Copper inlay (Cu inlay)

This product is manufactured and sold by FINECS.

We handle monthly quantities from 10,000 to multiple 100,000,000 pcs.

Product features

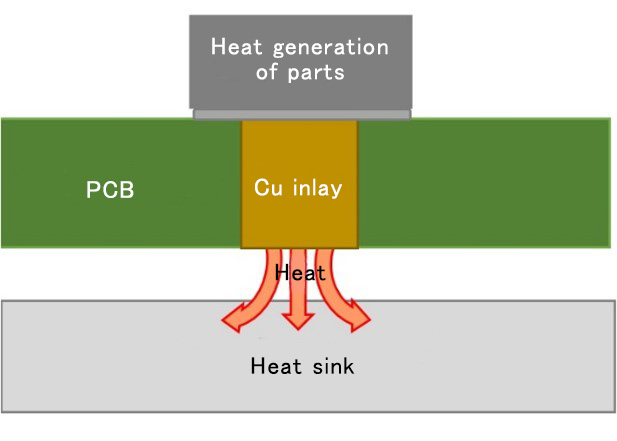

The rapid development of high functionality and high performance electronic devices and the corresponding miniaturization of small components has led to increased heat generation of parts mounted on PCBs. To efficiently release this heat through the heat sinks applied under the PCB, Cu inlays are mounted into the circuit board. These Cu inlay boards have been attracting attention in recent years as a reliable countermeasure for maintaining performance, and extending life time of electronic components.

Compared to press-processed Cu inlays, those manufactured by our company's very own Cold Heading processing are less prone to burrs and sagging, and there is almost no vertical orientation, which make our Cu inlays most suited for usage in Cu inlay substrates. Another positive aspect is, that they can easily be handled and assembled by automated machines.

In addition, as our Cold Heading machines process and form every component by hitting wire material at room temperature, cost reduction can be realized, and – compared to other methods like pressing or cutting processes - material loss does not occur.

By using our own equipment, tooling and automatic processing machines, it is possible to produce Cu inlays with extremely high precision and narrow tolerances. Furthermore, compared to press-processing, the initial jig and mold costs are considerably cheaper, making it possible to reduce the initial costs.

At FINECS, we also offer plating services (Sn, Au and more), taping packaging for use in mounters or other equipment, according to your needs. We provide integrated support, starting from prototyping to mass production, processing in various sizes and shapes that are customized individually to your desire. We are looking forward to receive your order.

specifications

Wire diameter: φ2 to φ6 mm

Overall length: 1 to 3 mm

Shape

Column

Main usage

Heat dissipation for parts and components mounted in printed-circuit boards.

FINECS manufactures copper inlays as well as various other types of heat dissipation parts.

Heat radiating pins for heat sinks

Materials

C1020 and other Cu material

※ Please contact us for questions about material, wire diameter, length, plating or other topics related to Cu inlays.