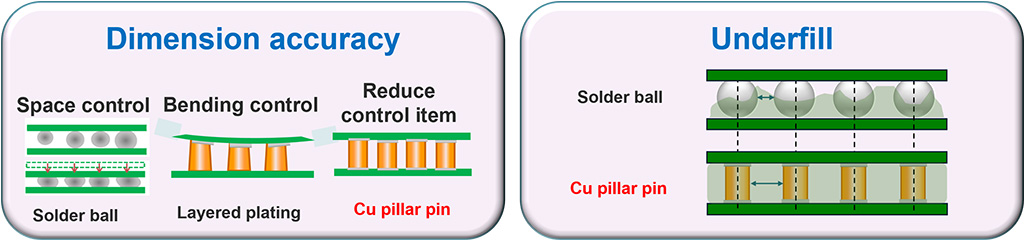

Traditional technologies used for circuit connections in semiconductor packages include solder balls and layered plating.

Space saved connection

In the market, vertical wiring is preferred rather than horizontal wiring to shorten wiring length, and copper pillar pins with height flexibility are very suitable for vertical wiring.

Moreover, solder balls are spherical, but copper pillar pins are cylindrical, allowing for a higher aspect ratio, advantageous for narrow-pitch connections.

From these points, it can be said that copper pillar pins have features suitable for space-saving wiring in advanced packaging.

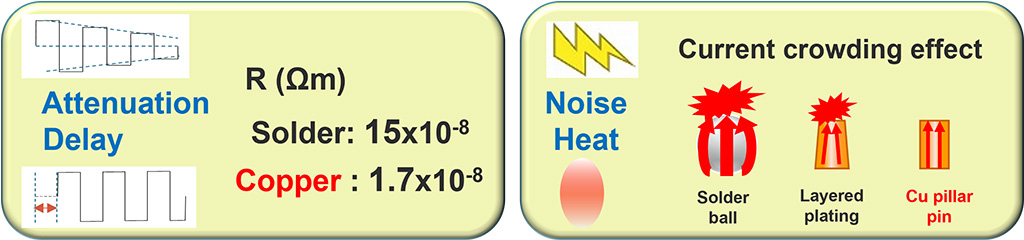

Electrical performance

Compared to solder materials, copper alloys have higher conductivity and lower resistance.

Lower resistance leads to improving signal attenuation and delay in circuits, and this performance will be increasingly demanded as signal frequencies rise.

Additionally, copper pillar pins are performance superior in terms of suppressing noise generation, heat generation, and heat dissipation due to their low resistance and reduced impact from current crowding.

Process control

Solder balls require management of space and substrate warping due to dimensional variations and collapse during melting.

Layered plating, which takes time for plating growth, is prone to dimensional variations, necessitating dimensional management to prevent substrate warping during connection.

Copper pillar pins have excellent dimensional accuracy, reducing management items in terms of space and substrate warping.

Furthermore, the underfill process of filling resin in the gap between components and the substrate is easier to manage with copper pillar pins than with ball shapes.

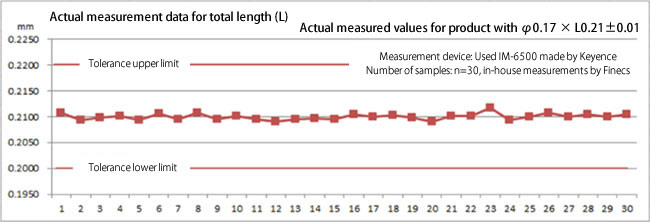

L dimension measurement data *Stable within ±5μm

Applications of copper pillar pins

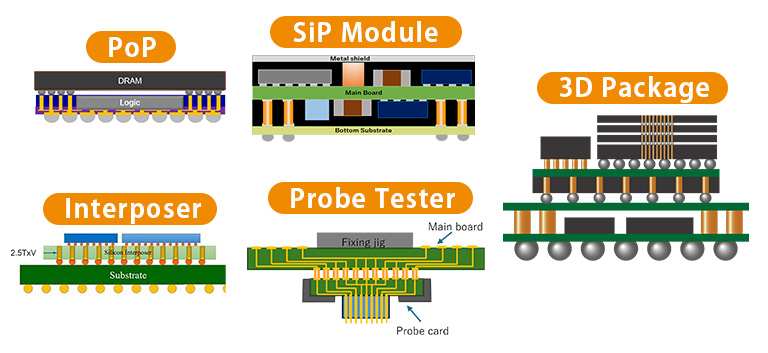

Their applications include PoP, interposers, SiP modules, 3D packages, and probe tester boards, where copper pillars are anticipated to achieve miniaturization and performance enhancement.

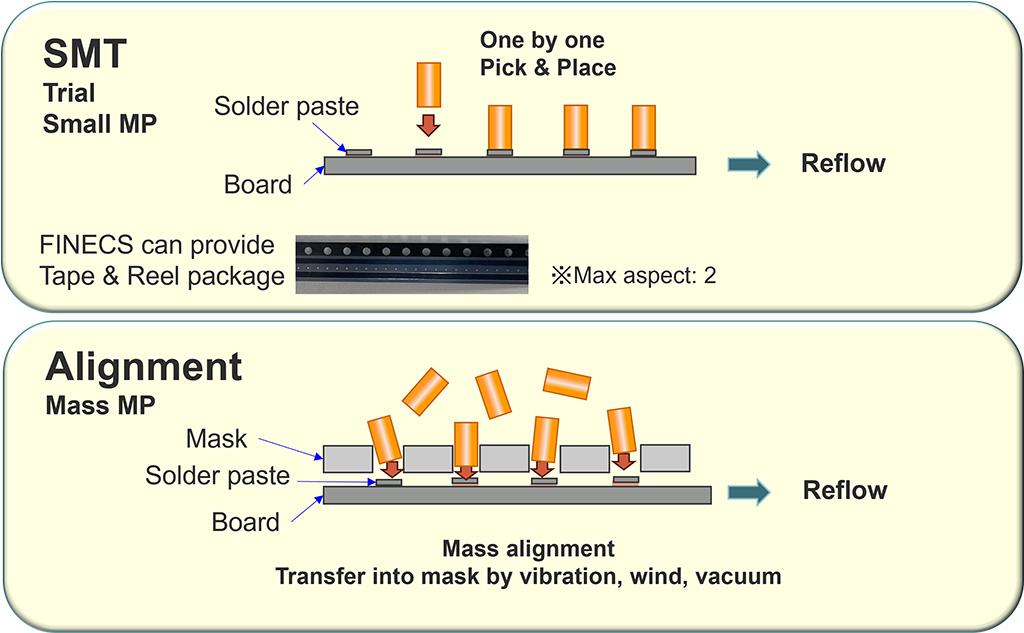

Alignment and mounting

Copper pillar pins packaged in embossed tape can be mounted on a substrate using a surface mount machine and fixed by reflow implementation. For mass production, it is practical to use alignment machines that align copper pillar pins with machine heads. On a substrate coated with solder paste, a mask for pin insertion can be used to align a large number of copper pillar pins at once through vibration or wind.

Depending on the material, the content of constituent elements varies, affecting the coefficient of thermal expansion, thermal conductivity, and electrical conductivity. In terms of conductivity, we offer materials with 99% IACS or higher, contributing to improved heat dissipation effects, EMI noise reduction, and signal quality improvement.

| Material code | Element (%) | CTE (x10-⁶K) | Thermal conductivity (W/mK) | Conductivity (%IACS) | Specific gravity |

| F0 | Cu:other Sn:5.5~7.0 P:0.03~0.35 | 18 | 65 | 14 | 8.84 |

| F7 | Cu Fe Zn:0.13 P:0.04 | 17.4 | 260 | 60-70 | 8.9 |

| FE | Cu Zn:0.2 Mg:0.15 | 17.5 | 300-330 | 76-83 | 8.9 |

| F9 | Cu Sn:0.15 | 17.3 | 360 | 82 | 8.9 |

| FB | Cu:99.99% Other | 17.7 | 391 | >99% | 8.9 |

Copper pillar pins standard specification

This list of standard specifications for copper pillars is product specifications that FINECS holds in stock for providing prototypes to customers, allowing for quick delivery to customers. There is an inquiry form on the FINECS website, so please feel free to use it.

Download the Standard Specifications for Copper Pillar Pins Here >

Popular size and available range

It shows the possible range of wire diameter and height length. For items not on the prototype standard product list, please refer to this as well, and if you inform us of your desired size or material code, we will accommodate your request.

| Type | Shape | Diameter/Size (Φ) Unit: mm | Pitch | Length (L) Unit: mm |

| Round |  | φ2 | >2.2mm | 1.60~6.0 |

| φ1.5 | >1.7mm | 1.20~6.0 | ||

| φ1 | >1.2mm | 0.80~6.0 | ||

| φ0.8 | >1mm | 0.64~6.0 | ||

| φ0.4 | 500-600um | 0.32~5.0 | ||

| φ0.25 | 350-500um | 0.20~5.0 | ||

| φ0.2 | 300-400um | 0.16~4.0 | ||

| φ0.15 | 275-350um | 0.12~3.0 | ||

| φ0.12 | 220-300um | 0.10~2.0 | ||

| φ0.09 | 150-220um | 0.10~1.0 | ||

| φ0.06 | 120-150um | 0.10~1.0 | ||

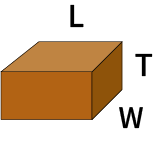

| Type | Shape | Diameter/Size (Φ□) Unit: mm | Pitch | Length (L) Unit: mm |

| Square |  | □W0.2*T0.2 | N/A | 0.20~1.0 |

| □W0.33*T0.23 | 0.33~5.0 | |||

| □W0.4*T0.3 | 0.40~5.0 | |||

| □W0.4*T0.4 | 0.40~5.0 | |||

| □W0.35*T0.35 | 0.35~5.0 | |||

| □W0.7*T0.3 | 0.70~6.0 | |||

| □W0.8*T0.0.5 | 0.80~6.0 |

Solutions Using Copper Pillar Module

As an agent and manufacturer handling FINECS pins, they can propose solutions for implementation applications. Additionally, C-TECH can propose methods for fixing pins on temporal substrates as pin array modules and supply pin array modules by herself.

Copper pillar pins are realized for customer use at mass production levels through alignment technology and pin array module methods by equipment manufacturers.