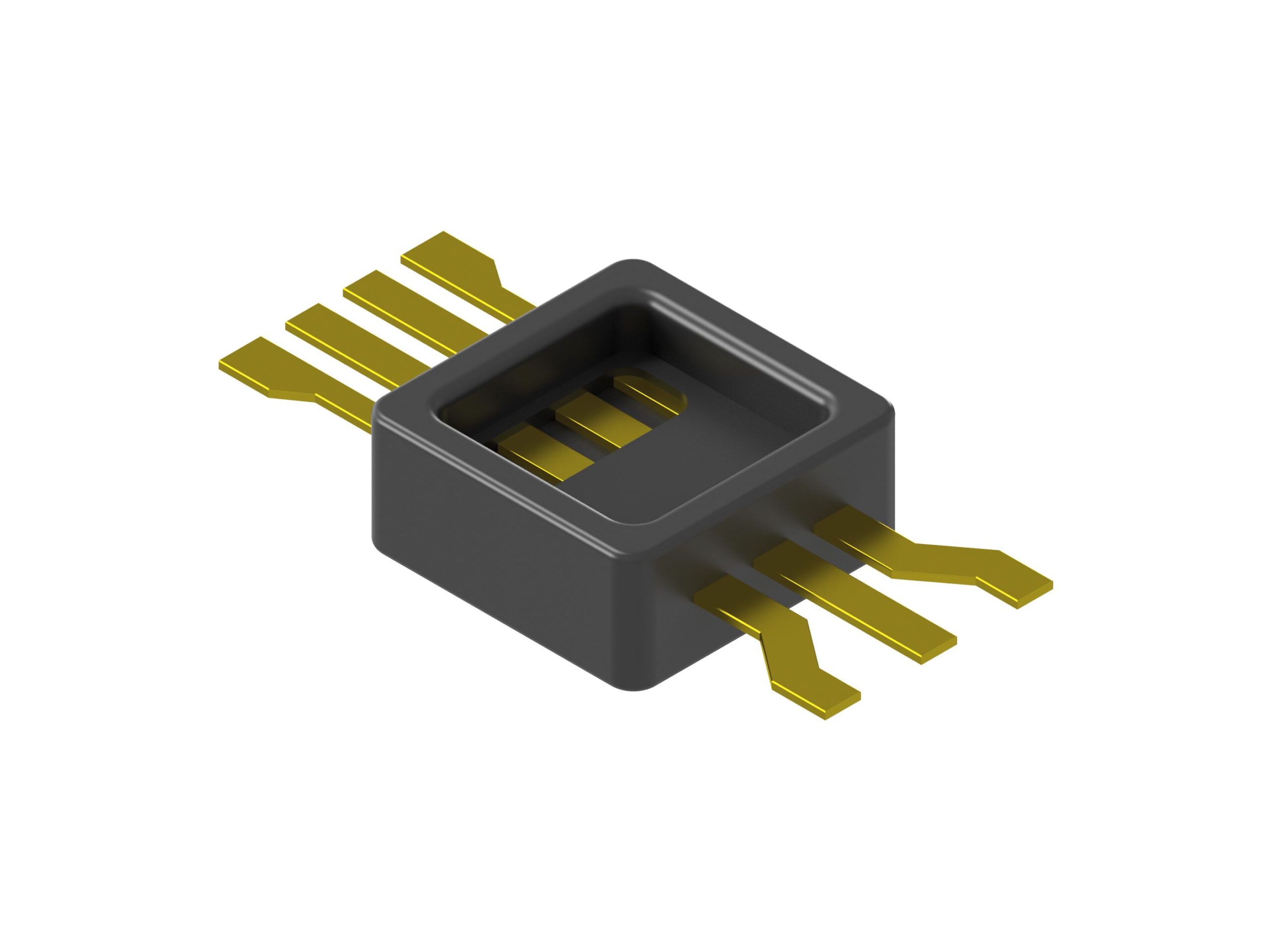

Sensor cases (Press & surface treatment (plating) & insert molding)

We handle mass production quantities from 50K to several 1KK / month.

Main applications

Automotive & consumer sensors

Target product

Automotive sensors

(air) pressure sensors, tactile sensors, temperature sensors, oxygen sensors, speed sensors, LiDAR sensors, seating sensors, and more

Consumer sensors

image sensors, CCD sensors, magnetic sensors, and more

According to our customer’s requests, we make use of our integrated production line – including pressing of metal strips, plating, molding, insert molding, component assembly and more – we provide our high quality parts to sensor manufacturers.

What is a sensor

A sensor is an element or device that collects information on a subject and replaces it with a signal that the machine can handle.

We maintain the industry's top-class production technology for electronic components and provide satisfaction that exceeds customer expectations.

At FINECS, we make use of our integrated production line – including pressing of metal strips, plating, molding, insert molding, component assembly and more

Our proposal

We manufacture our electronic components via an integrated production line. All processes are kept close to each other, enabling us to guarantee quick feedback of product quality between each step. By continuously enhancing the technology of our pressing and molding equipment we are able to reduce scattering to a minimum. We strive to further improve the capabilities of our processes – to create self-completing processes with minimum inspection load, so that we achieve a production which does not require 100% of the parts to be put under inspection.

Through enhancing product quality, we provide global competitiveness keeping lead time, costs and speed in a perfect balance. In addition, we keep pushing our internal automation development using flexible robots, automated processing machines, image inspection equipment and more to reduce costs and work load of our employees, but also to improve speed and quality of our products.

Shape

Regarding any kind of signal terminal for sensors, we can manufacture lead frames using our pressing technology. We can also add surface treatment (plating: full, partial, hoop) or insert molding to create sensor cases inside our integrated production line.

We can also supply hoop leadframes by pressing and plating.

Material

Pressed terminals

material for lead frames: phosphor bronze, pure copper, brass, etc.

Molded parts

PPS (thermoplastic resin), heat resistance 9T nylon (heat resistance), LCP, etc.

Plating:

Ni, Cu (both base)

Soft Au, Ag, Sn (finish)

※ other material possible. Please contact us.

Plating

To make wire bonding possible, the most common type of plating for lead frames is Ni (base) + soft Au (finish). With a view on the financial side, we offer partial plating for soft Au.

Q&A

Q:Do you offer prototyping?

A:Yes.

Q:What is the MOQ for mass production?

A:We handle quantities between 50K and 1KK per month.

Q:Which is the maximum size you can handle?

A:About 60x60mm.

Q:Is tooling to be prepared beforehand?

A:Yes. According to your needs we offer customized in-house tooling or ordered tooling for pressing and molding.

Q:How heavy are the molding machines you use?

A:The small machines weigh 7t or 10t, the middle class machines around 40t. We can also prepare machines of higher weight.

Q:Which manufacturing processes do you offer?

A:Pressing, surface treatment (plating), insert molding, automated assembly, heat treatment, automated image inspection and more. Please let us know your preferences.

Regarding process design or product dimensions, we make you the best offer considering quality,

costs and productivity. We are always available for online consulting and meeting, so please feel free to contact us any time.

Related Products

-

- * Specifications, materials, and other details are available upon request.