Advantages of cold forging

Advantages of cold forging

Comparison with press working

>Forging and pressure forming processes do not cause material loss because material punching is not performed.

>Forging and press working are inexpensive in die cost, etc.

Comparison with cutting

>Forging and rolling processes do not shave the material, so there is no material loss.

>Forging and press working can be produced in large quantities at high speed.

Comparison between press working and cutting work and cold heading working (cold header processing)

Cold heading using metal wire rods enables cost reduction compared with press working and cutting work.

A comparison table for each processing method is prepared below. It is important to select the machining method according to the application.

When considering the procurement of pins and terminals, please consider using cold heading.

Demerits of cold forging

- It is difficult to machine complicated shapes.

- It takes a lot of preparation time (set-up time) of the machining equipment, so it is not suitable for the machining of small lots.

Forging and Pressing

In the plastic working of metallic materials, "forging" and "pressure forming" are used in the same sense as forging, pressure forming, etc. "Forging" is used to obtain the desired shape by applying a large pressure to the material. In addition to obtaining the desired shape, the term "forging" is often used when it is meaningful to increase the strength in combination with the shape deformation, and "press forming" is often referred to as header forming. This is a machining method that is mainly used to obtain the shape like the head of a screw (head).

As mentioned above, the press forming and forging are used in almost the same sense. However, the method of deforming the material by applying pressure from the lateral direction is the press forming method, and the method of deforming the material by applying pressure in the vertical direction is generally the forging method.

Cold heading |  Press working |  Cutting | |

| Initial cost of the mold | 〇 Several 0.1 million yen | ✕ Some millions | ー |

| Mold maintenance costs | 〇 Maintenance Small Parts | ✕ Maintenance Many parts | ー |

| Material loss | 〇 Almost no material loss | △ Some material loss | ✕ Be so many |

| Unit price for mass production | 〇 Capable of producing 1M+ pcs/month | 〇 Suitable for mass production | ✕ Be very expensive |

| Productivity | 〇 Low cost | 〇 Low cost | ✕ Low production utilization rate |

| Exposure of base metal when using pre-plated material | 〇 Tip only | ✕ The punched surface is exposed. | ✕ Not available |

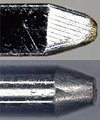

| Tip shape |  The angle and dimensions of R can be changed. |  Two-sided R | 2-side and 4-side R |

| Other characteristics | Easy-to-process round pinbandolierallows pitch-changing the entire length of the pin. This only adjusts the length and eliminates the need for a new mold. | Necessary to manufacture a new die for changing the terminal pitch and overall length. Round pin machining is difficult. | Only round pins can be processed |

| Another name | Cold forging Cold header processing Forming process | Stamping | ー |