Electrode Terminals of Rechargeable Battery

This product is manufactured and sold by FINECS.

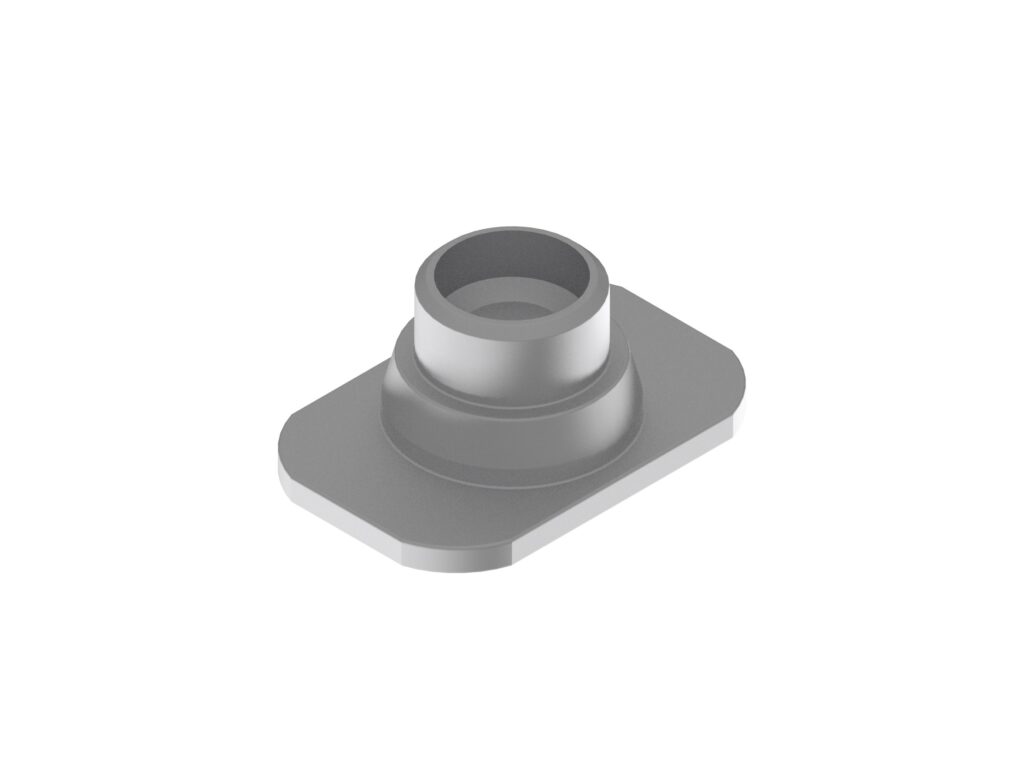

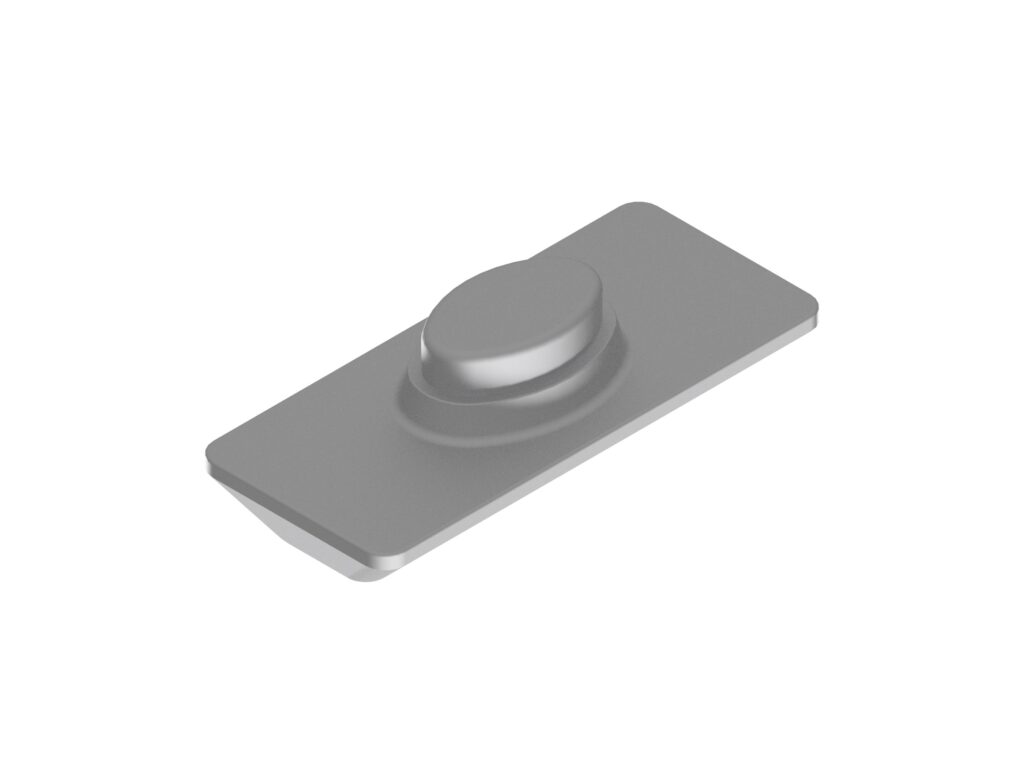

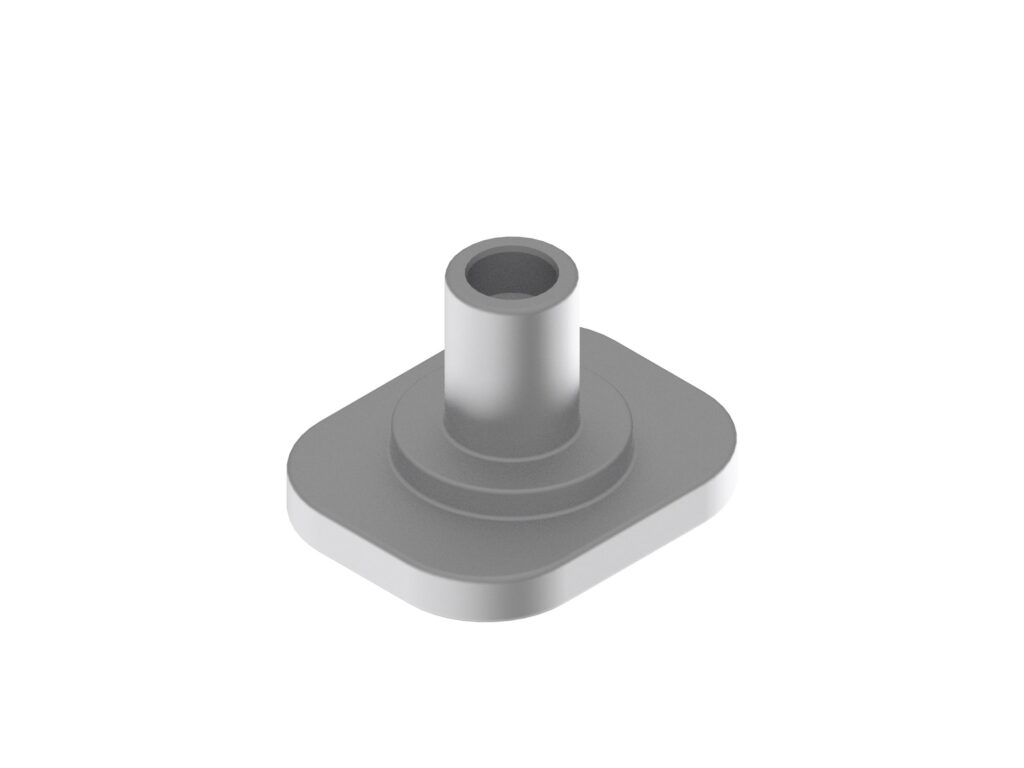

Terminals for electrodes for rechargeable batteries (shape examples)

Reference standard

Aluminum terminal

Shaft diameter φ3.0~φ10.0、Head diameter φ3.0~φ20.0

Copper terminal

Shaft diameter φ3.0~φ10.0、Head diameter φ3.0~φ15.0

Main usage

Positive / Negative Electrode Terminals.

Our products are used for the positive and negative electrodes of secondary batteries (lithium ion batteries, etc.) installed in next-generation vehicles such as HEVs (hybrid vehicles), PHVs (plug-in hybrid vehicles), and EVs (electric vehicles). We are also putting effort in the manufacturing of terminals for all-solid-state batteries.

In addition, the current collector plates and terminals are also used in capacitors which work as power assistants during vehicle acceleration, energy regeneration, engine starting, and more.

In accordance with “CASE”, the recent years showed a rapid improvement of performance and fuel efficiency of automobiles, leading to further miniaturization and weight reduction of components. Do not hesitate to contact us, if you are looking for high quality current collector plates or terminals to fulfill these requirements.

Characteristics

This is a terminal used for cathodes / anodes of automotive or consumer rechargeable battery (e.g. nickel hydrogen batteries, lithium-ion batteries, and more)

We also offer in-vehicle lithium-ion secondary batteries, as well as headed or pressed current collector plates and terminals for capacitors (condensers).

Based on our current manufacturing records of secondary battery terminals, we are also planning to produce terminals for all-solid-state batteries. If you are considering the use of terminals for all-solid-state batteries, please feel free to contact us.

Characteristics of automotive rechargeable battery terminals (car battery terminal) manufactured through our Heading Technology.

Automotive rechargeable batteries consist of a positive and a negative electrode, where copper and aluminum are used as terminal parts. At FINECS, we use our Heading Technology to produce those Electrode Terminals from copper or aluminum wires (round wires). Because the Heading process leaves nearly no waste at all, it is a very environmentally friendly production method with low material costs. The Electrode Terminals are used to seal the battery housing.

Strengths of FINECS' Rechargeable Battery Terminals

Accumulation of many years of experience in the field of Heading Technology, and sales records regarding in-vehicle lithium-ion battery manufacturers.

Becoming world's top class through accumulating experience, know-how and technology for more than 50 years.

As a top-class manufacturer, we will make optimal proposals from material selection to processing conditions according to your specifications.

Our rechargeable battery terminals are provided to lithium-ion battery (battery) manufacturers, and are well received and trusted for their excellent surface condition.

FINECS' burr-free processing.

In terms of quality, burrs and contamination are very important topics for automotive rechargeable batteries.For our special Heading Technology, we handle the full process from tool designing to the actual manufacturing process design ourselves. Therefore, we are able to produce with only a minimum of burr occurrence. Finally, we will offer you very clean Electrode Terminals for your automotive rechargeable batteries (car battery terminals).In addition, during material cutting and heading, the optimum cut surface is achieved by adjusting the shape of the cutting edge, processing conditions, and die dimensions.

Great amount of Heading Machines

We have a large number of Heading Processing Machines (2D3B, 4D5B). We will select the most suitable processing machine according to the product's shape and wire diameter.

Automated clean production line

According to your needs, we can also propose an automated full production line, including the processing machines, cleaning machines, and image inspection equipment. By automating, it is possible to eliminate work mistakes, reduce manufacturing costs, and build a self-process-completed manufacturing line.

In addition, we can design the image inspection device to measure all points you request.

By laying a great focus on non-contamination, we produce on a environmentally friendly and well-maintained manufacturing floor, thus ensure in-vehicle quality.

よくあるご質問(Q&A)

Q:圧造(冷間鍛造)加工以外の製品の対応できますか?

A:形状によってはプレス加工での対応も可能です。

Q:バリ・コンタミを無くすための取り組みをしていますか?

A:ファインネクス独自の金型・工程設計と加工技術により圧造加工(冷間鍛造)工程でのバリ、カスの発生を極力低減しております。また当社では銅材とアルミ材の加工工程を別フロアに分け、コンタミ混入への考慮も行っています。

※一部製品においては、材料の加工前のインライン洗浄や、簡易クリーンルーム内での画像検査を実施しております。

Q:国内生産ですか?

A:現在すべて国内富山県内の工場で生産しております。

Q:海外での購入はできますか?

A:国内生産品を輸出し、海外のお客様への納入が可能です。

Q:標準品ですか?

A:全てお客様のご要求仕様に基づくカスタム品です。個々のご要望に合わせて対応が可能です。

Q:新規注文から納品までのリードタイムはどのくらいですか?

A:様々な形状にも対応できる各種圧造設備を複数台保有しております。また試作機も保有しており、自社で金型設計・製作も行いますので、試作のご依頼から納入までを最短スケジュールで提案致します。まずはお気軽にお問い合わせください。

Q:圧造(冷間鍛造)では、どこまでの精度管理が可能ですか?

A:材質・形状にもよりますが、µmオーダーでの加工実績もございます。

* If you have any requests regarding wire diameter, length, plating, quality, etc., please feel free to contact us. We are happy to help you.