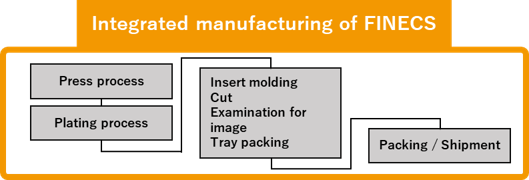

Integrated Manufacturing of molded parts

The Integrated Manufacturing at FINECS and FINE difference

Integrated manufacturing from pressing, through to surface treatment, through to insert-molding.

Our many years of experience in the processing of terminal connectors and their surface treatment have enabled an insert-molding that has a competitive advantage over QCD through the use of our original, unique manufacturing methods.

In particular, the soft gold-plating lines in our factories (partial plating available) which are intended for semiconductors that require a uniform surface-state quality and can be wire bonded, has made our plating technologies more competitive. Also can partial plating for lead frames using wire bonding.

The concept of no burr/short shot achieved through the use of technologies acquired in narrow pitch molding.

Our concept of process design avoids repair work as much as possible by attaining substantially “zero” burr/short shot in the insert-molding.

We perform flow analysis of the molding materials as part of the concept to use burr/short shot free molding technologies.

These process design and mold technologies will provide the insert molding lines that are stable and trouble-free.

Automation technologies and in-line image inspection technologies have been established through our use of self-manufactured automatic machines.

The use of automatic machines that we manufacture ourselves has enabled more labor-saving line design with a lower in-process defective rate, which has resulted in us achieving low-cost insert-molding.

Among other things, the use of our own in-line image inspection/detection technology which we developed during the manufacture and assembly of fine narrow-pitch connectors has enabled low-cost and reliable inspection processes without the need for manpower.

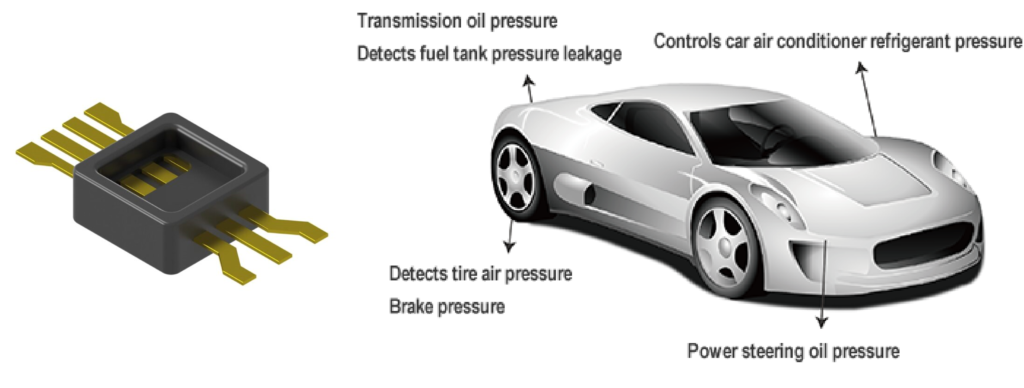

OEM: Automotive pressure sensor

Applications for automotive pressure sensors (image)

All different types of sensors are implemented into cars, all of them have important tasks. Their use is increasing daily, thus making sensors an indispensable part of modern vehicles.

Creating housings and lead frames for these sensors as our OEM production line. Utilizing our experience and technology in the field of super-narrow pitch connectors, we can offer you sensor parts of the highest quality. (OEM only)

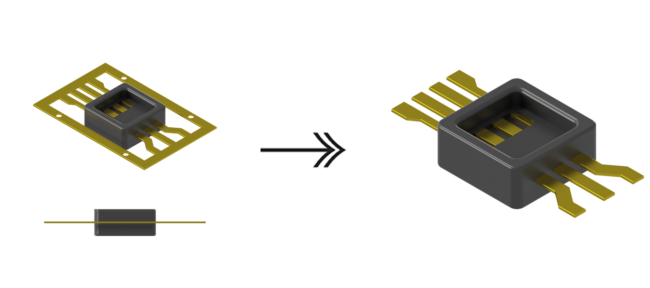

OEM: Automotive pressure sensors (components)

【Characteristics】

After making lead frames out of Hoop material, the pressed metal is undergoing partial soft Au plating in one of our continuous plating lines. Finally, it is encased with a sensor housing by Hoop Insert Molding.

We can produce lead frames from a wide variety of metals, such as phosphor bronze, pure copper or brass, so please feel free to contact us for more information.

The housing material, LCP or PPS are most common, because of their very good heat resistance and isolation characteristics, which are highly requested.

The typical plating for lead frames consists of the combination of Ni underplating + Au plating. If wire bonding is your target, we offer you a soft Au plating. Soft Au plating is one specialty of our in-house plating line, which can also be done as partial plating. It captivates through high quality at low costs at once.

For more details:【Go to: Surface treatment (plating)】

We can also offer different kinds of plating, so please contact us for detail.

OEM: Automotive & Consumer ECU connectors

Connectors using wire-made terminals (OEM)

Connectors using wire-made terminals (OEM)

【Characteristics】

We offer OEM production of connectors that are using wire-made terminals. These terminals are all self-made through our long experience of cold heading pin manufacturing.

Our OEM production captivates through outstanding cost management, as we offer you the full service of our Integrated Manufacturing Line, starting with the processing of terminals and ending with the Insertion Molding into connector housings.

we also handle the press-fitting and assembling of terminals into connector housings as OEM. This can be done at an even cheaper level with larger quantities, but has its disadvantages over Insertion Molding in terms of precise tolerance management.

As we do all press-fitting by self-designing and usage of self-made equipment, we are able to handle all different kinds of specifications.

In addition to brass, phosphor bronze and pure copper can be used for insert molding terminals. Please feel free to ask us for more information.

It is also possible to provide a shape to prevent the terminals from falling off and moving after insert molding. We can offer you the optimum shape according to your application and requested size.

The housing material, LCP or PPS are most common, because of their very good isolation characteristics, which are highly requested.

The most common type of terminal plating is Sn plating on Ni base or Cu base that has undergone reflow treatment, but please contact if you wish any other conditions like Au plating.

Packing types, we offer reel winding (remaining in hoop shape), embossed taping, trays and more.

* Depending on the size, several types might not be applicable.

For more information:Go to【Connector terminals/Connector pins】

Connectors using pressed terminals (OEM)

【Characteristics】

Our integrated manufacturing line: press working → surface treatment → insert molding of terminals into the connector housing.

In addition to brass, phosphor bronze and pure copper can be used for the insert molding of terminals, so please ask us for more information.

Connector OEM is available from 0.4mm pitch.

The housing material, LCP or PPS are most common, because of their very good isolation characteristics, which are highly requested.

The plating applied to the terminals needs to be resistant to friction during insertion and pulling, which is why Ni base + hard Au plating is optimal.

Also,Au plating can be as partial plating.

In addition, according to your request we can perform Sn or Ni plating, so please contact us for more information.

The packing types, we offer reel winding (remaining in hoop shape), embossed taping, trays and more.

* Depending on the size, several types might not be applicable.

For more information:Go to【Connector terminals (press-working and surface treatment)】

The OEM above shows only a part of our OEM capacities. We can offer products for a wide variety of applications and in all kinds of shapes.